Silt stopping and discharging technology and construction method for separating debris flow by adopting dynamic silt stopping reservoir capacity

A construction method and mud-rock flow technology, which is applied in sea area engineering, water conservancy engineering, construction, etc., can solve the problems of barrier structure erosion, limited interception effect, aggravating mud-rock flow disasters, etc., and achieve the effect of improving safety and improving operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

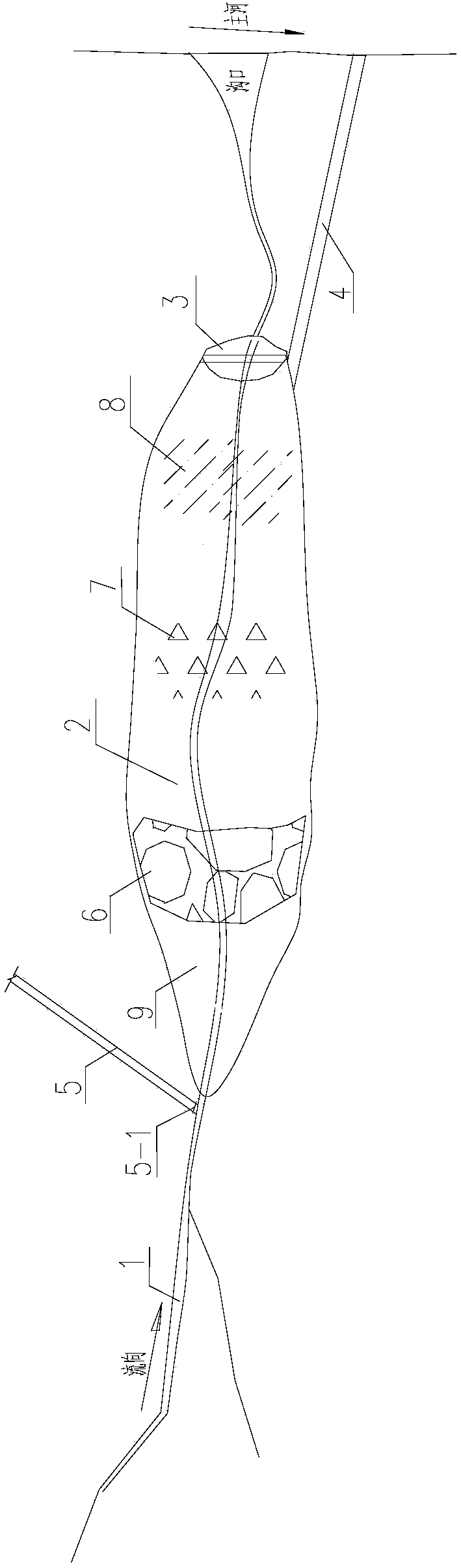

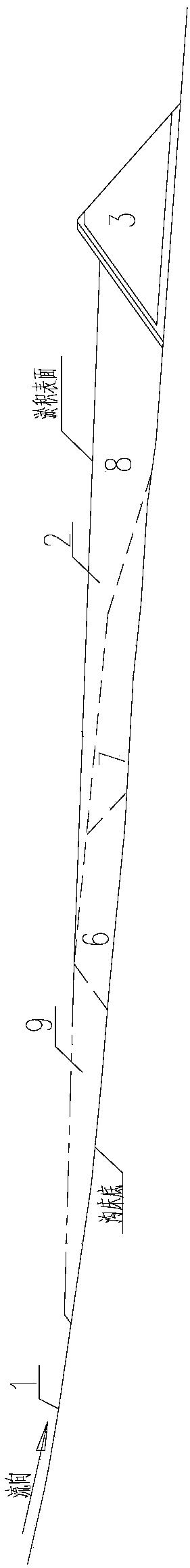

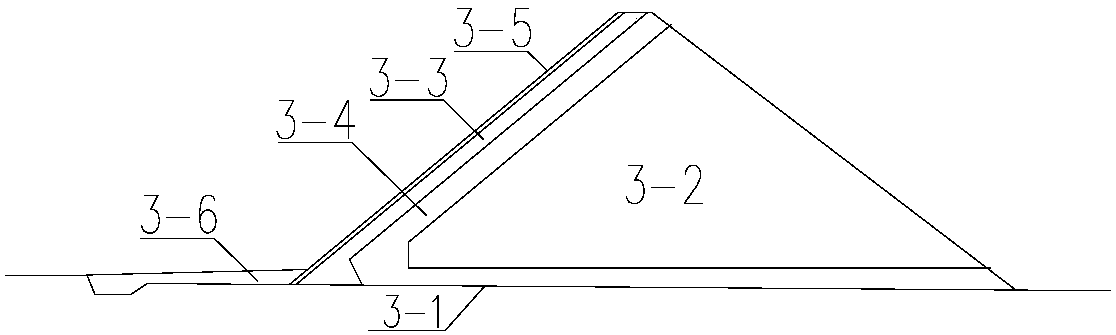

[0022] like figure 1 , figure 2 As shown, this embodiment is a drainage structure that uses dynamic silt storage capacity to separate debris flow. It has the original debris flow ditch 1, and a retaining dam 3 to block the debris flow ditch 1 is set at the gentler slope of the ditch bed of the debris flow ditch 1. , to form a debris flow silting storage capacity 2 upstream of the retaining dam 3, the debris flow silting storage capacity 2 is greater than 2 to 5 times the total amount of a debris flow, and the reservoir surface width of the debris flow silting storage capacity 2 is greater than 5 to 10 times the width of the debris flow ditch 1 . In this example, the drainage channel 4 is connected to the downstream of the debris flow storage capacity 2. The inlet elevation of drainage channel 4 is higher than the expected deposition elevation in the debris flow storage capacity 2. The flow section of drainage channel 4 is designed according to the flood discharge standard an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com