Waterproof GRC shower tray production line and production method thereof

A waterproof, production line technology, applied in the direction of ceramic molding machines, ceramic molding workshops, auxiliary molding equipment, etc., can solve the problems of inability to achieve mass production, large labor demand for workers, and slow speed of manual laying bricks, etc., to achieve the solidification time Accurate and rapid, reduce manpower, reduce the effect of worker labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical features of the present invention will be described in further detail below in conjunction with the accompanying drawings so that those skilled in the art can understand.

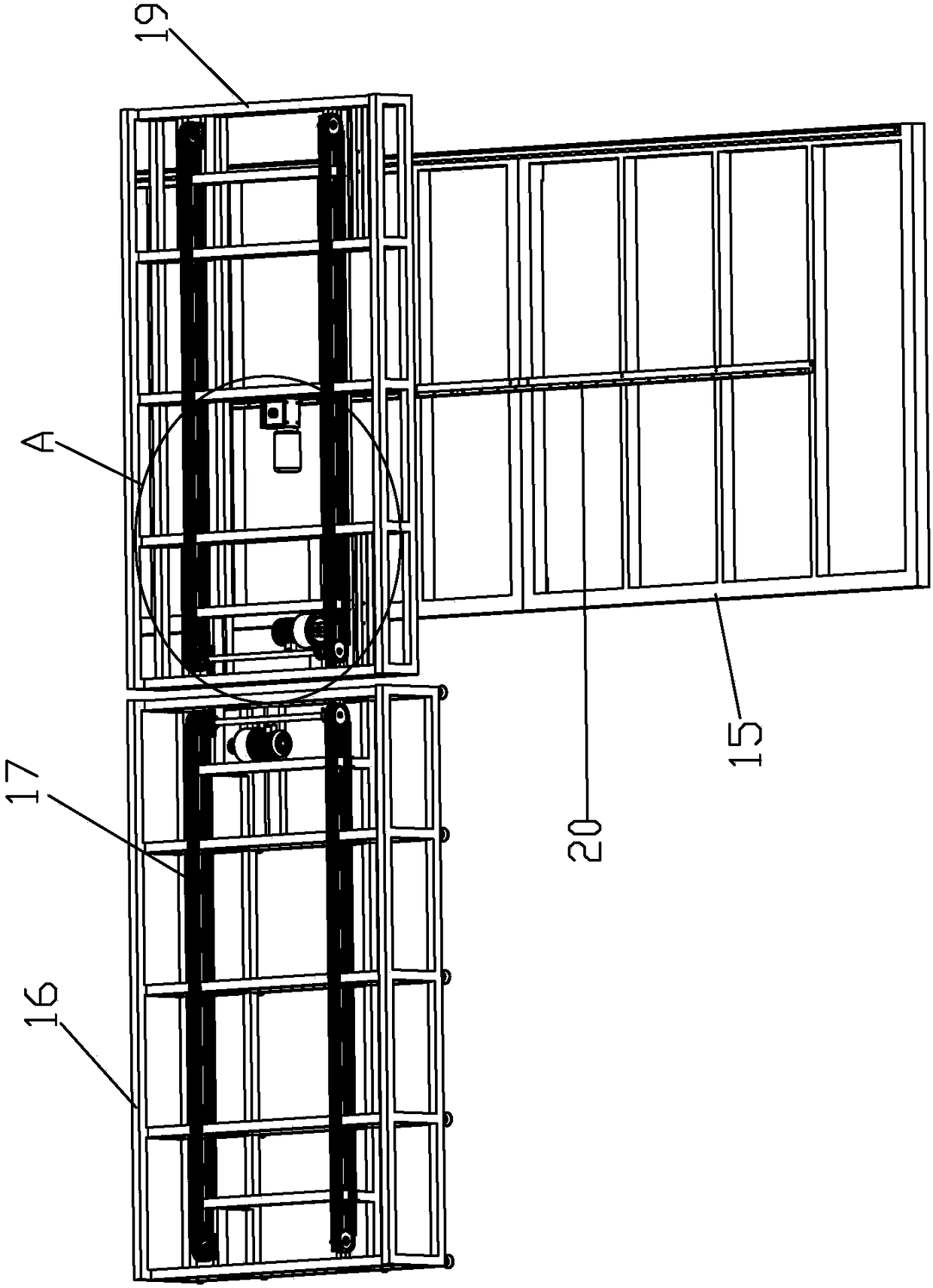

[0052] A waterproof GRC bottom basin production line, such as Figure 1 to Figure 7 Shown, comprise automatic conveying line, be provided with loading and unloading station 100 on the automatic conveying line, be provided with internal circulation station 200 and the temperature that is connected with the output end of internal circulation station 200 at the output end of loading and unloading station 100 Box solidification station 300, the internal circulation station 200 includes the swinging brick station 3, the spraying station 4, the plugging station 6, and the blasting station 7, which are connected successively. Linked to each other with the spraying station 4, a brick laying robot 13 is provided on the brick laying station 3, a spraying robot 14 is provided on the spraying stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com