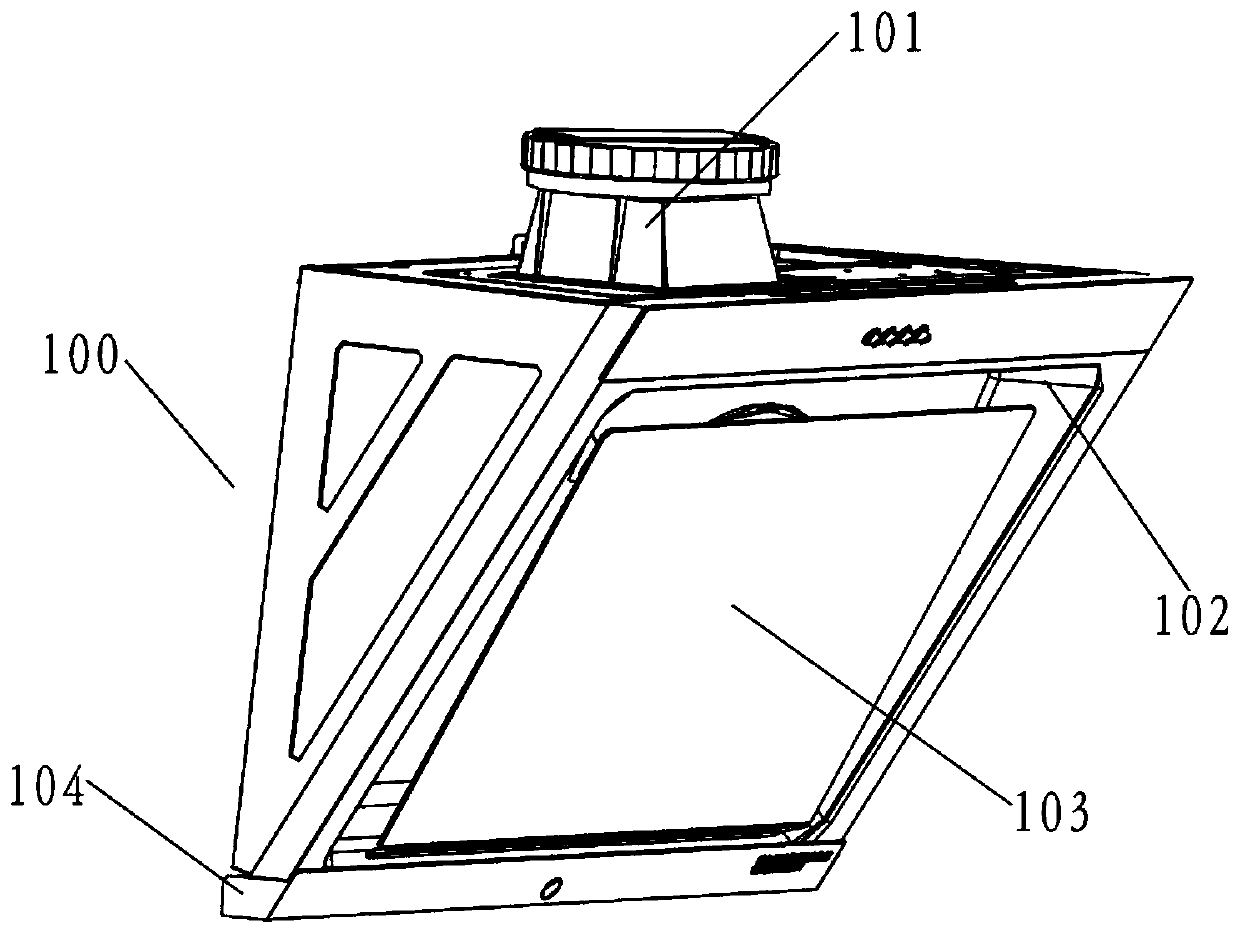

a range hood

A range hood and air intake technology, applied in the field of kitchen appliances, can solve the problems of low air intake efficiency, loss of air volume, poor smoking effect, etc., and achieve the effects of increasing smoke collecting area, large volume and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

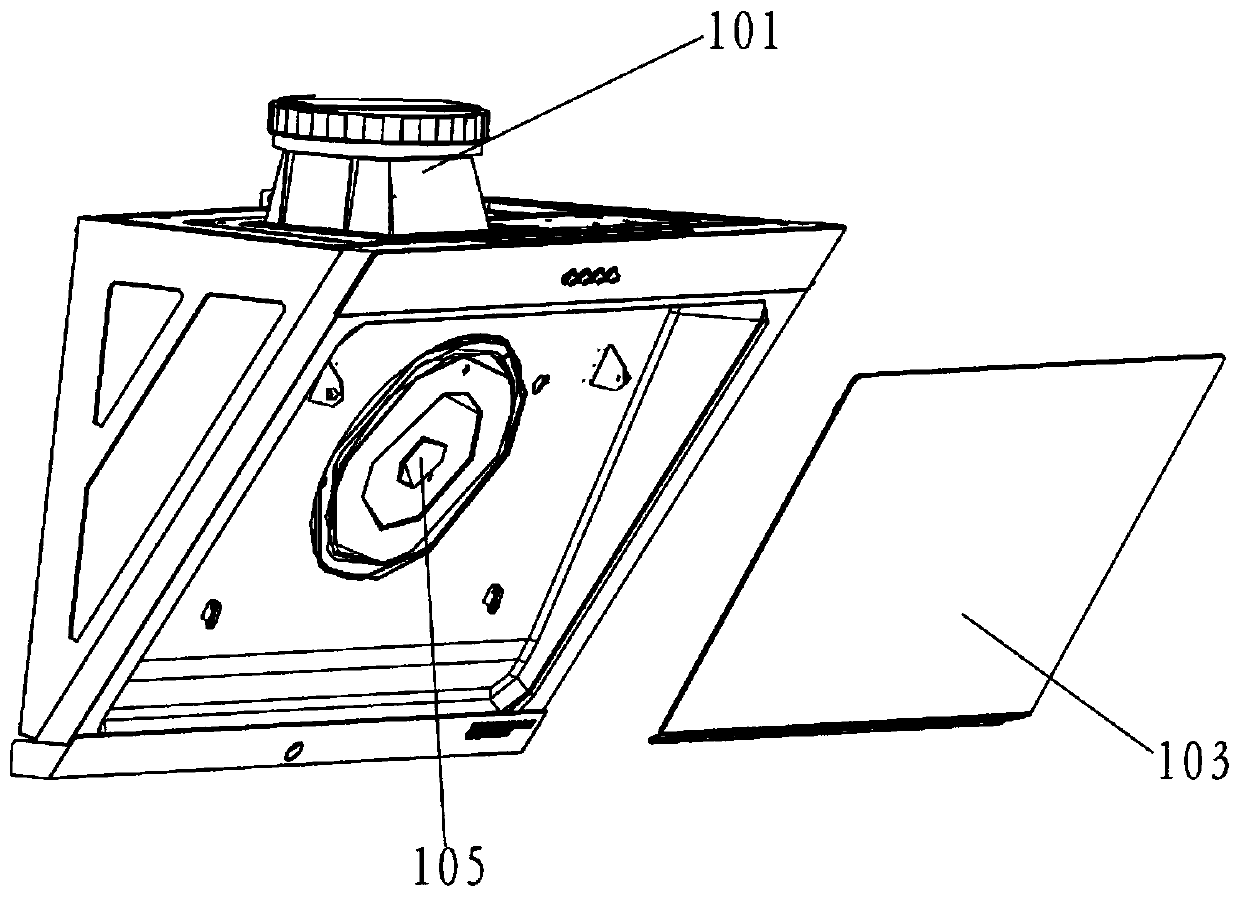

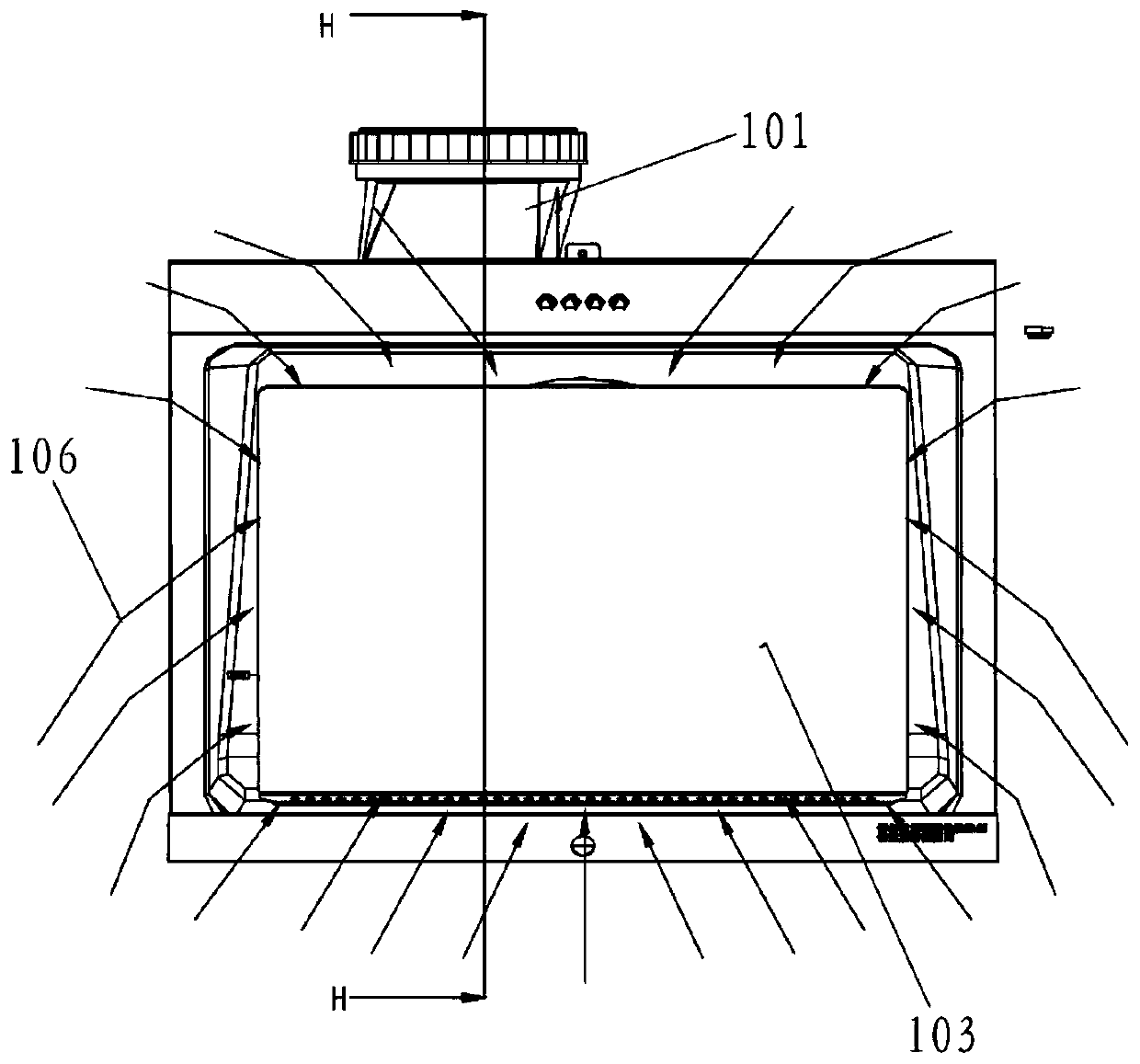

[0052] Such as Figure 5 to Figure 18 As shown, the embodiment of the present invention provides a range hood 200, which includes a box body and an air intake front assembly installed on the box body. The air intake front assembly includes a deflector 221 and at least two air intake nets 241. The left and right sides of the flow plate 221 are respectively provided with a first air inlet cavity 2211 and a second air inlet cavity 2212 protruding toward the direction of the box body. The first air inlet cavity 2211 and the second air inlet cavity 2212 Each is provided with at least one air inlet; the air inlet net 241 is arranged at the air inlet, and the air inlet net 241 is set in one-to-one correspondence with the air inlet.

[0053] The range hood 200 provided by this application adopts double-cavity negative pressure distribution, which has great advantages in collecting smoke and smoking, especially for double-cookers. Specifically, by setting up two air inlet cavities on t...

Embodiment 2

[0087] The difference with the technical solution of Embodiment 1 is:

[0088] Such as Figure 19 to Figure 20 As shown, in this embodiment, the longitudinal section shapes of the first air inlet cavity 2211 and the second air inlet cavity 2212 are both triangular, and one or more of the four cavity surfaces of the first air inlet cavity 2211 One or more of the four cavity surfaces of the first and second air inlet cavity 2212 are provided with air inlets.

[0089] Both the first air inlet cavity 2211 and the second air inlet cavity 2212 on the deflector 221 preferably adopt the structure of a triangular cavity, and the first air inlet cavity 2211 and the second air inlet cavity 2212 are all provided with inlets. tuyere. Wherein, each triangular cavity includes four cavity surfaces, one or more of the four cavity surfaces of the first air inlet cavity 2211 and one of the four cavity surfaces of the second air inlet cavity 2212 Air inlets are provided on one or more of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com