Display panel and manufacture method thereof and display device

A display panel and substrate substrate technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of occupying pixel aperture ratio and low resolution of display panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Aiming at the problem in the prior art that the resolution of the display panel is low due to the aperture ratio of the pixels occupied by the infrared light-emitting part and the infrared photosensitive detection unit, the embodiments of the present invention provide a display panel, its manufacturing method and a display device.

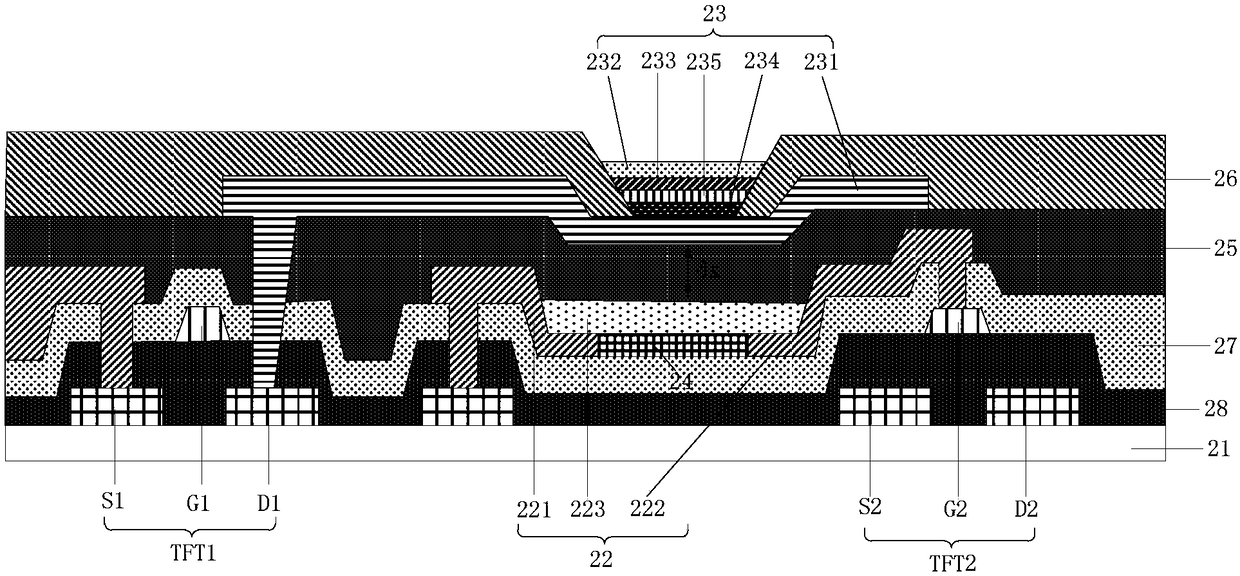

[0052] The specific implementation manners of the display panel provided by the embodiments of the present invention, its manufacturing method and the display device will be described in detail below with reference to the accompanying drawings. The thickness and shape of each film layer in the drawings do not reflect the real scale, and the purpose is only to illustrate the content of the present invention.

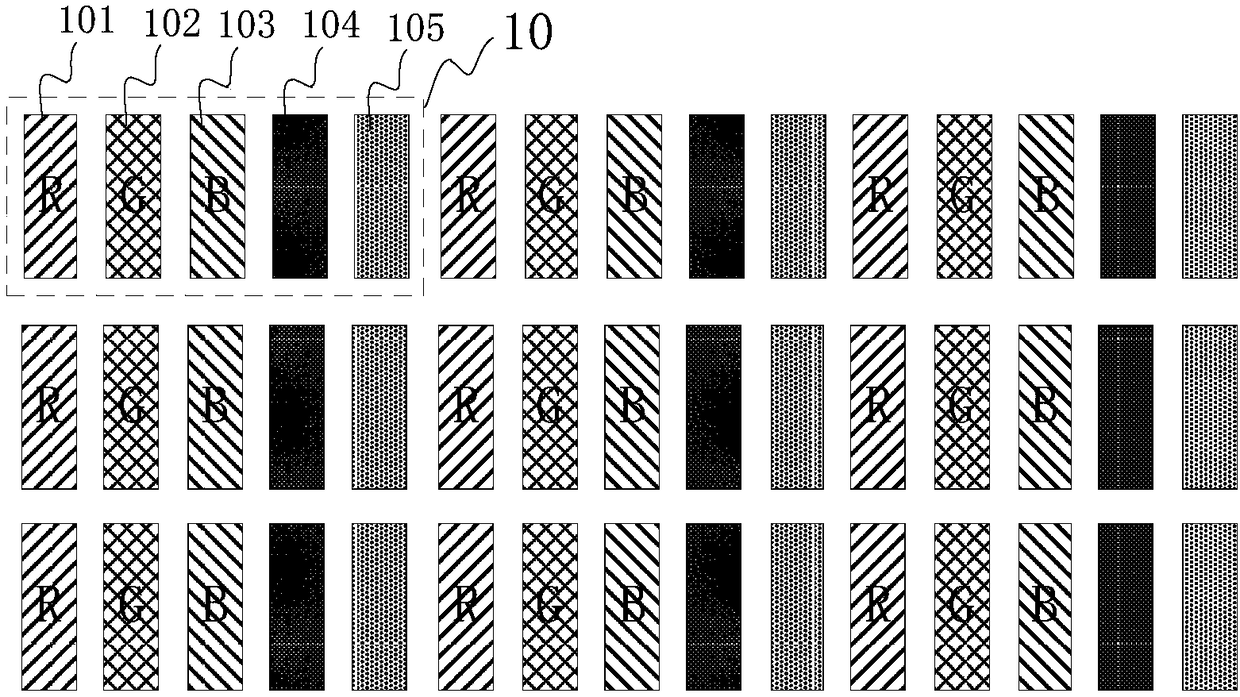

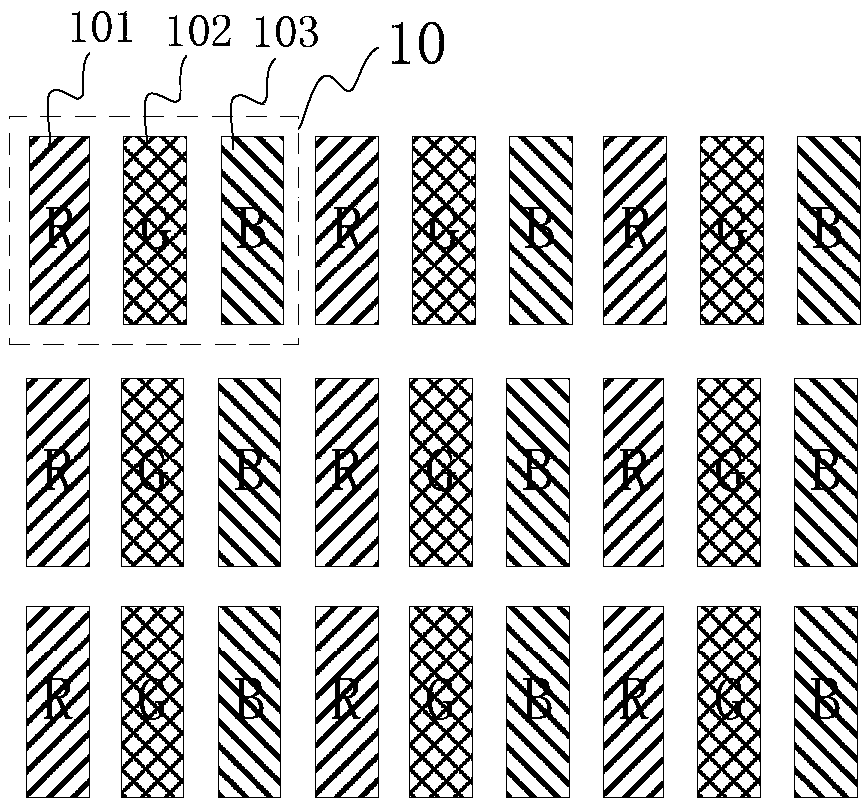

[0053] In a first aspect, an embodiment of the present invention provides a display panel, such as figure 2 and image 3 As shown, it includes: a base substrate 21, a plurality of pixels 10 arranged in an array on the base substrate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com