Wheel type robot chassis

A wheeled robot and chassis technology, which is applied in the direction of instruments, motor vehicles, vehicle springs, etc., can solve the problems of difficult to achieve precise control, inability to realize in-situ steering, lack of flexibility, etc., and achieve the effect of strong obstacle surmounting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

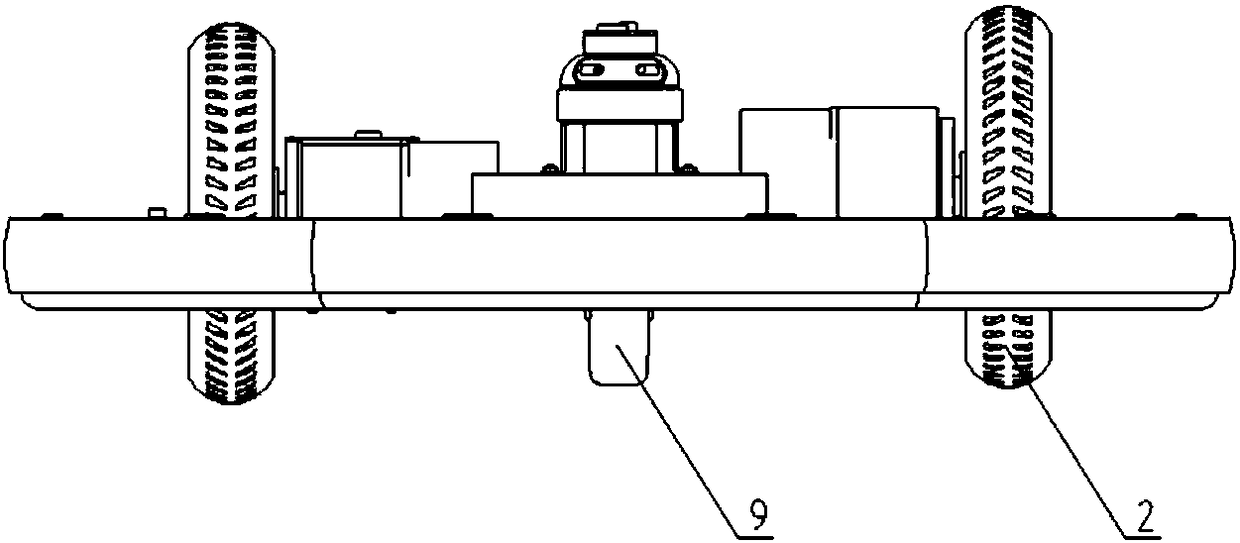

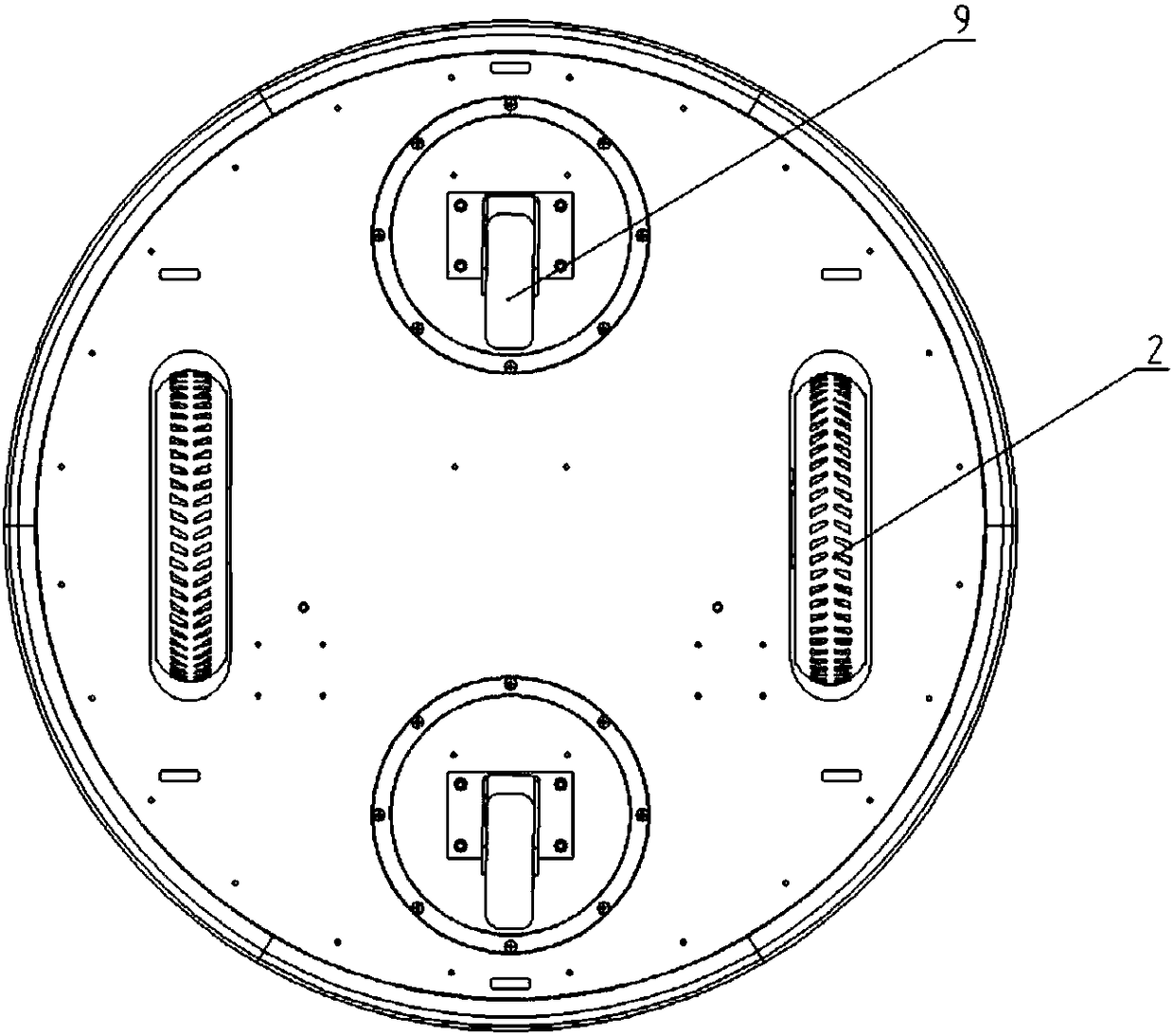

[0036] Embodiment one, such as figure 1 , figure 2 As shown, the wheeled robot chassis disclosed in this embodiment includes a circular base plate 1, a driving wheel 2, a universal wheel mounting seat 3, an elastic suspension device 4, a collision detection device 5, a chassis controller 6, and a laser radar 7 , infrared ranging sensor 8, universal wheel 9.

[0037] combine Figure 1 to Figure 4 It can be seen that two universal wheels 9, front and rear, and two driving wheels 2, left and right, are connected to the circular bottom plate 1, and the two universal wheels 9 and the two driving wheels 2 are arranged in a rhombus shape.

[0038] from figure 1 It can be seen that the universal wheel mounting seat 3, the elastic suspension device 4, the chassis controller 6 and the infrared ranging sensor 8 are all installed on the upper side of the circular base plate 1, and the laser radar 7 is installed on the front universal wheel through a bracket. Seat 3. The chassis cont...

Embodiment 2

[0052] Embodiment 2. The difference between this embodiment and Embodiment 1 is that the elastic suspension device is different, and other structures are the same as Embodiment 1.

[0053] The elastic suspension device of this embodiment adopts Figure 15 to Figure 18 Structure.

[0054] Figure 15 to Figure 18 The elastic suspension shown with the Figure 7 to Figure 10 The difference of the shown elastic suspension device is that the self-adaptive elastic adjustment member adopts extension spring LH. Thus the corresponding structural changes are mainly the layout and installation of the extension springs.

[0055] From Figure 15 to Figure 18 It can be seen that the extension spring LH is arranged parallel to the driving wheel 2 along the front-rear direction, the extension spring mounting seat LHZ at one end is connected to the upper side of the two bracket plates 43 , and the other extension spring mounting seat LHZ is connected to the installation base plate 41 . One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com