Durable swirl-type air pump

A durable, vortex technology, applied in the field of vortex pumps, can solve the problems of difficult discharge of internal heat, rising coolant temperature, and rising air pump temperature, achieving good working results, enhanced stability, and reduced manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

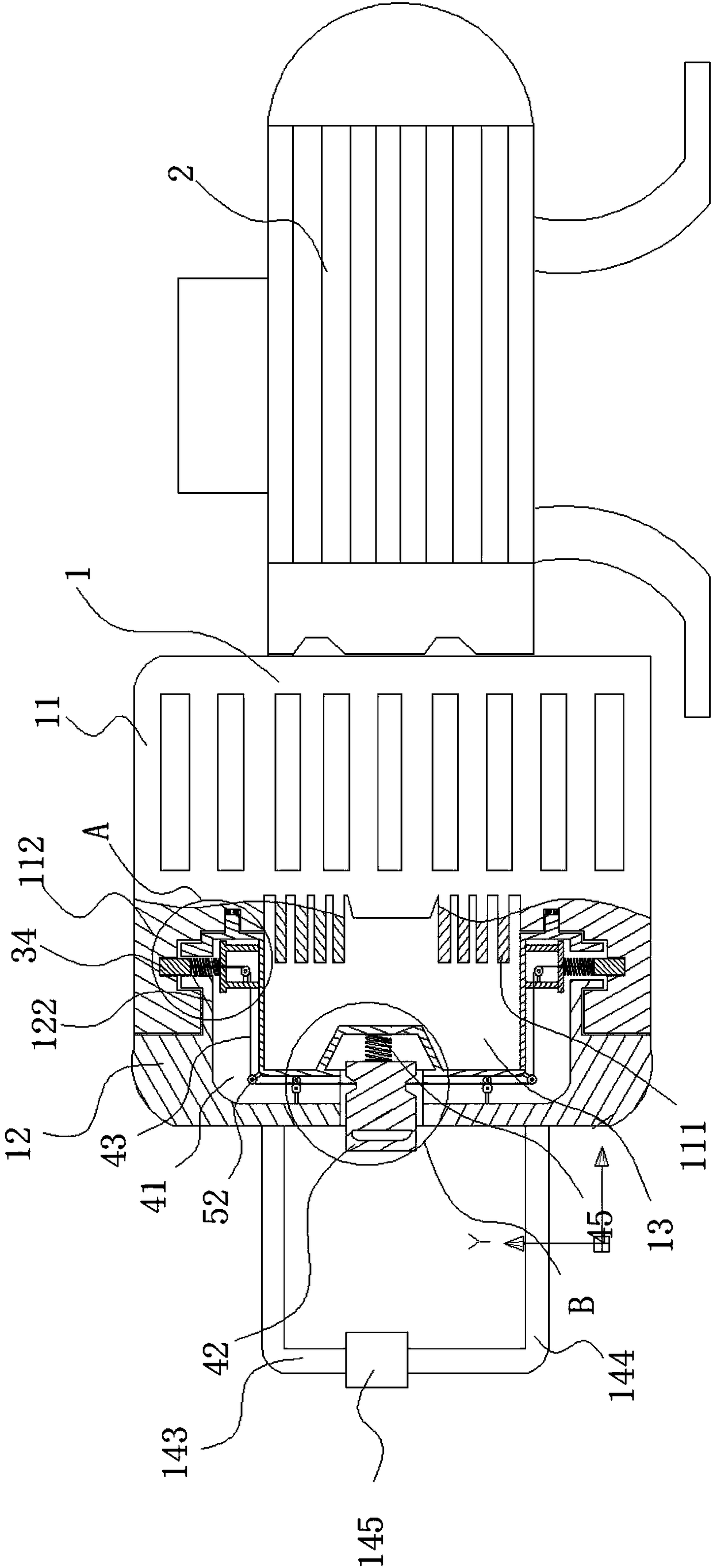

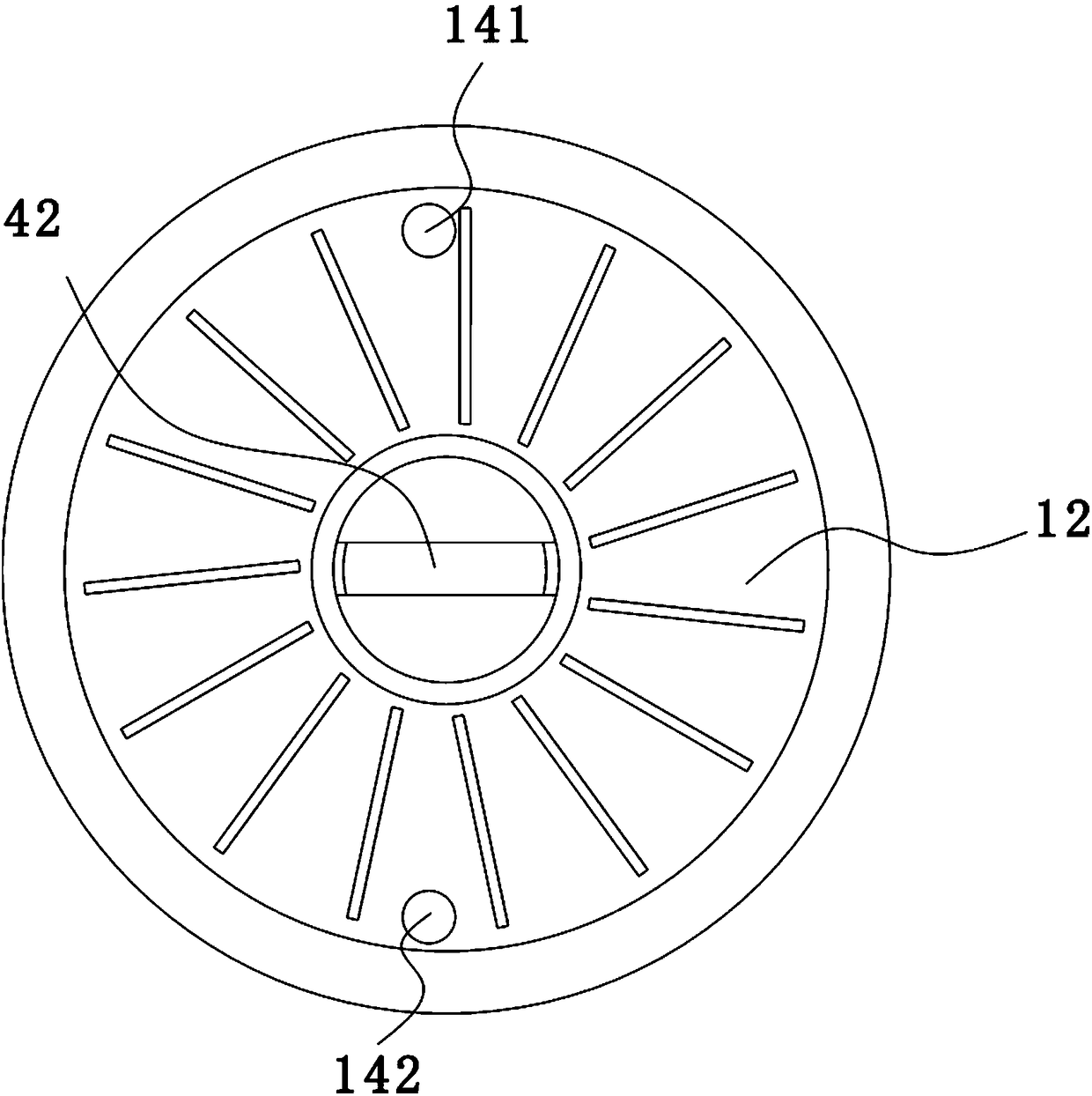

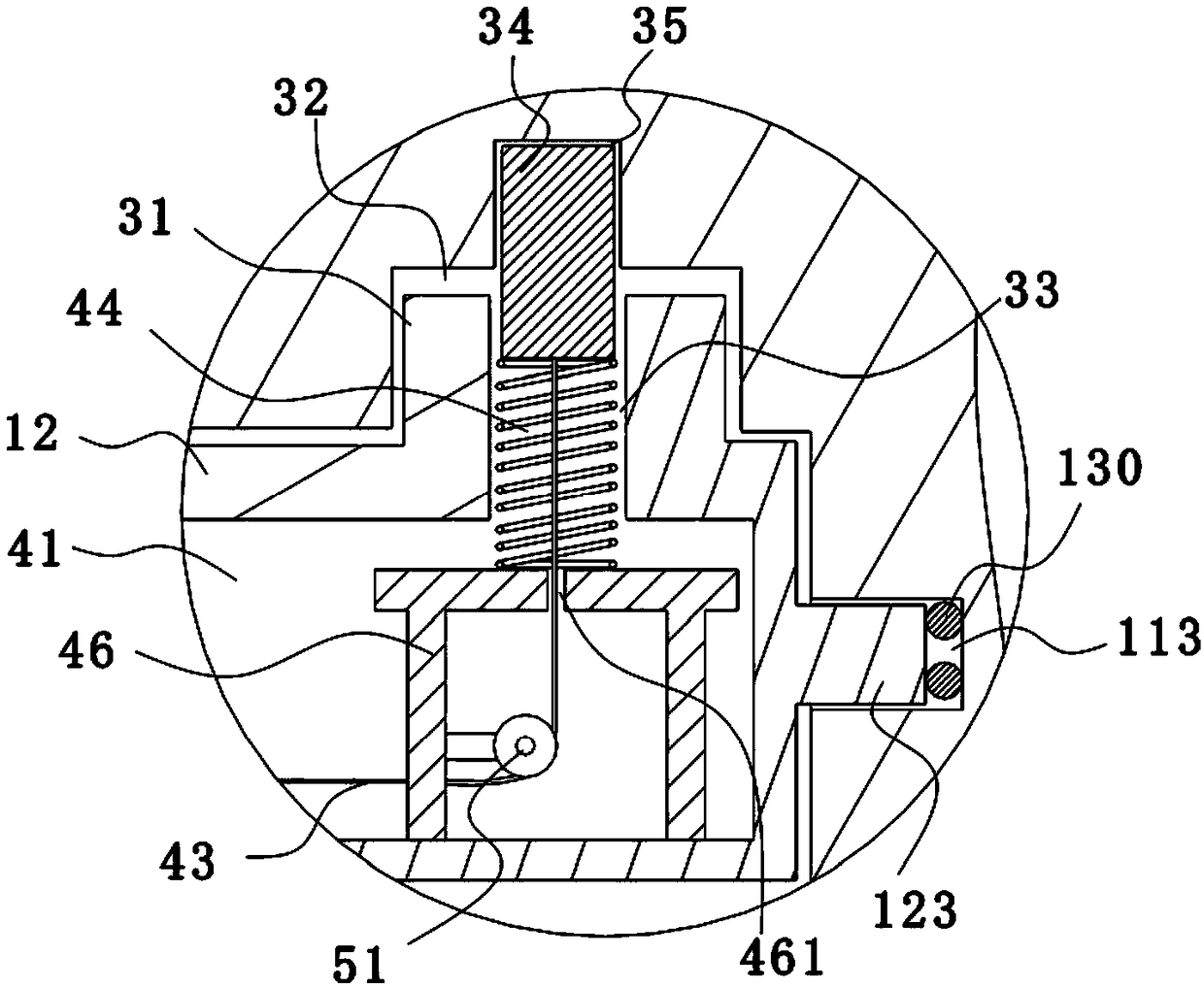

[0020] Such as Figure 1-3 As shown, a durable vortex air pump includes a housing 1, an impeller and a drive member 2; wherein the drive member 2 is a motor, and the impeller is the impeller of an existing vortex air pump on the market, so in This will not be repeated; the housing 1 includes a first housing 11 and a second housing 12, the first housing 11 and the second housing 12 are made of metal, and the impeller is suitable for the first In the housing 11, the output shaft of the drive member 2 penetrates into the first housing 11, and then connects with the impeller. The specific connection is the prior art, and will not be repeated here; further, the The first casing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com