Fan-blade-shaped welding device

A welding device and a fan-blade technology, applied in the field of welding devices and fan-blade welding devices, can solve problems such as automatic positioning and clamping, inability to integrate automatic welding devices and welding production lines, and waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

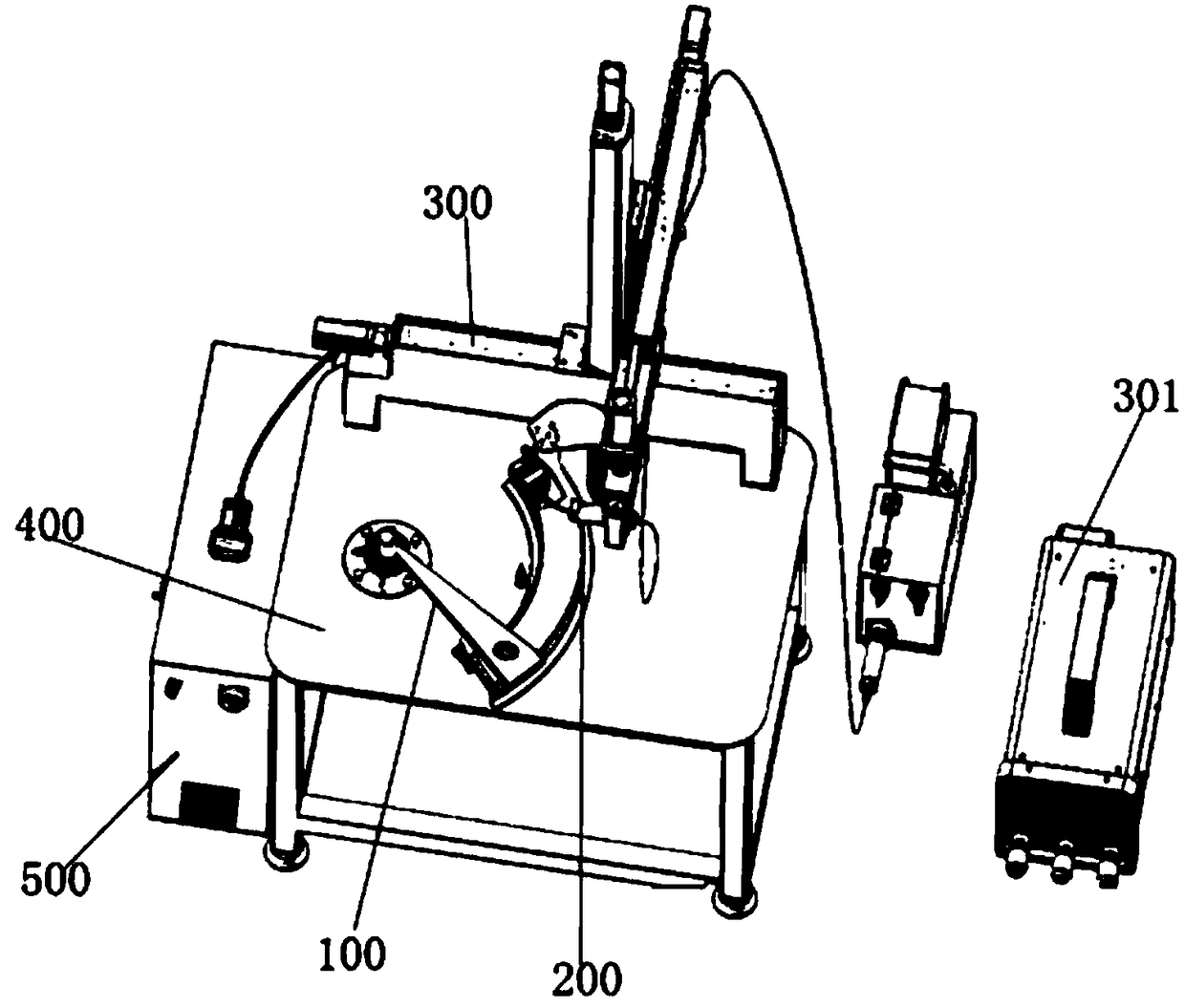

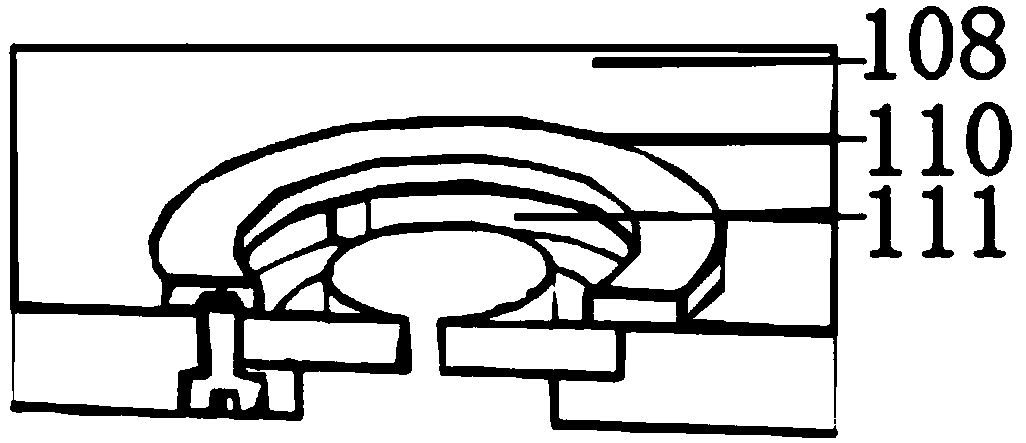

[0024] Figure 1 to Figure 5 A schematic structural diagram of the overall composition and each device of the present invention is shown. like Figure 1 to Figure 5As shown, the present invention provides a fan-shaped welding device. It includes a workbench 400, an electrical cabinet 500, a feeding device 100, a feeding device 200, and a welding device 300. The workbench 400 is provided with a feeding device 100, a feeding device 200, and a welding device 300. The side of the workbench 400 is equipped with an electrical cabinet 500. A control panel is arranged on the electrical cabinet 500, and a main power supply, a control board and a servo driver are arranged in the electrical cabinet 500, and the main power supply, the control panel and the servo driver are respectively electrically connected to the control board t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com