Sub-clamp device for clamping M-shaped packaging bag

A packaging bag and clamping technology, applied in the field of sub-clamp devices, can solve the problems of insufficient packaging, environmental pollution, packaging filling, etc., and achieve the effect of improving the packaging quality and packaging speed of materials, optimizing the packaging environment, and ensuring the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

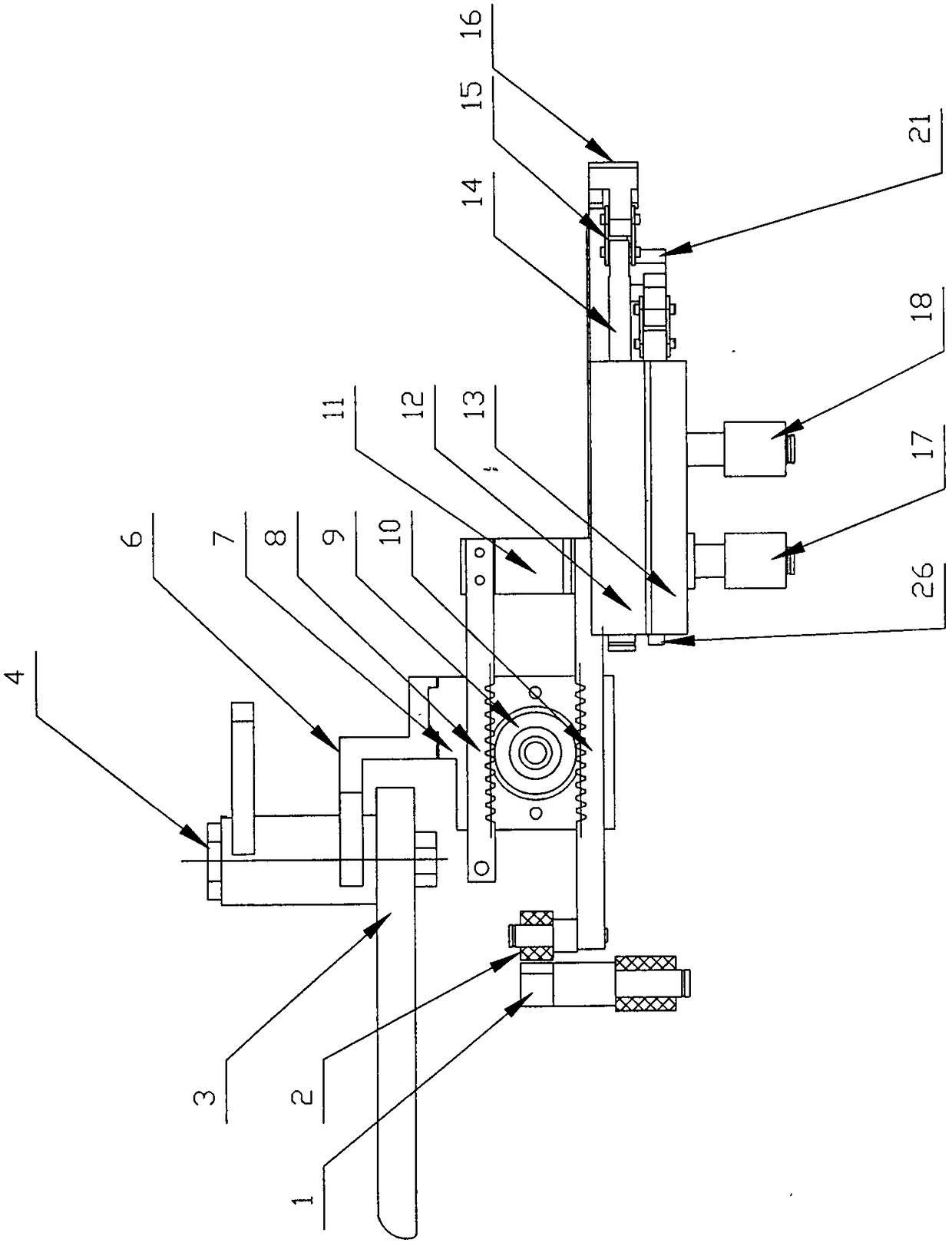

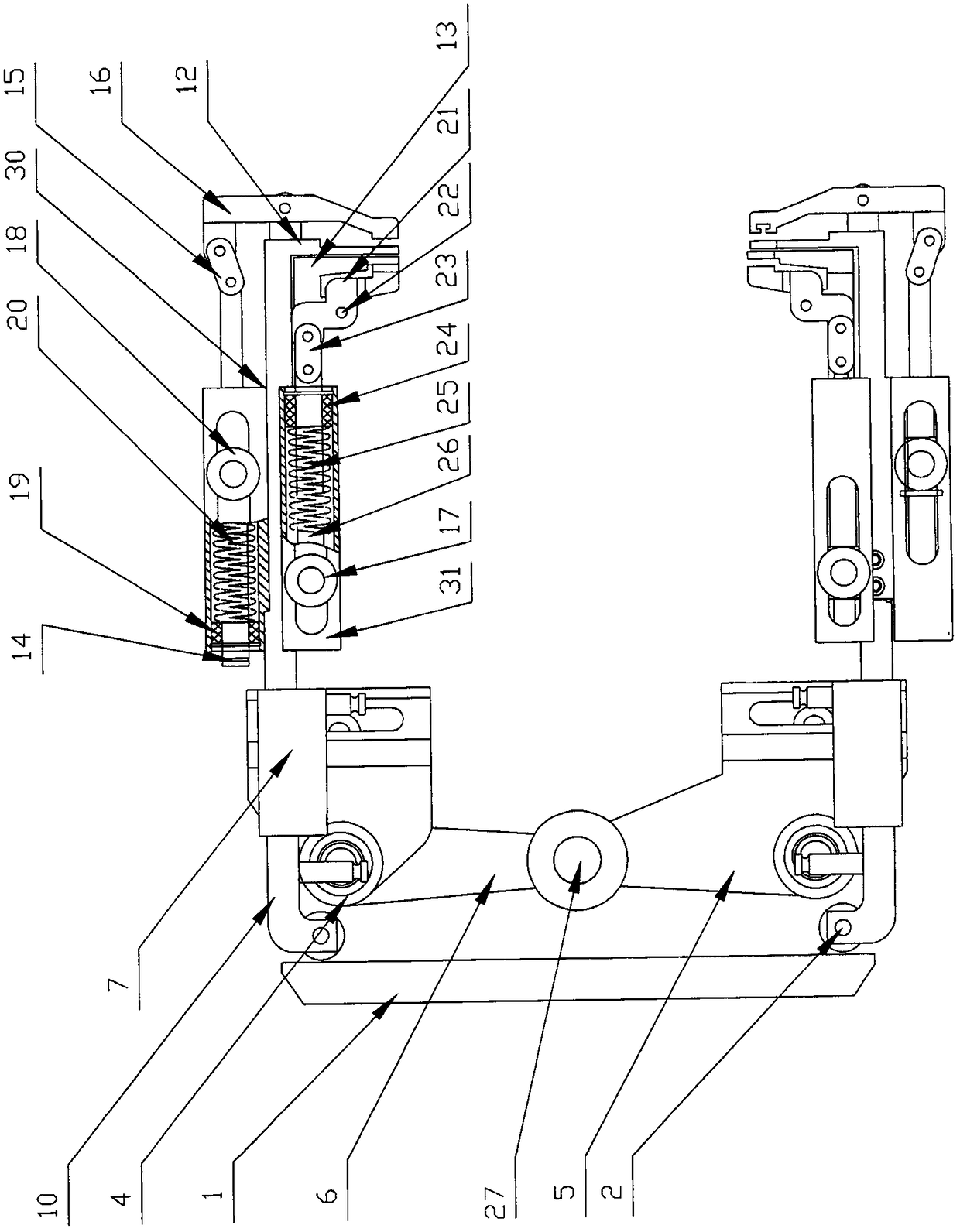

[0010] refer to figure 1 , figure 2 It can be seen that the sub-clamp device for clamping the M-shaped packaging bag of the present invention includes a left sub-clamp seat 6 and a right sub-clamp seat 5, and a gear seat 7 is equipped on the left sub-clamp seat 6 and the right sub-clamp seat 5, so that An upper rack 8, a gear 9, and a lower rack 10 interconnected are provided on the gear seat 7, an outer clamping mechanism 30 is installed on the upper rack 8 (through the connecting block 11), and an inner clamping mechanism 30 is installed on the lower rack 10. Mechanism 31, described lower rack 10 (by respective unclamping roller 2) links to each other with unclamping push plate 1 (being one piece). This unclip push plate 1 links to each other with the bag opening device of packaging machine.

[0011] Wherein, the left sub-clamp seat 6 and the right sub-clamp seat 5 (one piece each) are connected through the sub-clamp seat joint 27 . The left sub-clamp seat 6 and the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com