Electromagnetic sulfuration system

A vulcanization system and electromagnetic technology, applied in the field of vulcanization of rubber bearings, can solve problems such as long processing vulcanization time, uneven vulcanization of supports, and infeasibility, and achieve the effect of improving vulcanization efficiency and vulcanization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

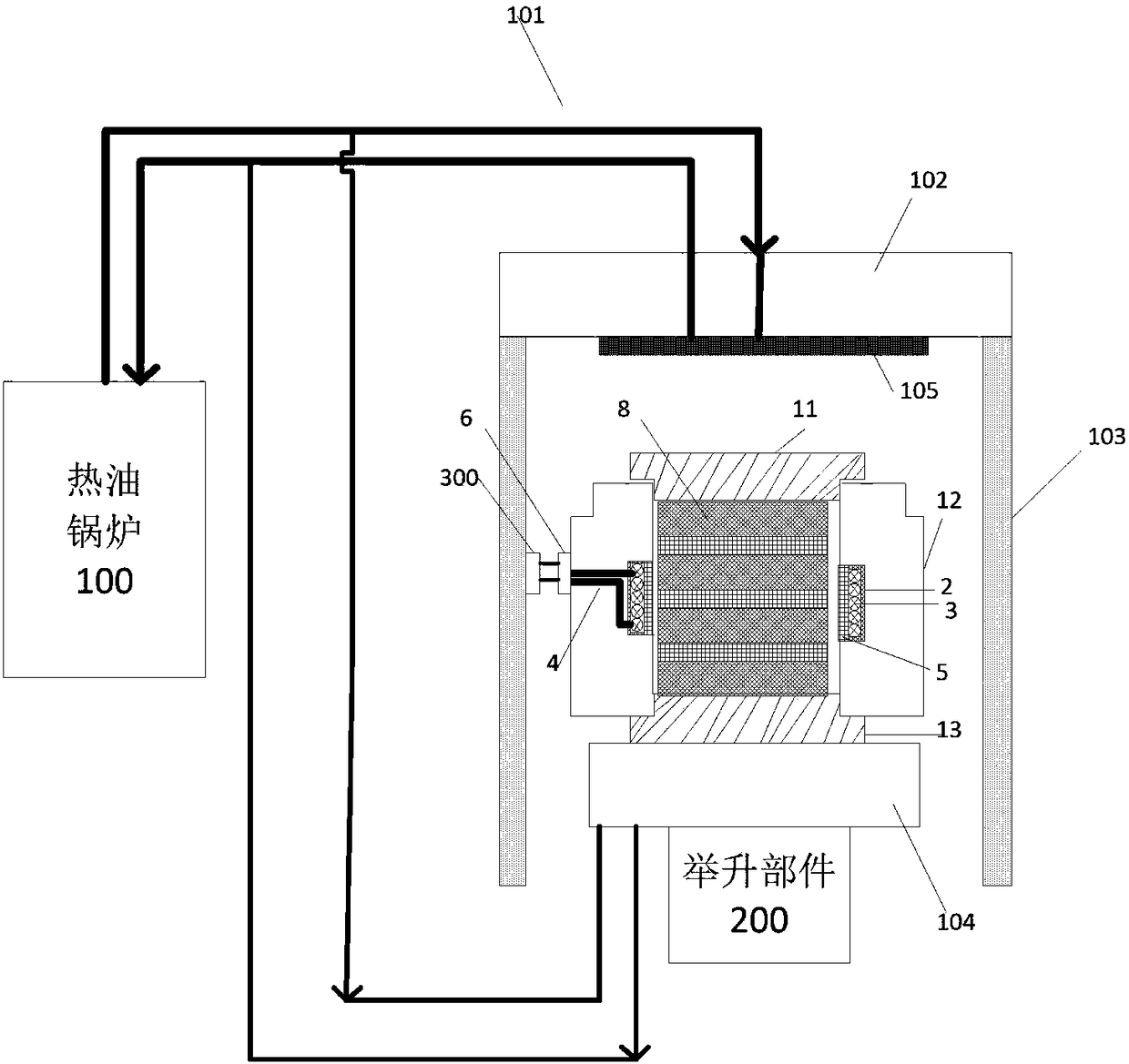

[0032] This embodiment provides an electromagnetic vulcanization system, including a vulcanizer and a vulcanization mold, the vulcanizer includes a thermal oil boiler 100, a transmission pipeline 101 and a press, and heat transfer oil is in the thermal oil boiler 100 and the transmission pipeline 101 Flow, wherein the thermal oil boiler 100 heats the heat transfer oil to a preset temperature; the preset temperature is set according to the vulcanization temperature, which can be determined according to the selection method in the prior art. The transmission pipeline 101 is connected between the thermal oil boiler 100 and the upper heating plate 105, and between the thermal oil boiler 100 and the lower heating plate 104, and the heat transfer oil at a preset temperature is transmitted through the transmission pipeline 101 To the upper heating plate 105 and the lower heating plate 104, the upper heating plate 105 and the lower heating plate 104 are heated. Wherein, in order to co...

Embodiment 2

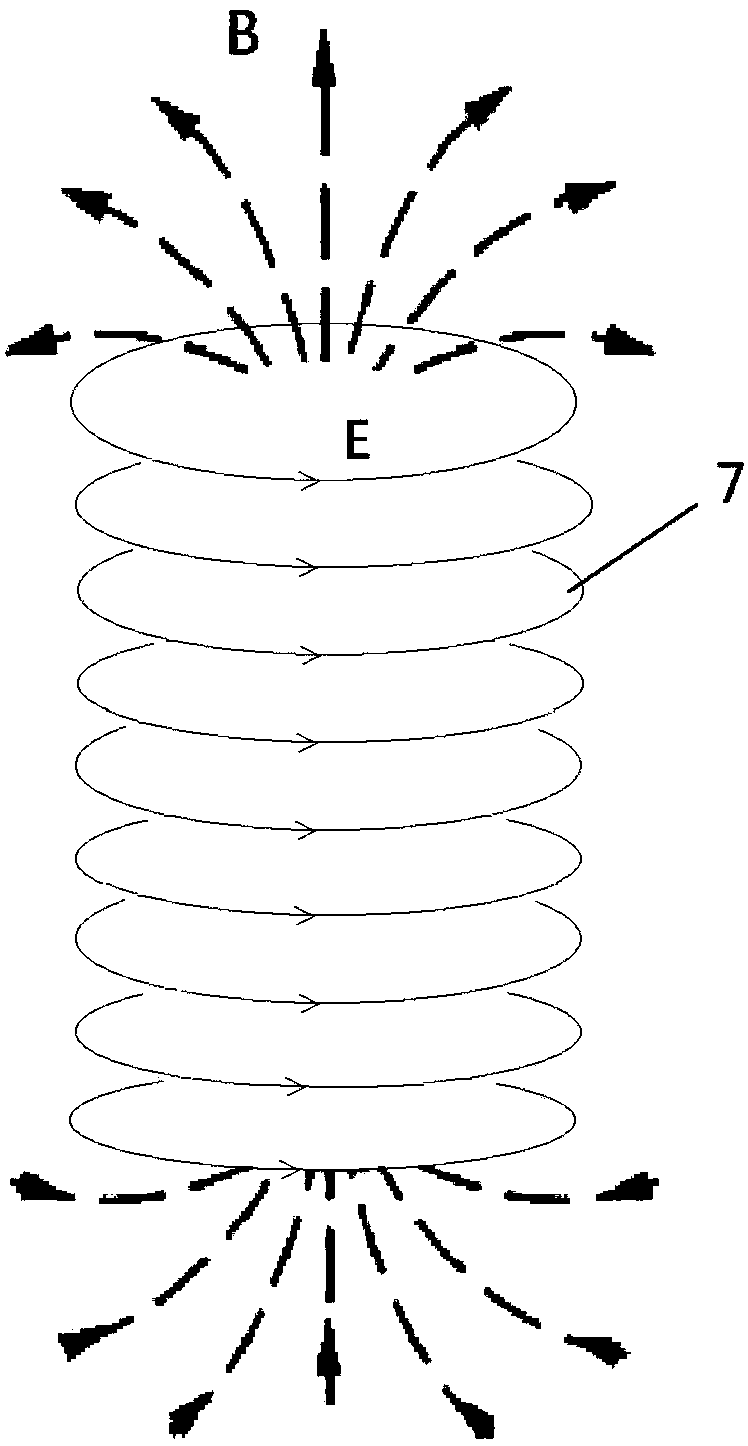

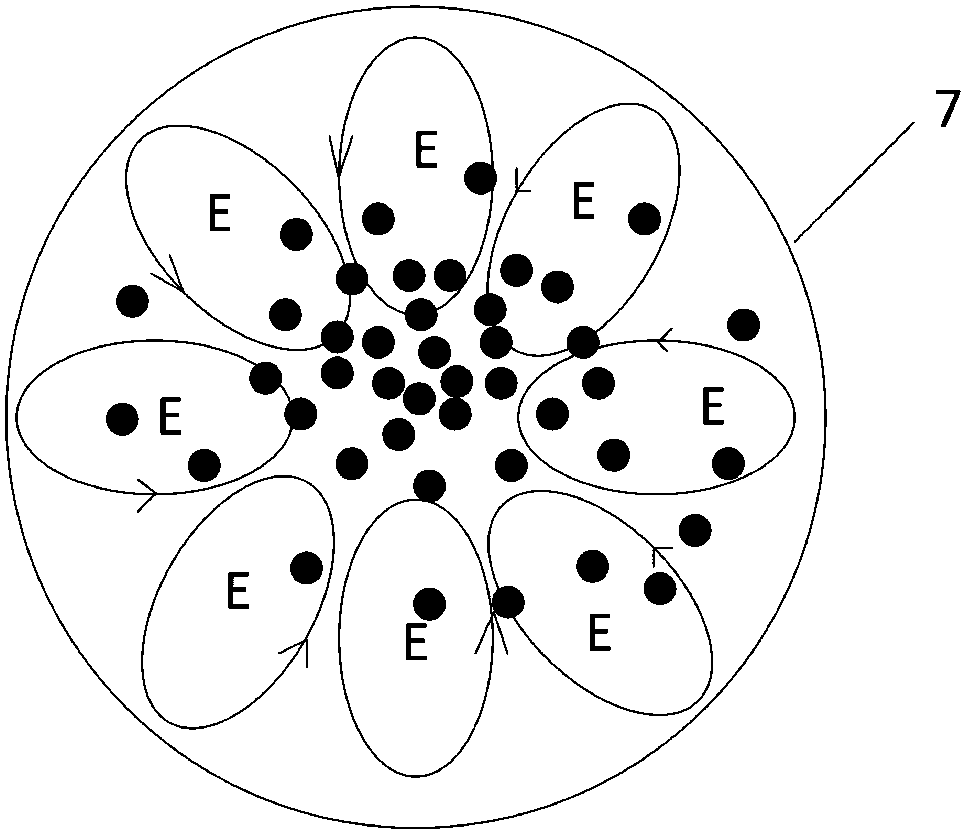

[0038] In the electromagnetic vulcanization system provided in this embodiment, the diagram of the first electromagnetic field inside the vulcanization mold is as follows figure 2 As shown, since the energized coil 3 is arranged in the outer circumferential direction of the steel plate 7, after it acts on the steel plate 7, the direction of the electric field is distributed along the circumferential direction of the steel plate 7, and the direction of the magnetic field is the direction perpendicular to the plane of the steel plate 7. The distribution of magnetic force lines and electric field lines is schematically drawn in the figure. After the first electromagnetic field acts on the steel plate 7, the edge of the steel plate near the position of the energized coil 3 can be heated rapidly, and the width of the edge is about 10 mm. Since the steel plate 7 is made of metal, if its edge is heated rapidly, its center can also be heated relatively quickly through the heat conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com