Luggage production device with vacuumizing function

A manufacturing device and vacuum pumping technology, which is applied in the field of luggage manufacturing equipment, can solve the problems of inaccurate preheating temperature and failure of the luggage shell to absorb plastic, and achieve the effect of being easy to absorb plastic and be easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

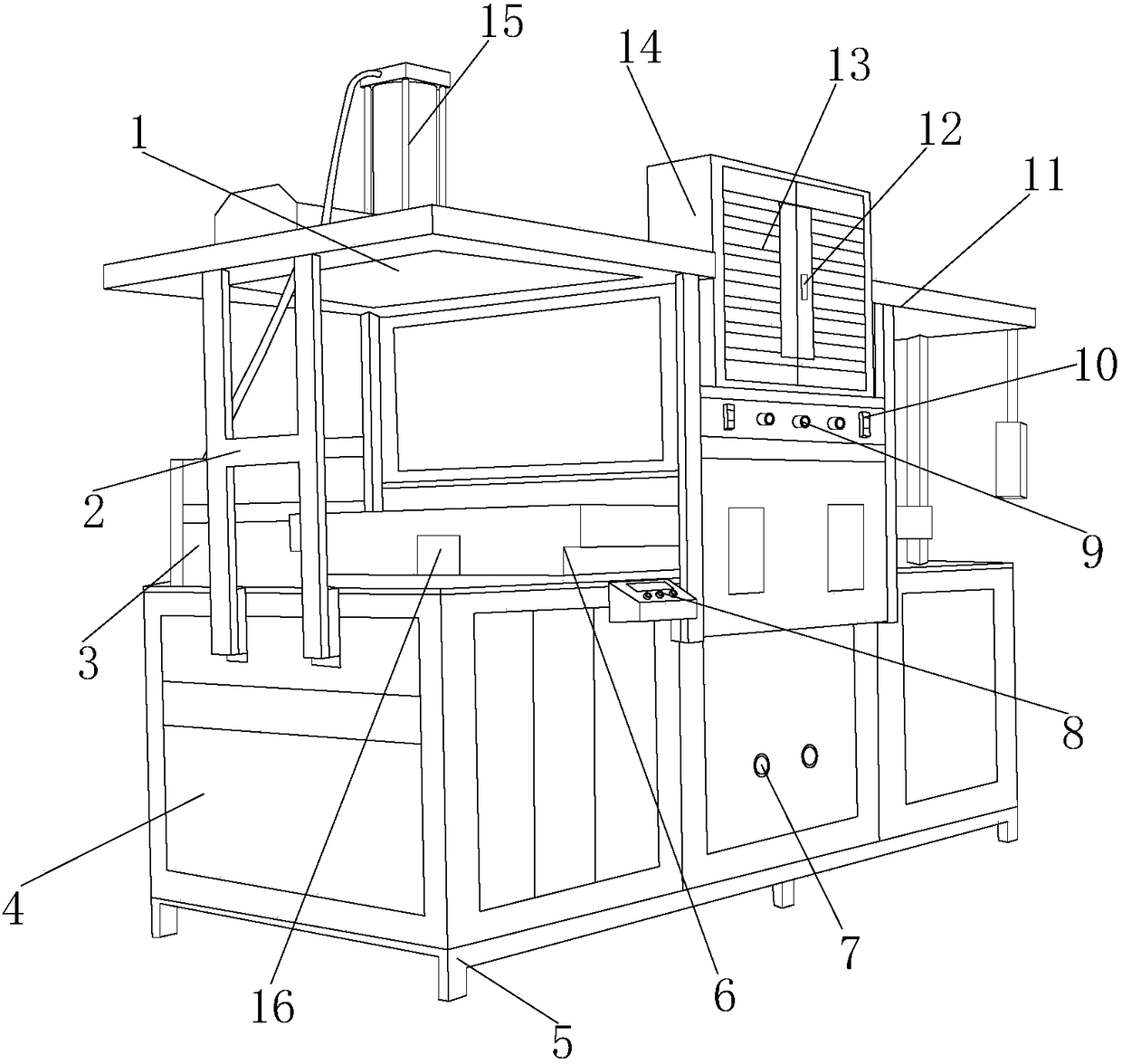

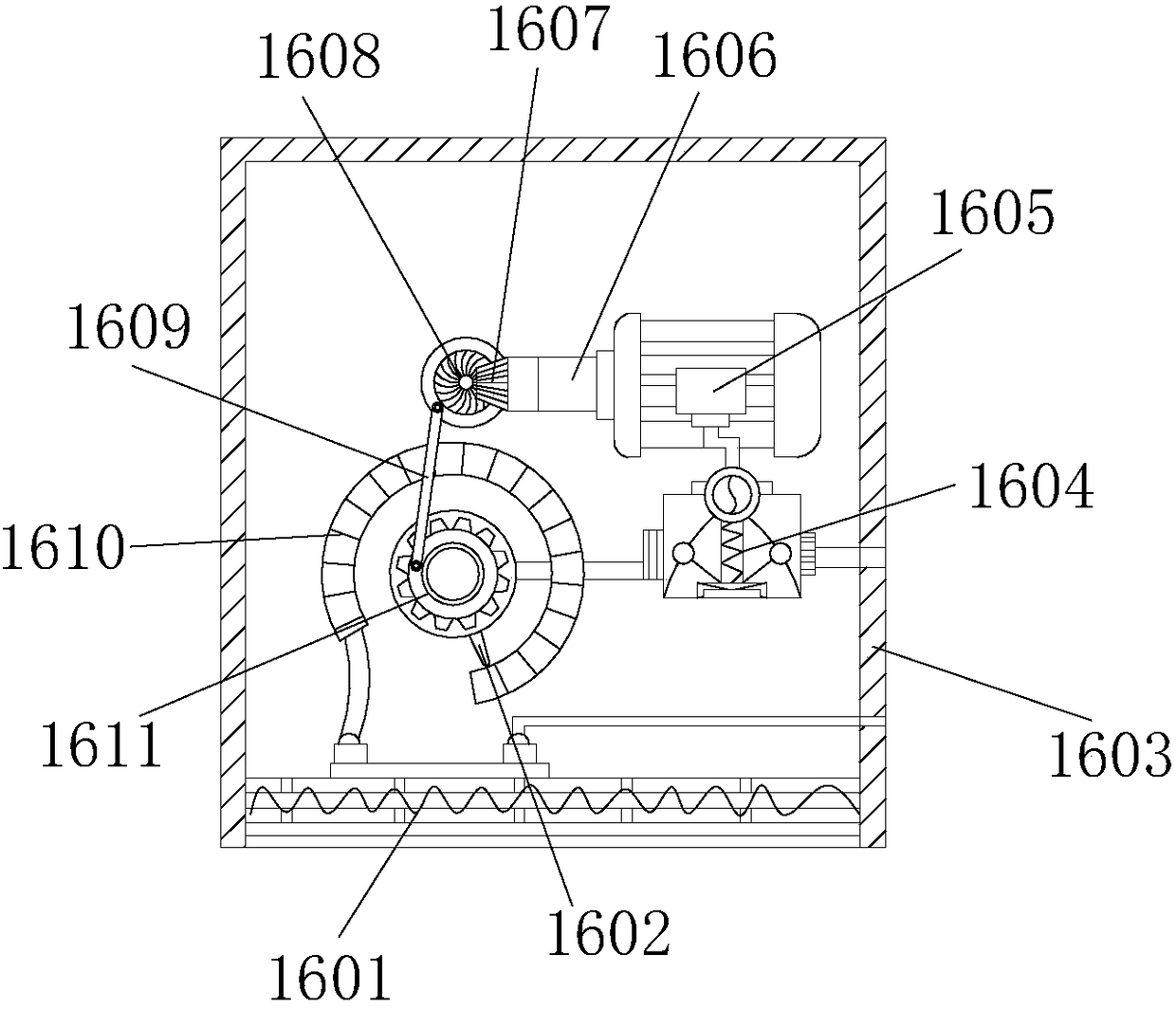

[0019] see figure 1 , figure 2 , the present invention provides a technical solution for a luggage manufacturing device with a vacuum function: its structure includes a storage board 1, a support frame 2, a mounting block 3, a main body 4, a support foot 5, a cover plate 6, a display instrument 7, and a controller 8 , adjustment button 9, connector 10, bracket 11, handle 12, cabinet door 13, control cabinet 14, vacuum pump 15, adjustable heater 16, the upper surface of the main body 4 is attached to the bottom surface of the installation block 3, the The bottom surface of the main body 4 is welded with the supporting feet 5, the outer surface of the main body 4 is embedded with a display instrument 7, the upper surface of the main body 4 is att...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com