Early failure rate change-point recognition method based on monitoring Weibull shape parameter

A technology of early failure rate and shape parameters, applied in the field of quality management, can solve the problems of ignoring the early failure rate change point analysis and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described in detail below with reference to the drawings and examples.

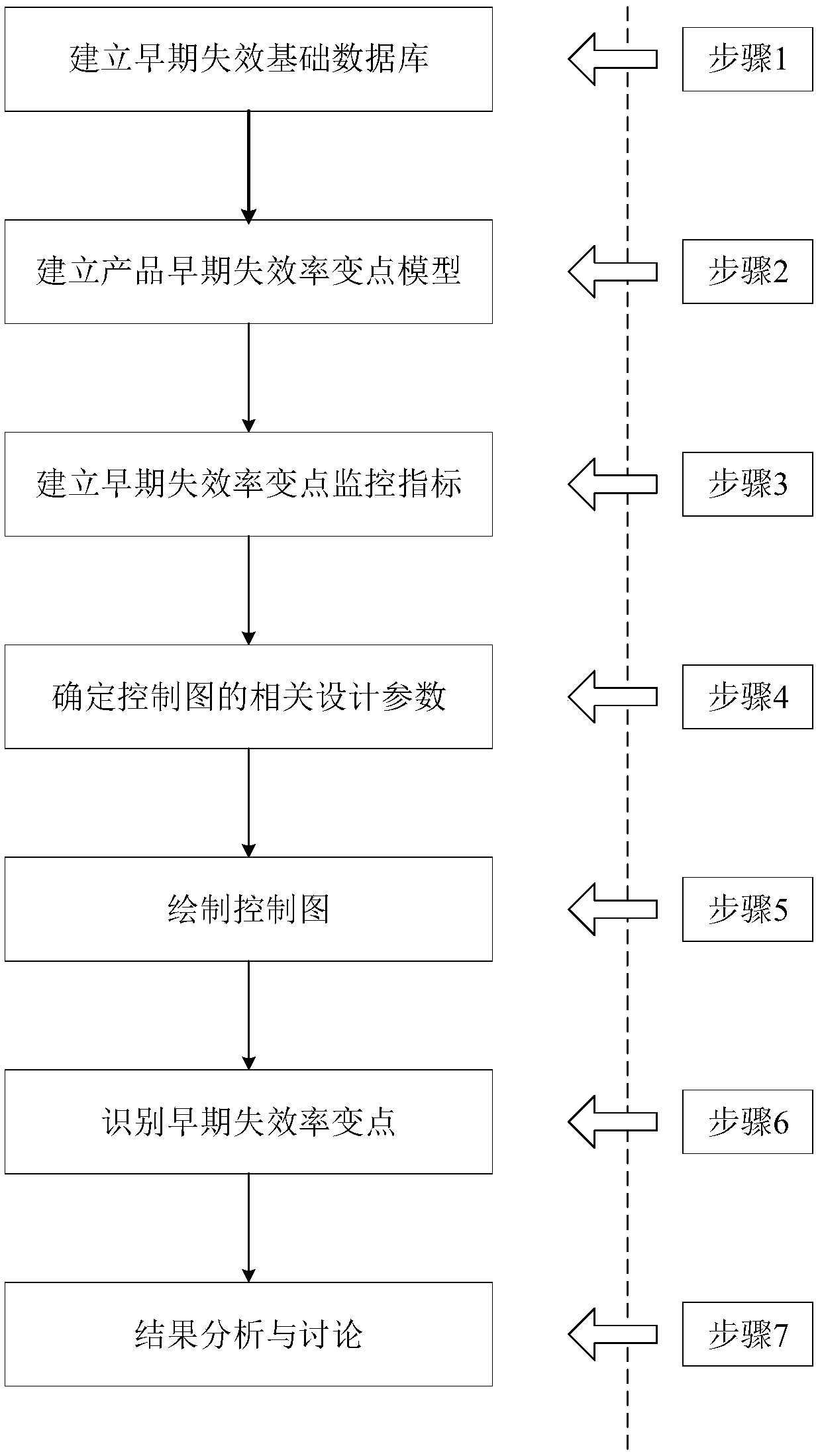

[0072] The present invention is an early failure rate change point identification method based on monitoring Weibull shape parameters. See the specific steps figure 1 As shown, the implementation steps are as follows:

[0073] Step 1 Extract the early life test data of the product from the basic database related to the early failure of the product for subsequent key analysis. In this example, in order to collect the quality information of a certain electromechanical product, a burn-in test is carried out for a certain batch of products that have just been manufactured, and the product life information is recorded. See Table 1 below.

[0074] Table 1. Product life data

[0075]

[0076] Step 2 combines the general failure rules of the product, and establishes the early failure rate change point model for the early stage failure rate with time.

[0077] The product failur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com