Tail end module for modular combined ice chest and ice chest

A modular and cold box technology, which is applied in the direction of household refrigeration devices, applications, coolers, etc., can solve the problems that cannot effectively meet the needs of freezing, quick freezing, rapid precooling, single function of the refrigeration terminal, and low refrigeration energy efficiency ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

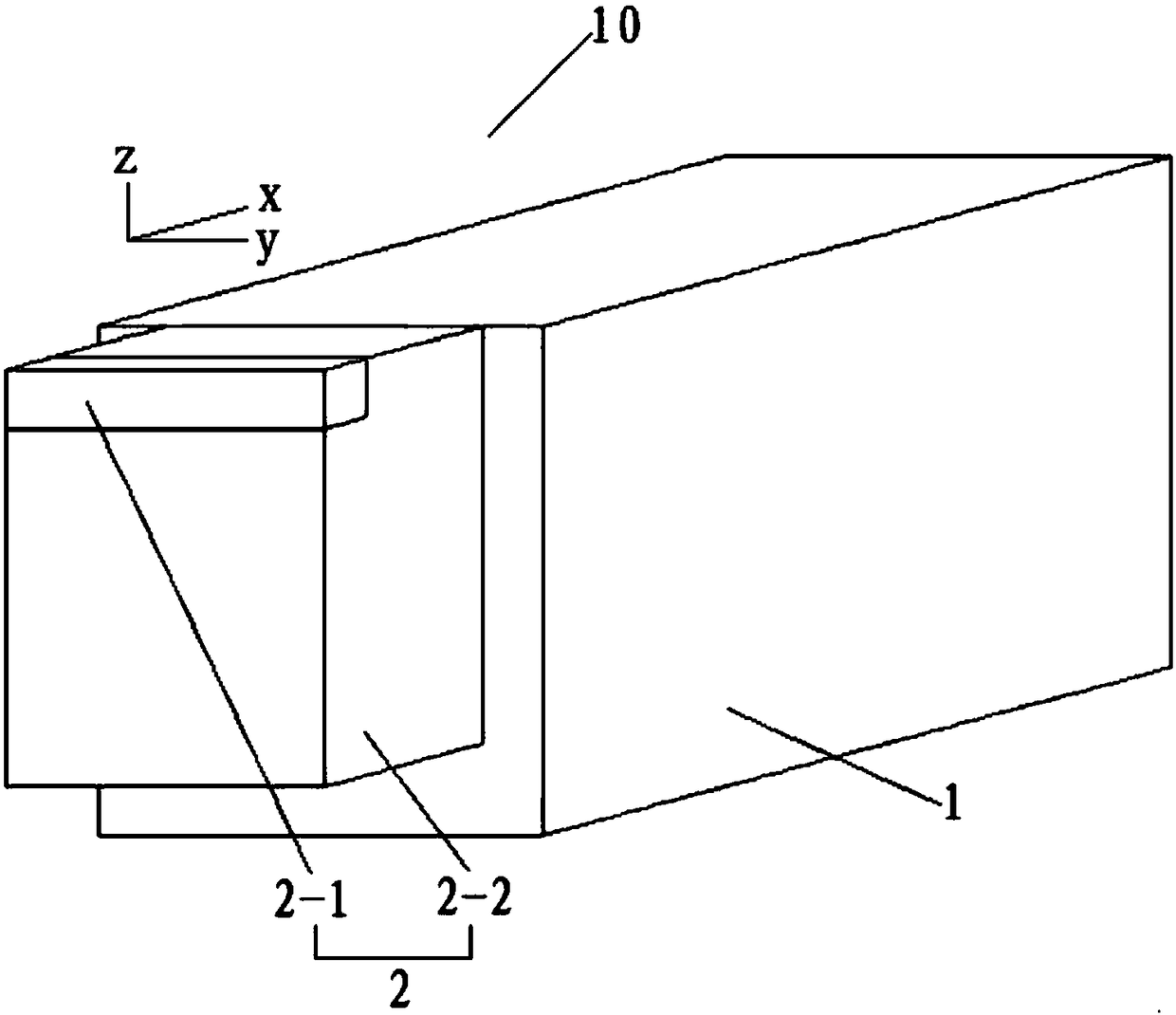

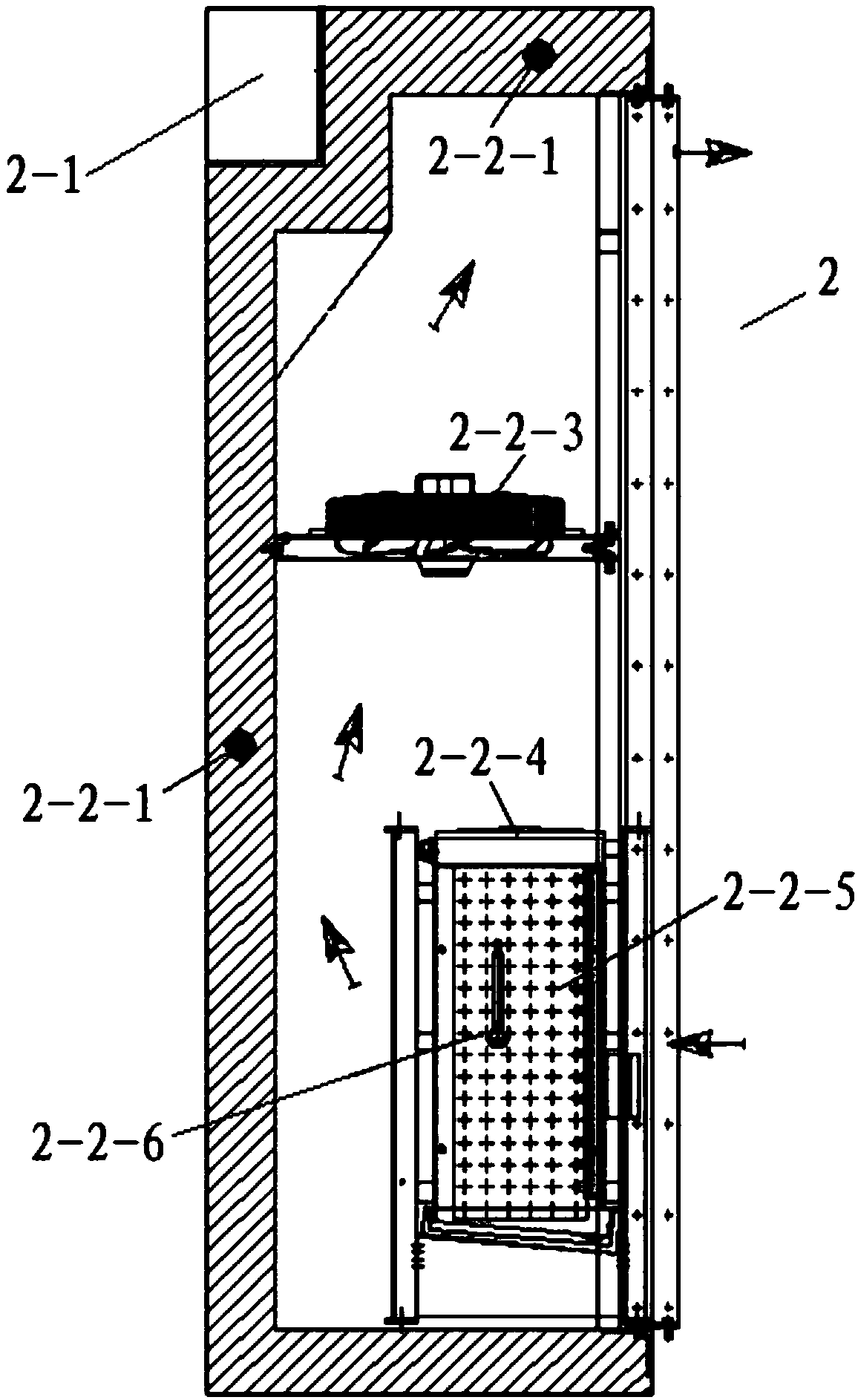

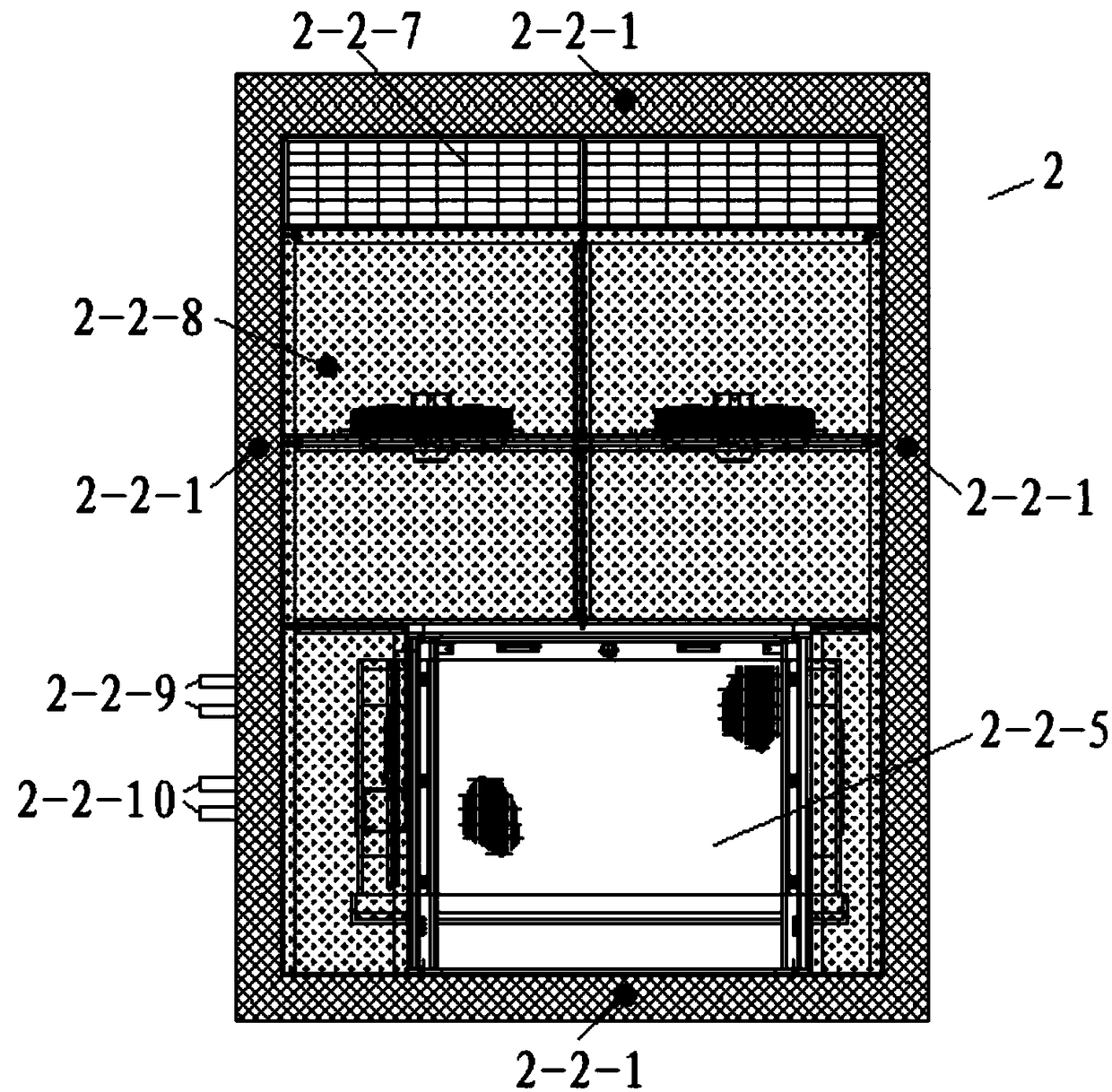

[0032] figure 1 is a specific structural schematic diagram of the cold box, wherein the cold box includes a box body module and an end module, and the end module is arranged on the outer end surface of the box body module; figure 2 For modular combination cold boxes along figure 1 The cross-sectional view of the Y-axis direction, image 3 For modular combination cold boxes along figure 1 The cross-sectional view of the X-axis direction.

[0033] On the one hand, an embodiment of the present invention provides an end module for a modular combined cold box, including:

[0034] The main body of the end module 2-2; wherein, the box module 1 is provided with a refrigeration space for placing goods; the box module 1 can also be replaced by a cold room or cold storage with equivalent functions.

[0035] The terminal module main body 2-2 includes a power distribution and control sub-module 2-1 and a plurality of sub-function modules, and each sub-function module is respectively c...

Embodiment 2

[0060] Compared with Embodiment 1, the difference only lies in:

[0061] Such as Figure 4 to Figure 6 According to the optimization of the above-mentioned technical solution, the housing is embedded in the box module 1 of the modularized cold box, and the housing is used to communicate with the power distribution and control sub-modules. The panel connected to the modules is located outside the box module 1 and is made of heat-insulating material, and the other panels of the housing are made of non-insulating material.

[0062] When the end module is embedded in the box module, the shell of the end module can only adopt a heat-insulating structure on one side, that is, the panel located outside the box module and used to connect with the power distribution and control sub-module is the insulation panel 2-2 -1. The other panels of the shell are made of non-insulation materials. Specifically, in this embodiment, the panel for connecting with the power distribution and control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com