Hot riveting paper transferring device with positioning structure

A technology of transfer device and positioning structure, applied in metal processing and other directions, can solve the problems of applicability and practicability limitations, affecting binding effect and efficiency, easy to spread or misplaced paper, etc., to achieve strong practicability and good use stability. , Reasonable effect of structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

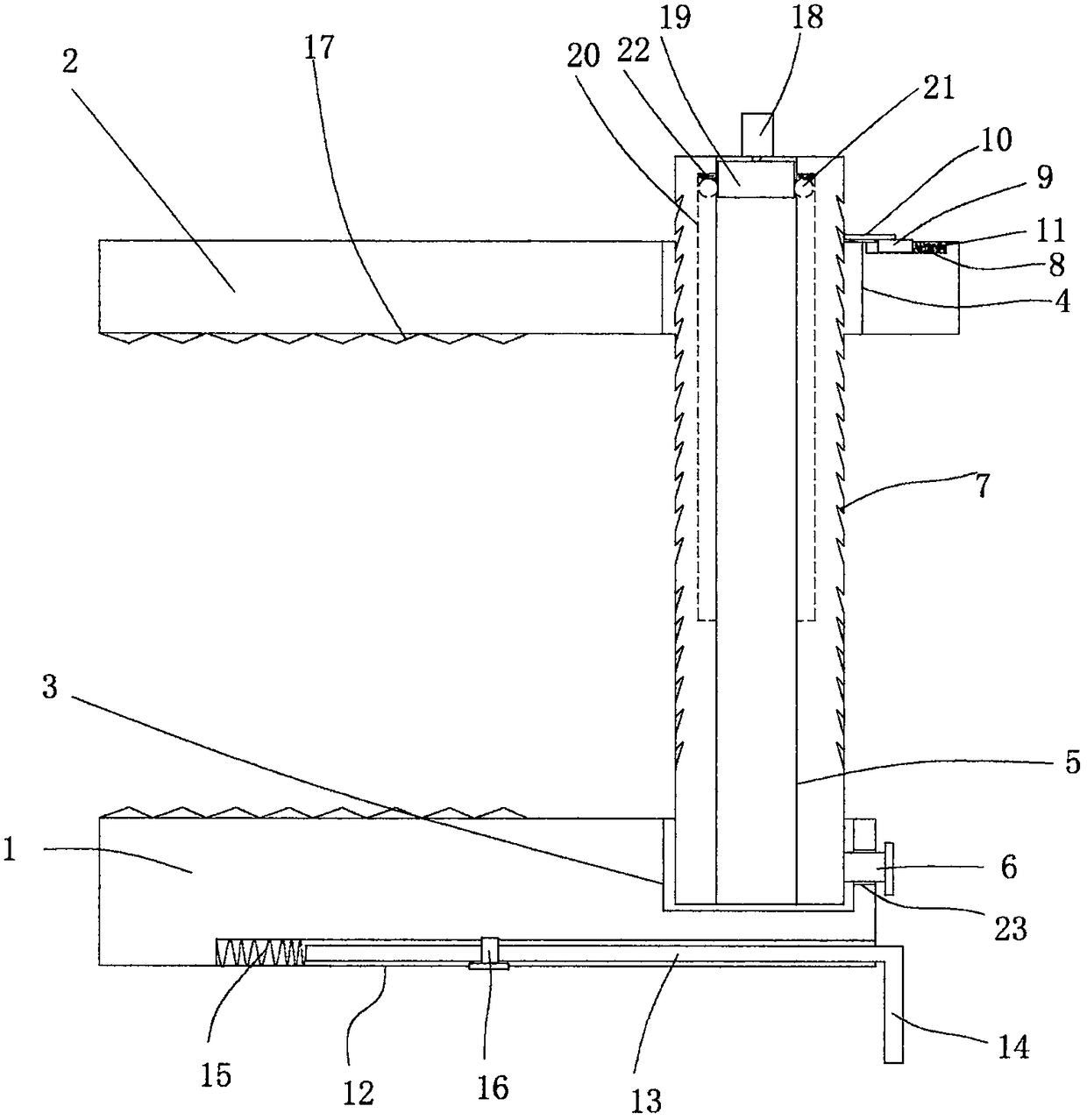

[0015] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0016] See figure 1 , a heat riveting paper transfer device with a positioning structure, comprising a bearing base 1, a pressing panel 2 is arranged on the top surface of the bearing base 1, and a card cavity 3 with an opening on the top surface is arranged in the bearing base 1 , the pressing panel 2 is provided with an up and down transparent I-shaped hole 4, an I-shaped insert rod 5 is arranged in the said I-shaped hole 4, and a Cavity 3 is connected with locking hole 23, and locking pin rod 6 is arranged in described locking hole 23, and the bottom end of described I-shaped insertion rod 5 stretches in described card cavity 3 and passes through locking pin rod. 6 is locked and fixed, an inverted V-shaped card slot 7 is uniformly arranged on the I-shaped insert rod 5, an adjustment groove 8 is arranged on the pressing panel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com