Injector assembly with thermal protection sleeve

A technology for thermal protection and injectors, applied to fuel injection devices, engine components, machines/engines, etc., can solve problems such as damage to liquid injectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

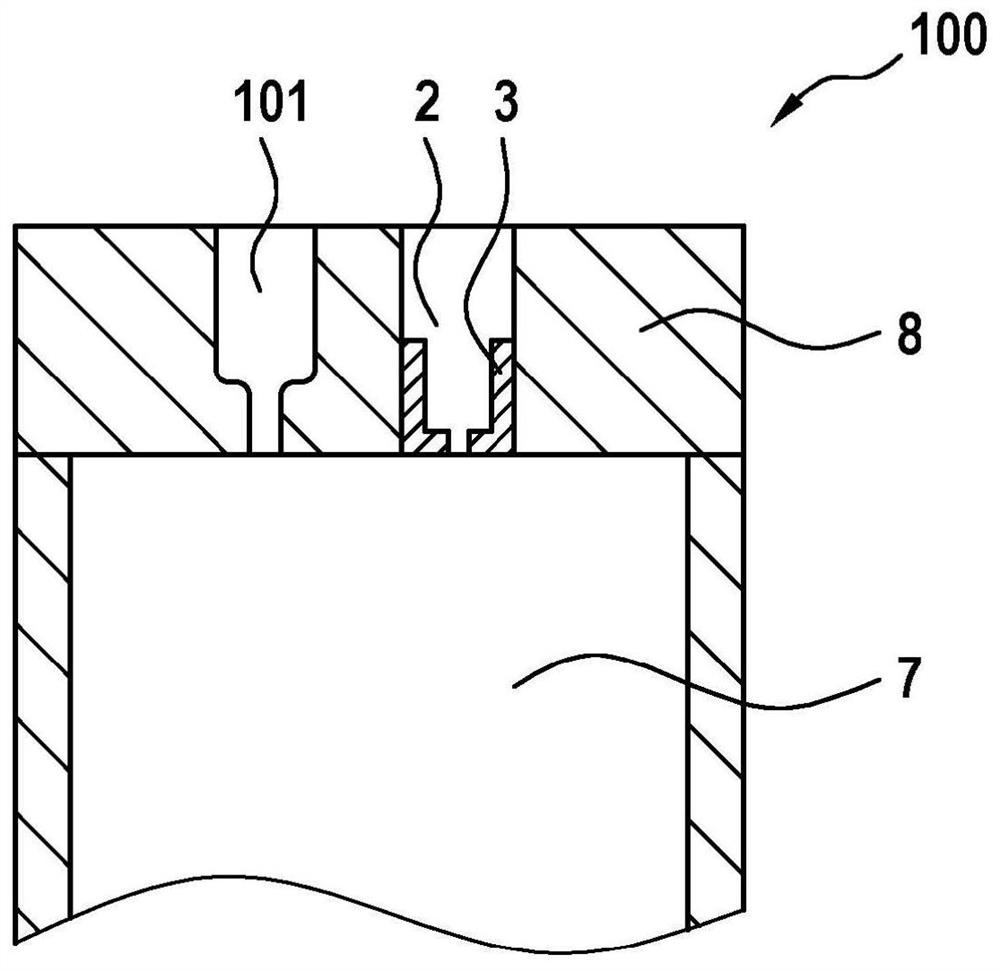

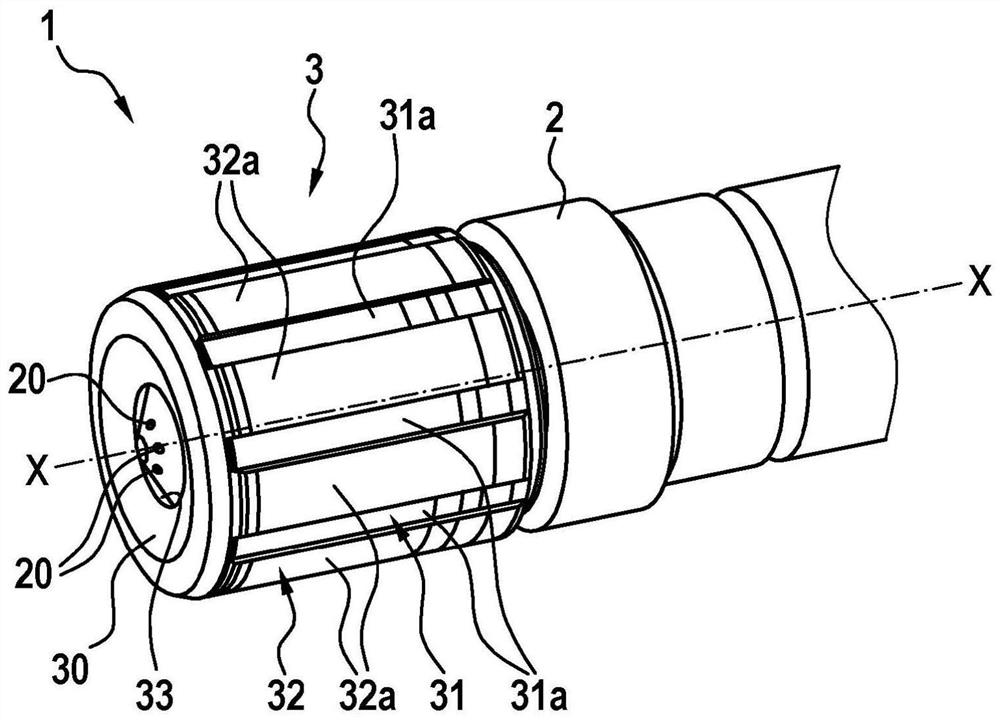

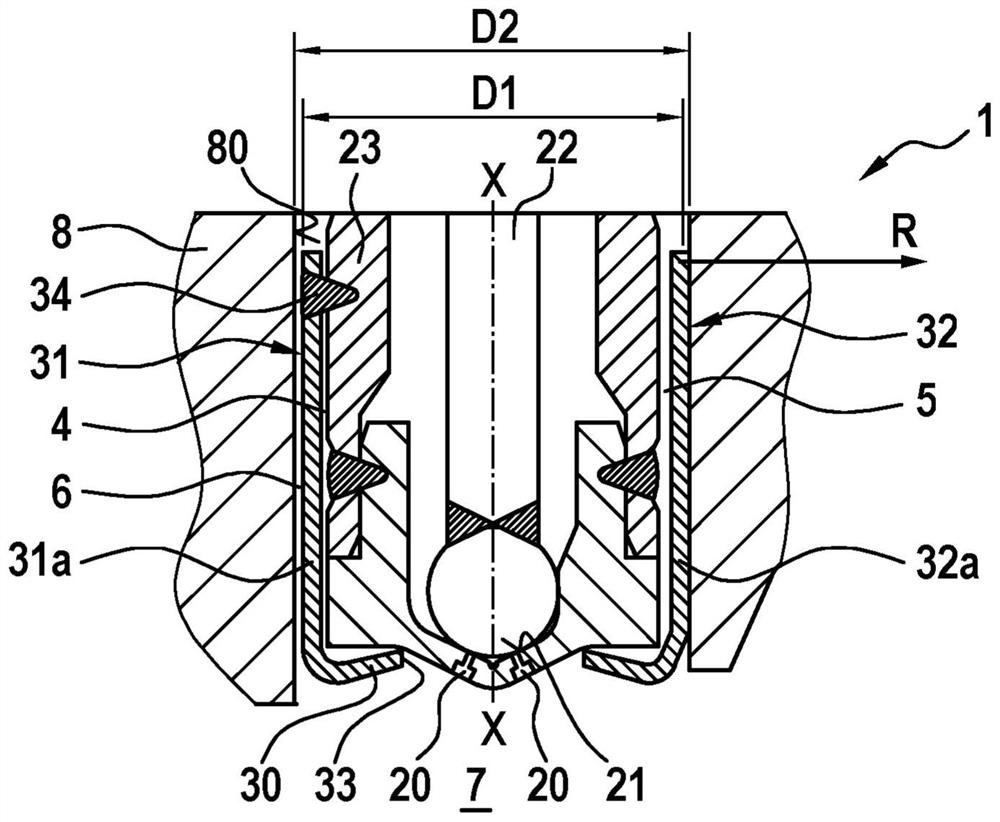

[0022] In the following, refer to Figures 1 to 3 The injector assembly 1 and the internal combustion engine 100 according to the preferred embodiment of the present invention are described in detail.

[0023] as from figure 1 and figure 2 As can be seen in the figure, the injector assembly 1 includes a liquid injector 2 , a thermal protection sleeve 3 and a gas injector 101 .

[0024] The thermal protection sleeve 3 partially surrounds the liquid injector 2, wherein, from figure 2 It can be seen that the region of the liquid injector 2 facing the combustion chamber 7 is surrounded by the thermal protection sleeve 3 .

[0025] The heat protection sleeve 3 has a base region 30 , a first peripheral region 31 and a second peripheral region 32 . A cylindrical opening 33 is provided in the bottom region 30 .

[0026] from image 3 It can be seen that the spray openings 20 of the liquid injectors 2 are arranged in the region of the openings 33 of the thermal protection sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com