Multi-vacuum-chamber electronic beam welding equipment

An electron beam welding and multi-vacuum chamber technology, applied in electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large repeated investment in equipment, difficulty in taking into account the size of vacuum chamber and welding efficiency, and improve welding utilization. The effect of improving efficiency and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is attached with the manual Figure 1-5 The present invention is further described in detail.

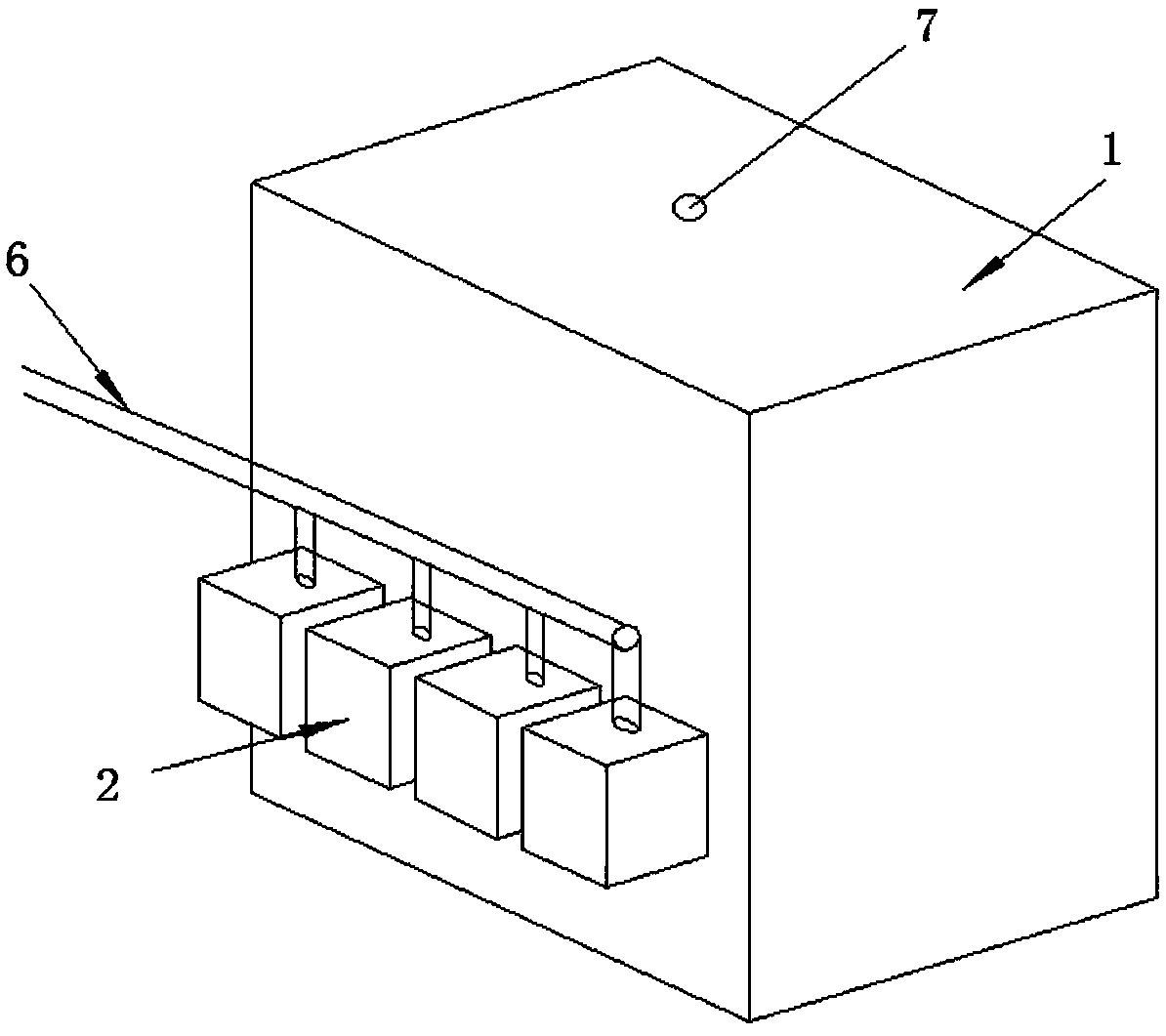

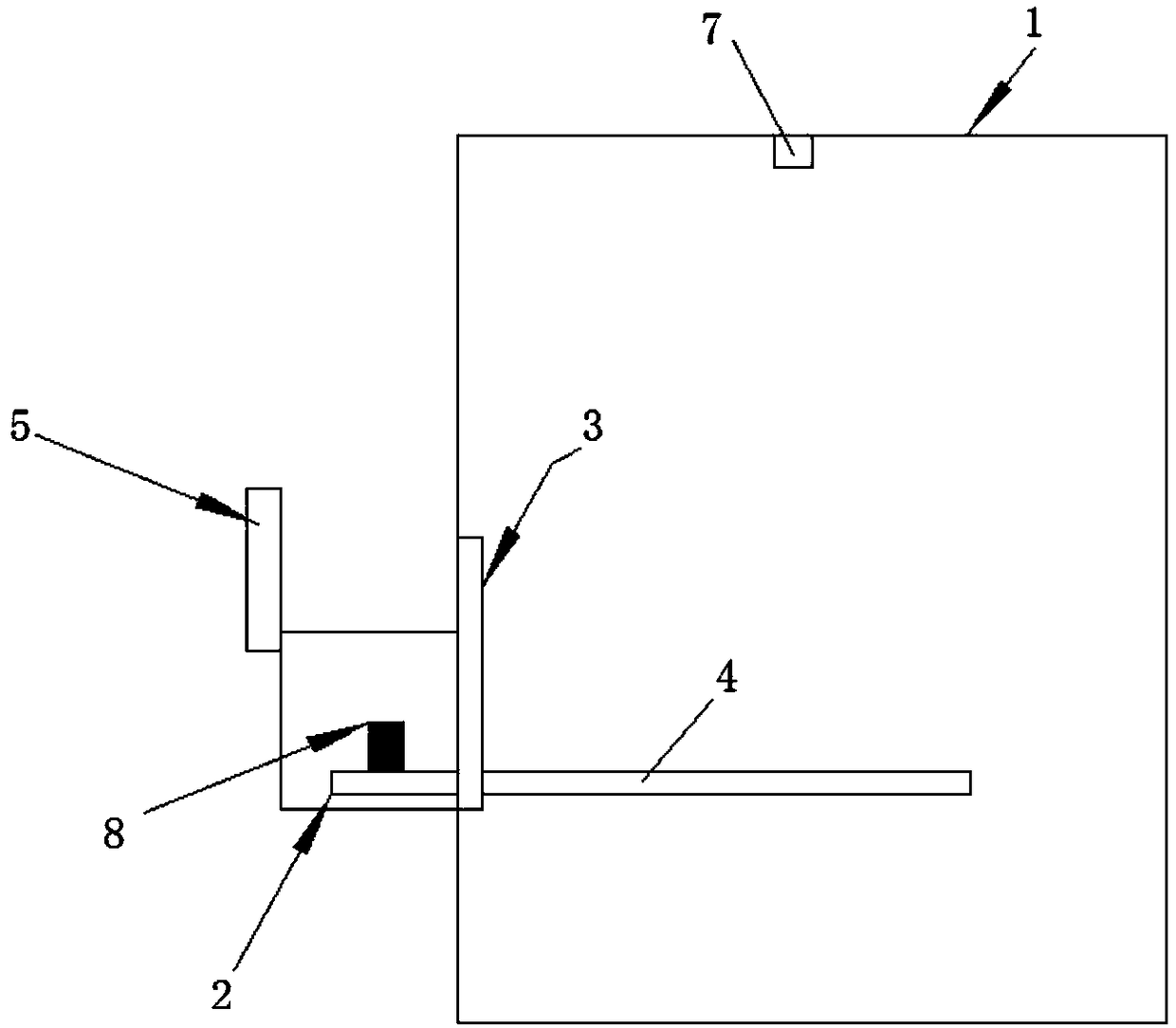

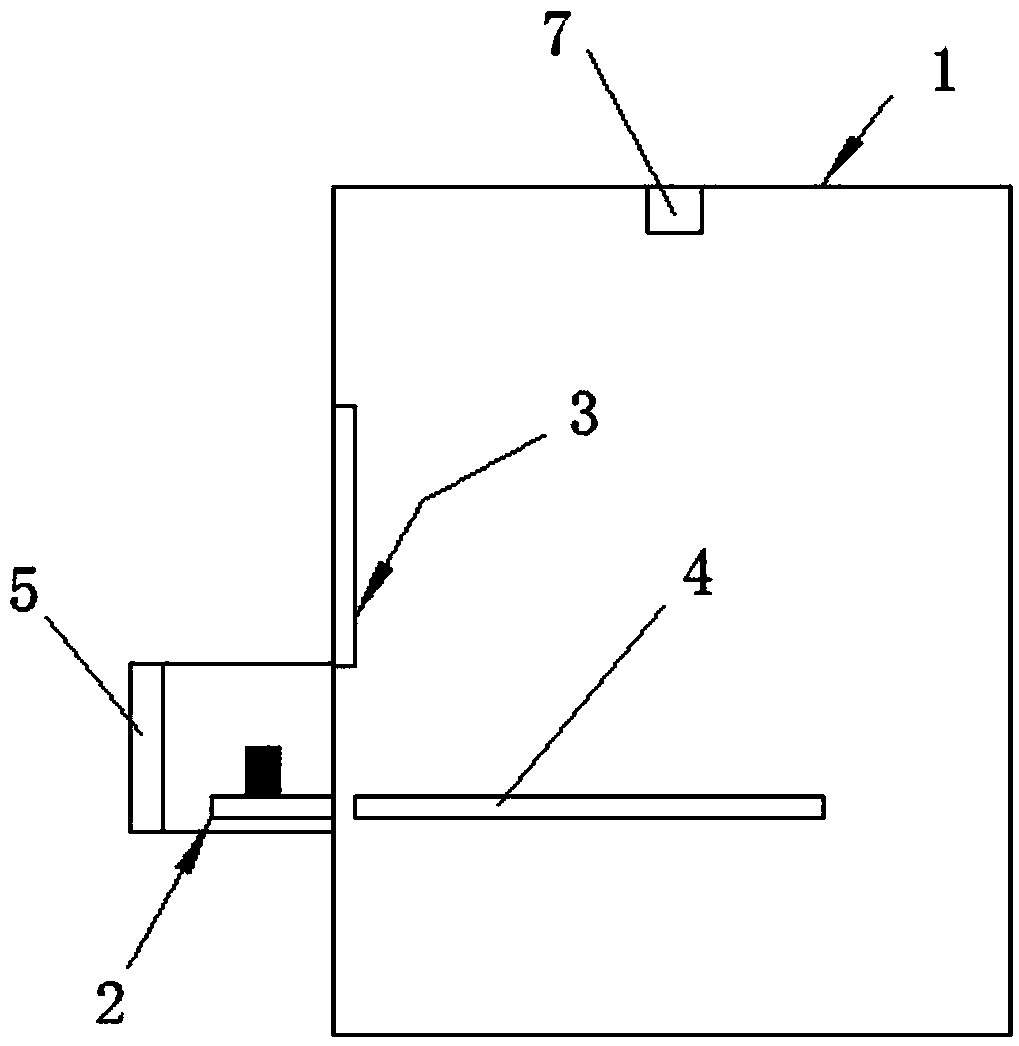

[0019] A multi-vacuum chamber electron beam welding equipment, comprising a main vacuum chamber 1 and a plurality of auxiliary vacuum chambers 2;

[0020] A plurality of sub-vacuum chambers 2 are welded on the outer wall of the main vacuum chamber 1; the sub-vacuum chambers 2 are connected through the main vacuum chamber 1 and separated by a sealed partition 3; the sub-vacuum chambers 2 and the main vacuum chamber 1 are connected with a mechanical transmission tray 4;

[0021] The auxiliary vacuum chamber 2 is provided with a vacuum hatch 5, and the upper part is provided with an auxiliary vacuum system 6;

[0022] The top of the main vacuum chamber is provided with an electron gun 7, the electron gun can slide back and forth in the vacuum chamber, and the main vacuum chamber

[0023] Also connected to the main vacuum system.

[0024] The use of welding equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com