Automatic conveying device

A technology of automatic transportation and automatic guidance, applied in the field of steel wire products, can solve the problems of heavy workload, low work efficiency and high production cost of workers, and achieve the effect of reducing labor intensity, improving production efficiency and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

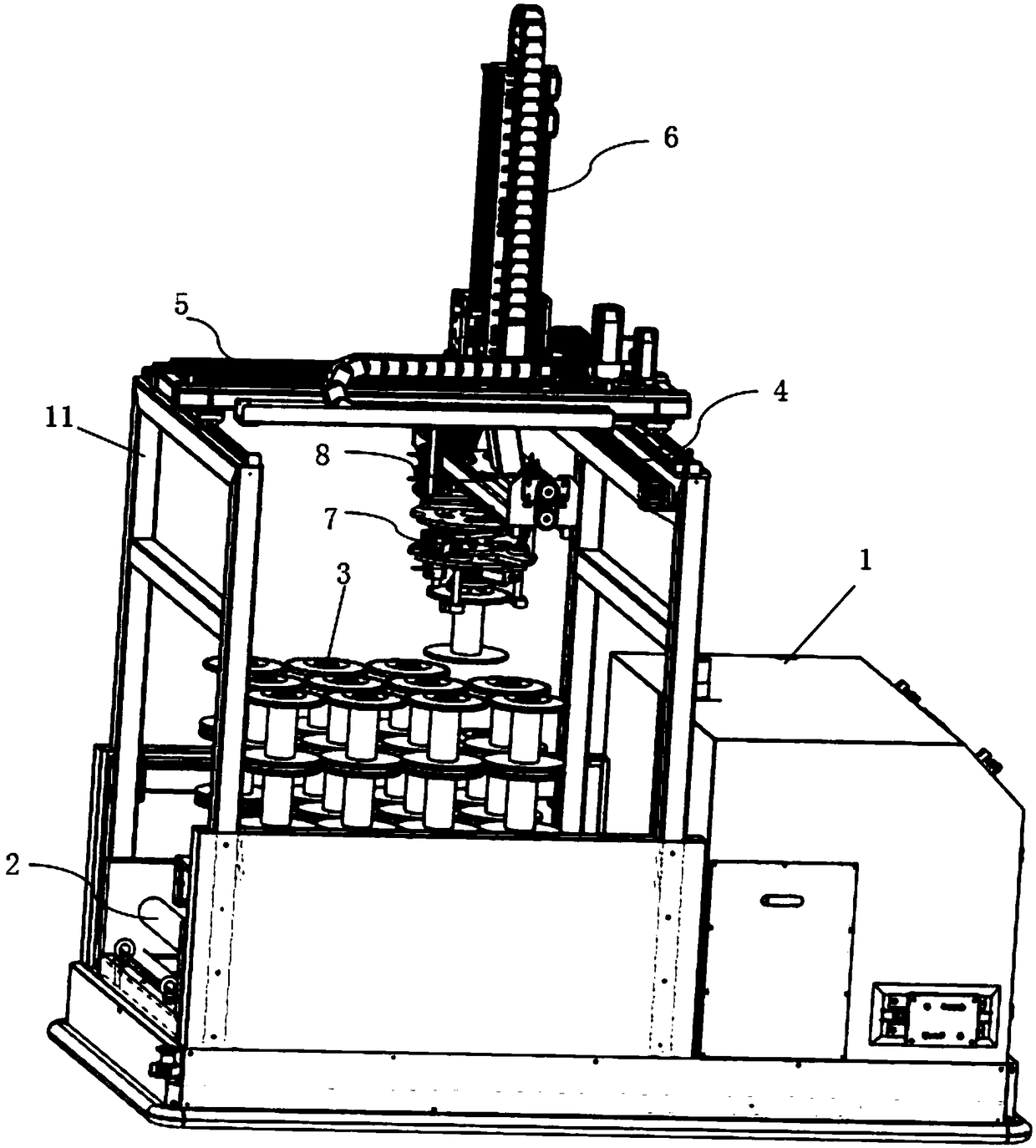

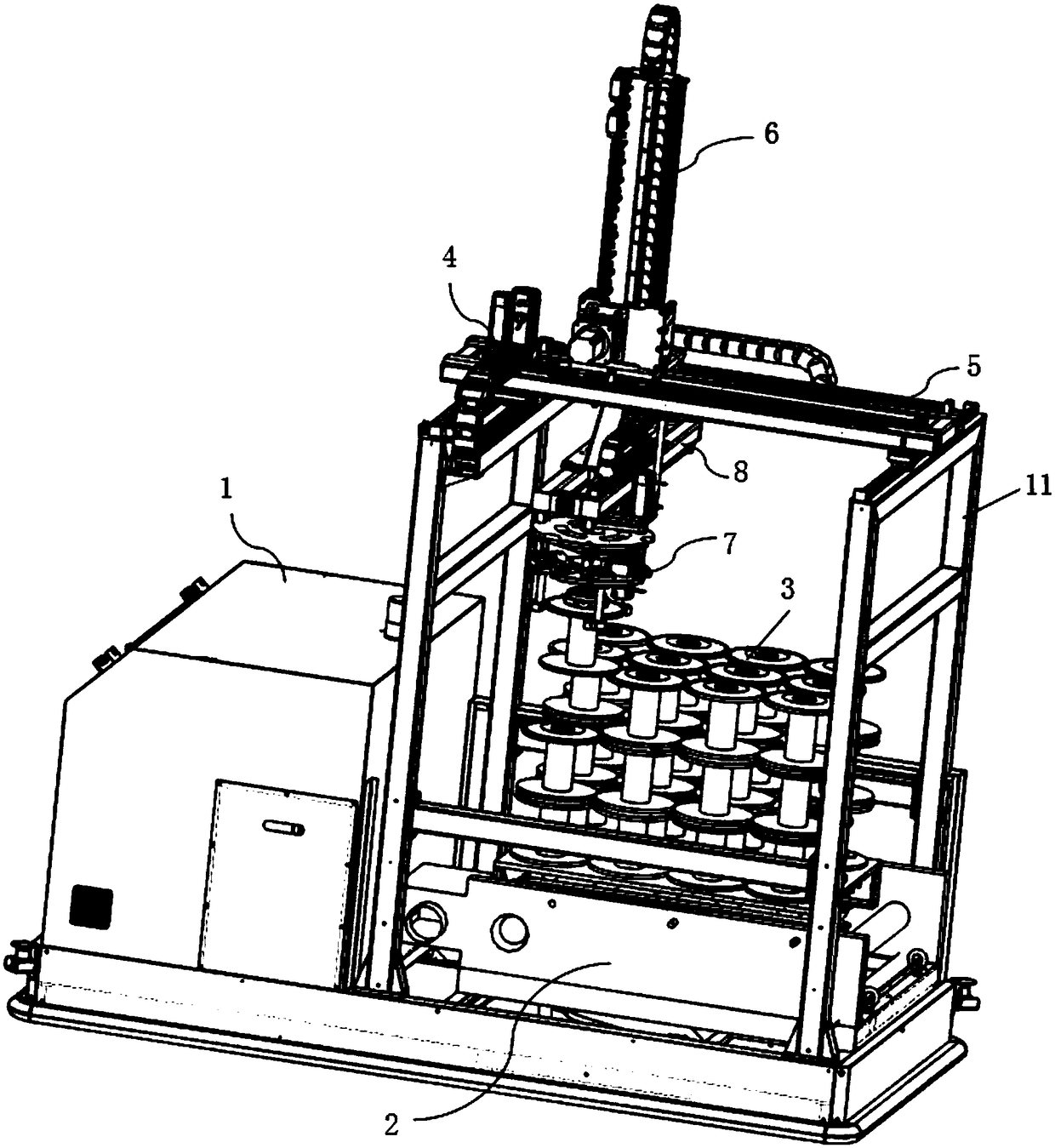

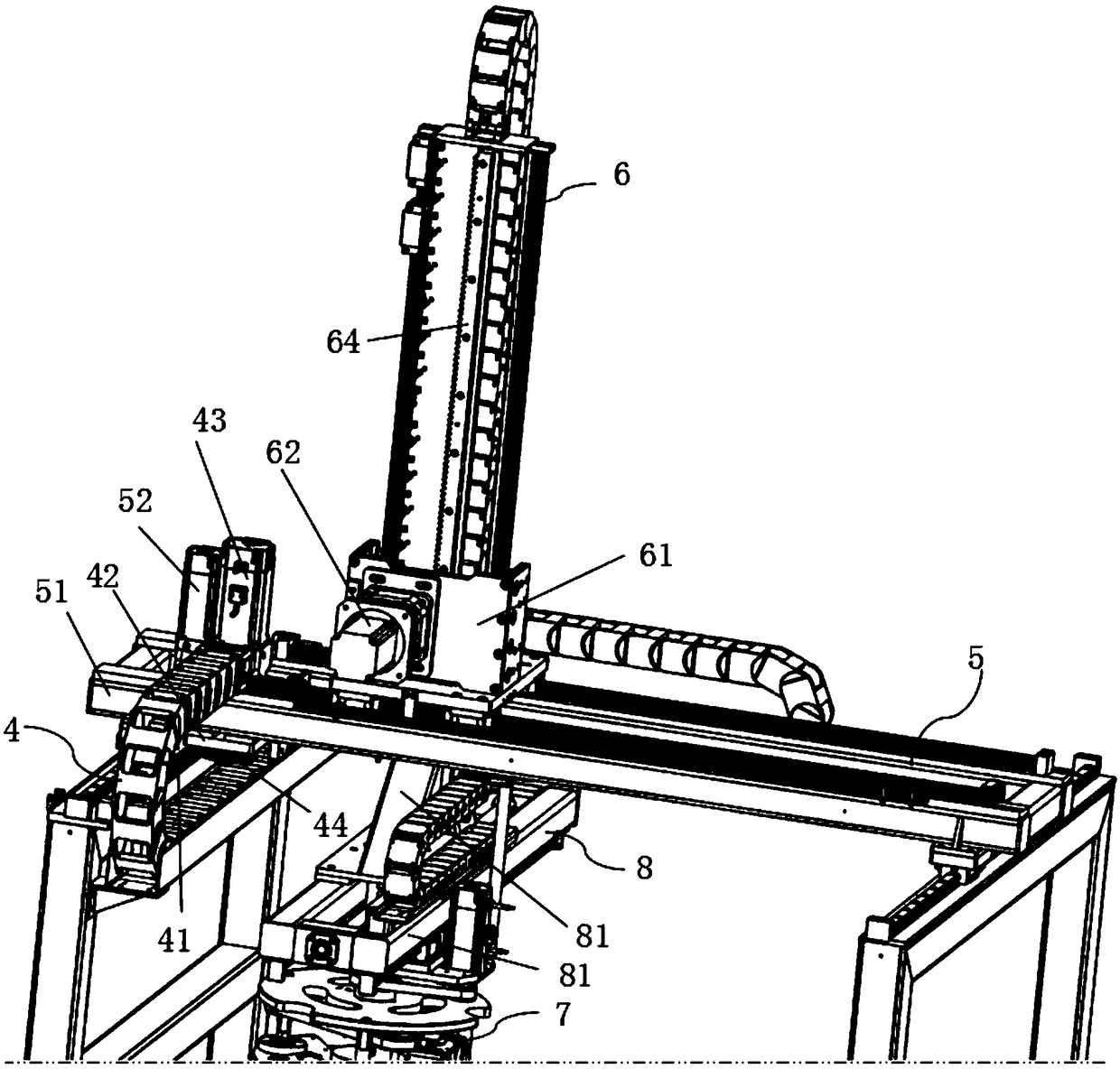

[0075] Such as Figure 1-Figure 2 As shown, this embodiment provides an automatic conveying device, including an automatic guided transport vehicle 1 , a conveying unit 2 , a Y-direction moving unit 4 , an X-direction moving unit 5 , a Z-direction moving unit 6 and a gripping unit 7 . Among them, the automatic guided transport vehicle 1 (AGV, Automated Guided Vehicle) refers to a transport vehicle equipped with automatic guidance devices such as electromagnetic or optical, which can drive along the prescribed guiding path, and has safety protection and various transfer functions. . The automatic guided transport vehicle 1 itself has a control system, and the control systems for other units in this embodiment are all integrated into the control system of the automatic guided transport vehicle 1 . I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com