Pulverization device for recovering plastic

A crushing equipment and plastic recycling technology, which is applied in the field of crushing equipment and plastic recycling crushing equipment, can solve the problems of inability to handle crushing, hidden dangers to personal safety of staff, and low practicability, so as to achieve high use effect and prevent plastic chips from splashing , The crushing effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

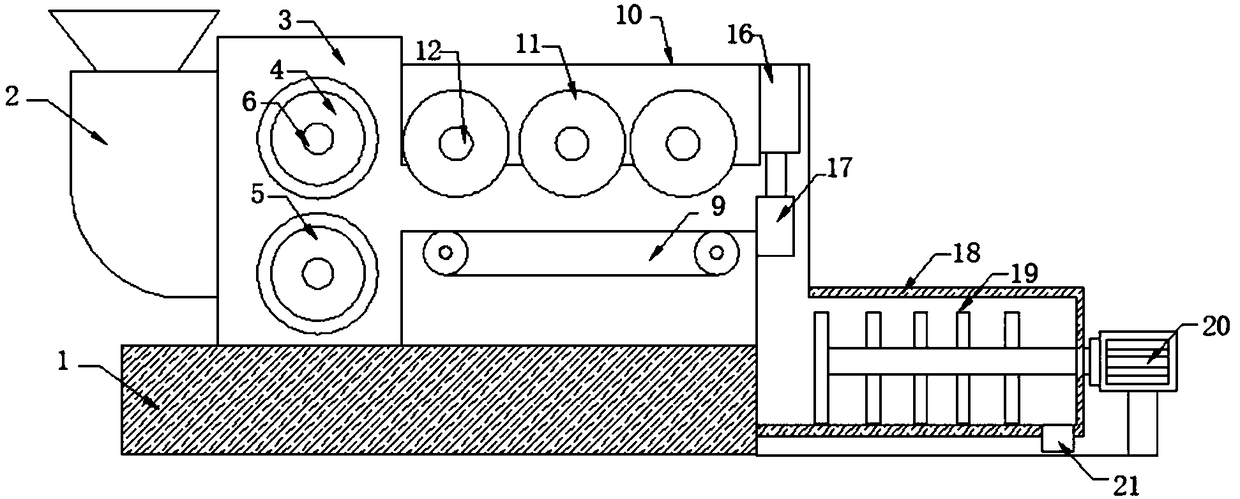

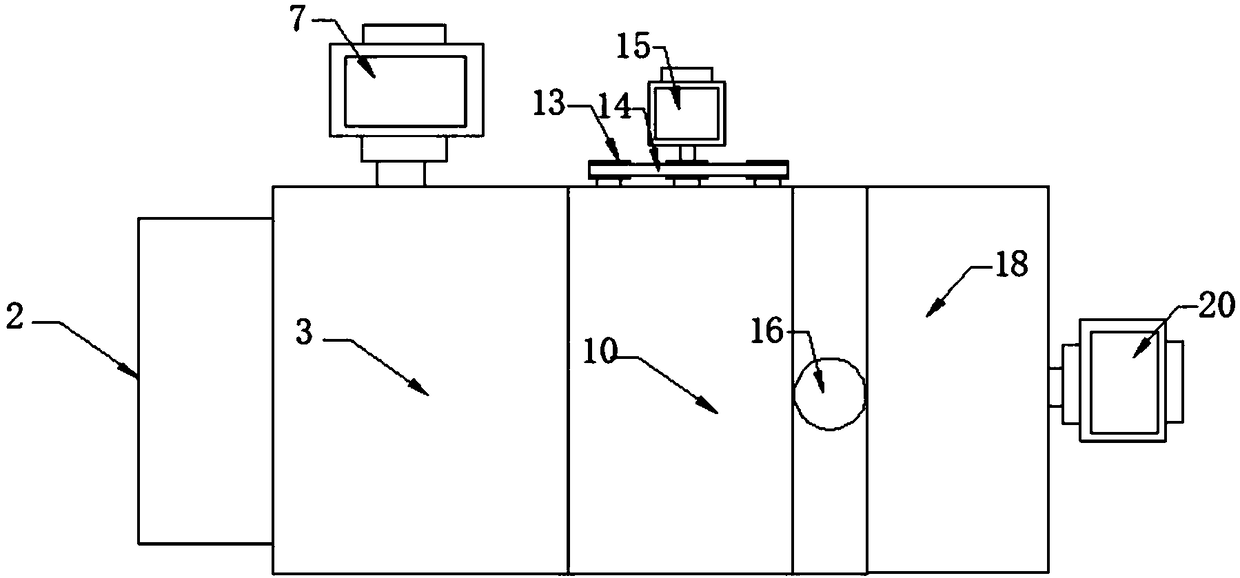

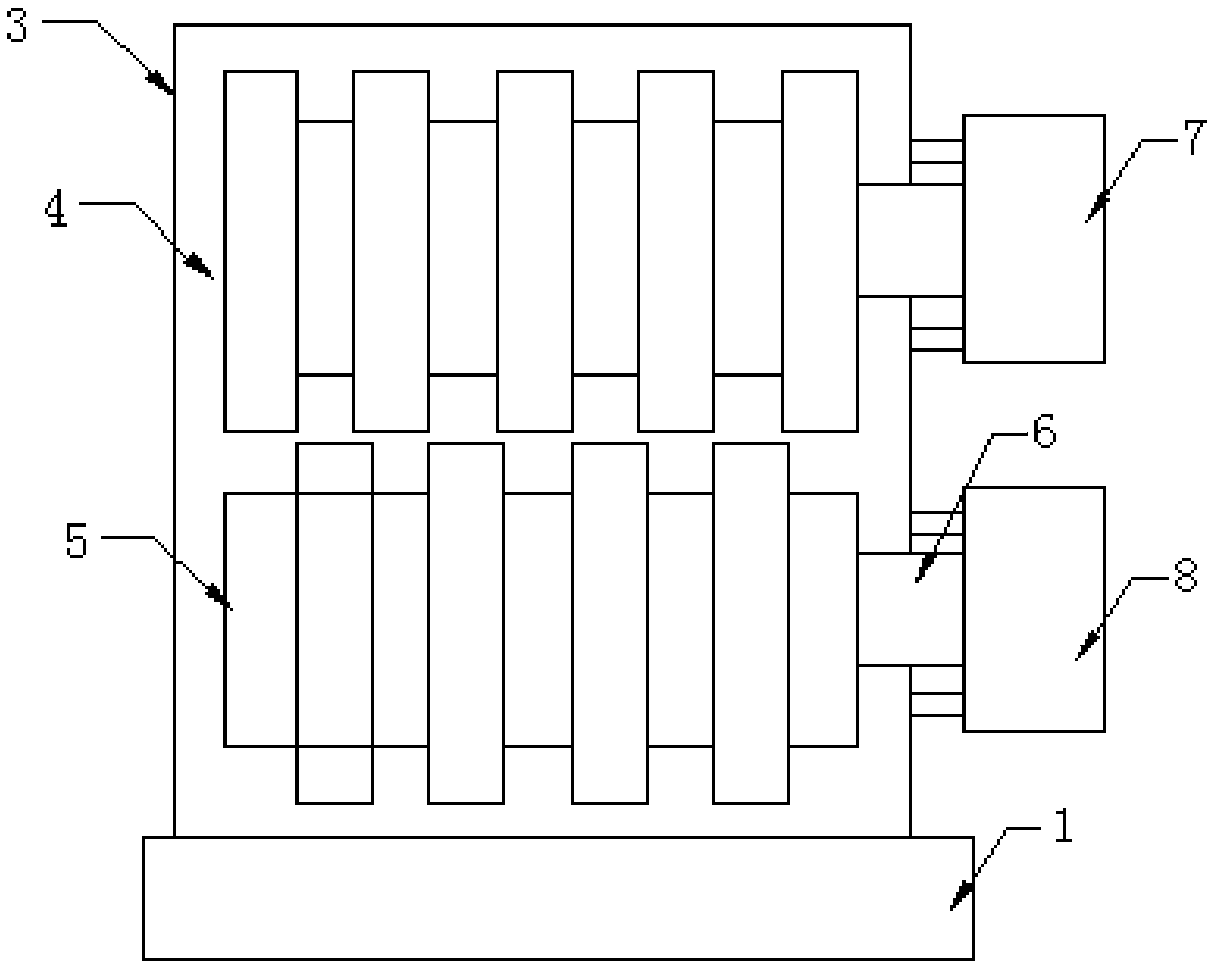

[0016] Example: such as Figure 1-3 As shown, the present invention is a crushing equipment for plastic recycling, including a base 1, one end of the base 1 is fixedly connected with a feed port 2, and the other end of the feed port 2 is fixedly connected with a cutting seat 3, and the inside of the cutting seat 3 The first splitting wheel 4 and the second splitting wheel 5 are fixedly connected up and down in sequence, and the inside of the first splitting wheel 4 and the second splitting wheel 5 are connected with a first rotating shaft 6, and one end of the two first rotating shafts 6 runs through to the cutting machine. The outside of the seat 3 is respectively connected with a first motor 7 and a second motor 8, and the other end of the cutting seat 3 is fixedly connected with a split seat 10, and the interior of the split seat 10 is horizontally provided with three rolling wheels 11, and the three rolling wheels 11 are fixedly connected with three gears 13 on the outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com