A solar water heater water tank exhaust device

A technology for solar water heaters and exhaust devices, which is applied to solar collectors, solar collector safety, solar thermal energy, etc., can solve problems such as difficult maintenance, single technology, and high cost, and achieve convenient installation, convenient use, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

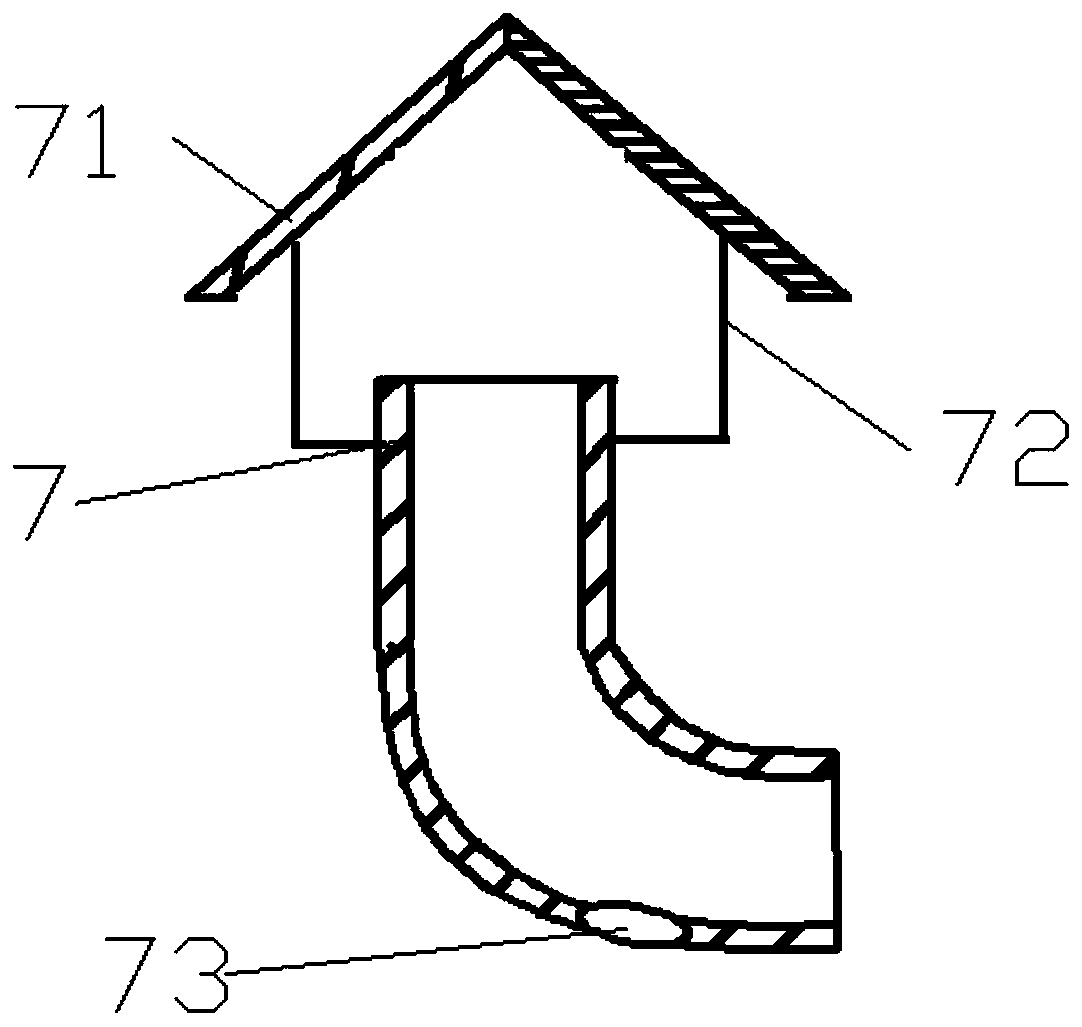

[0028] like figure 1 As shown, a solar water heater water tank exhaust device according to the present invention includes an insulated water tank 1, an exhaust tailpipe 7 is arranged on the outer side of the first side wall 11 of the insulated water tank 1, and the first side wall 11 is open on the top and communicates with the bottom port of the exhaust tail pipe 7. The opening of the first side wall 11 is provided with a seal 6 capable of sealing the first side wall 11. One end of the seal 6 is connected to the bottom port of the exhaust tail pipe 7. The opening of the first side wall 11 is hinged, and rubber is provided on the circumference of the sealing member 6, so that the sealing effect is better.

[0029] The second side wall 12 of the thermal insulation water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com