Hot galvanizing automatic assembly line equipment

An assembly line, hot-dip galvanizing technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of failing to meet environmental protection standards, low work efficiency of workers, and messy working environment, etc., to achieve The effect of reducing the loss of zinc liquid material, novel structure, and safe and comfortable working environment for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

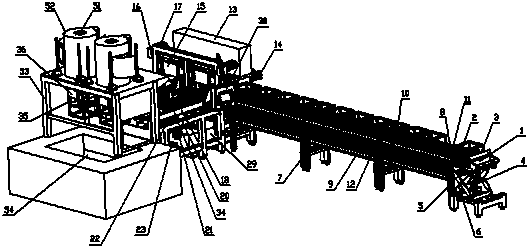

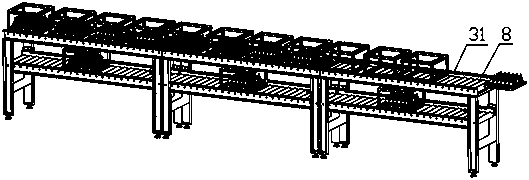

[0017] A hot-dip galvanizing automatic assembly line equipment, including a turning lift 1, a double-station intelligent circulation feeding and discharging device, a double-station eight-claw multifunctional manipulator and a tunnel heating device 31. The turning lift 1 includes a turning lift base and The turning lift platform that is connected on the top of the turning lift base by the scissor fork lifting plate 6 is connected with the turning oil cylinder 4 and the lifting oil cylinder 5 between the turning lifting platform and the turning lifting platform, and the turning lifting platform is provided with hooks 2 and 2 that are used to grasp the work frame The hook control cylinder 3 connected with the hook 2, the flip elevator 1 is connected with the double-station intelligent circulation feeding and discharging device through the raceway frame 7 provided with the upper raceway 8 and the lower raceway 9, the upper raceway 8 and the lower raceway The track 9 is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com