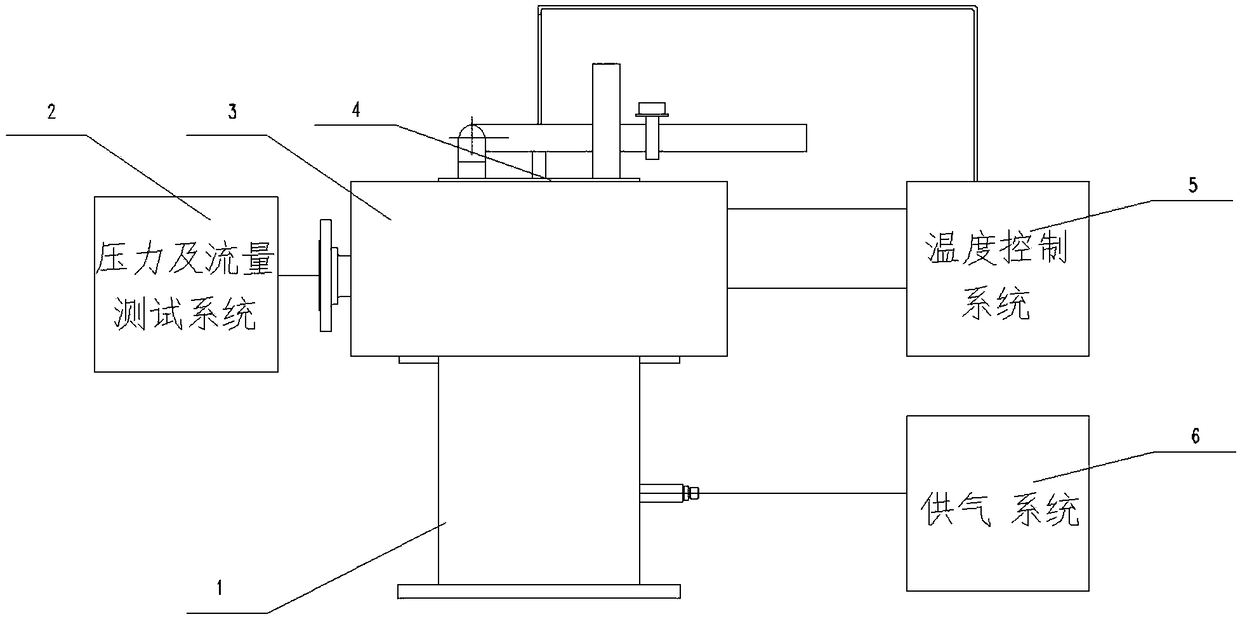

High-temperature sealing experimental device with continuously-adjustable sealing pressing force

An experimental device, sealing and pressing technology, which is applied in fluid tightness testing, measuring devices, testing of machine/structural components, etc., and can solve problems such as sealing experimental devices that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

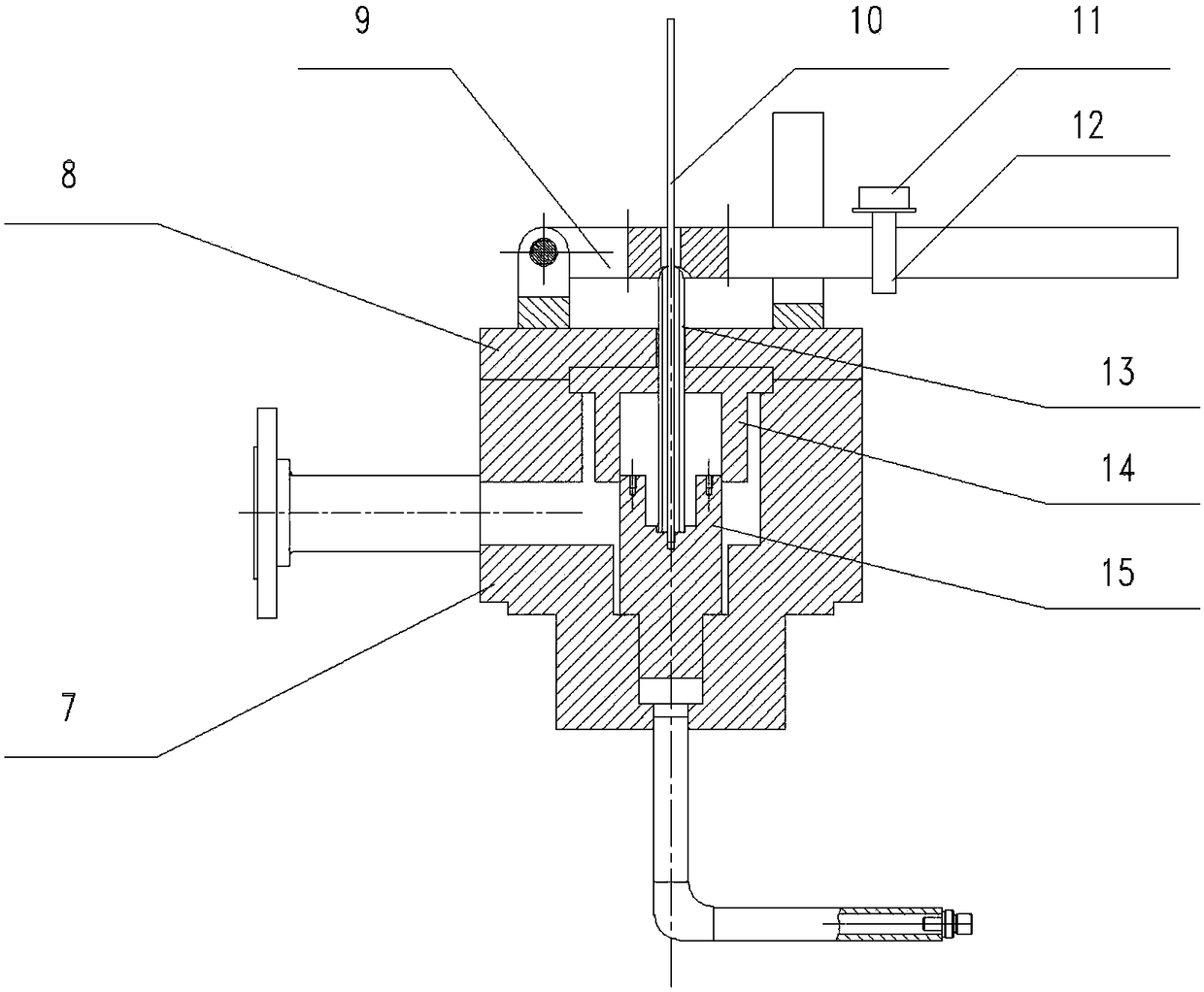

Embodiment 2

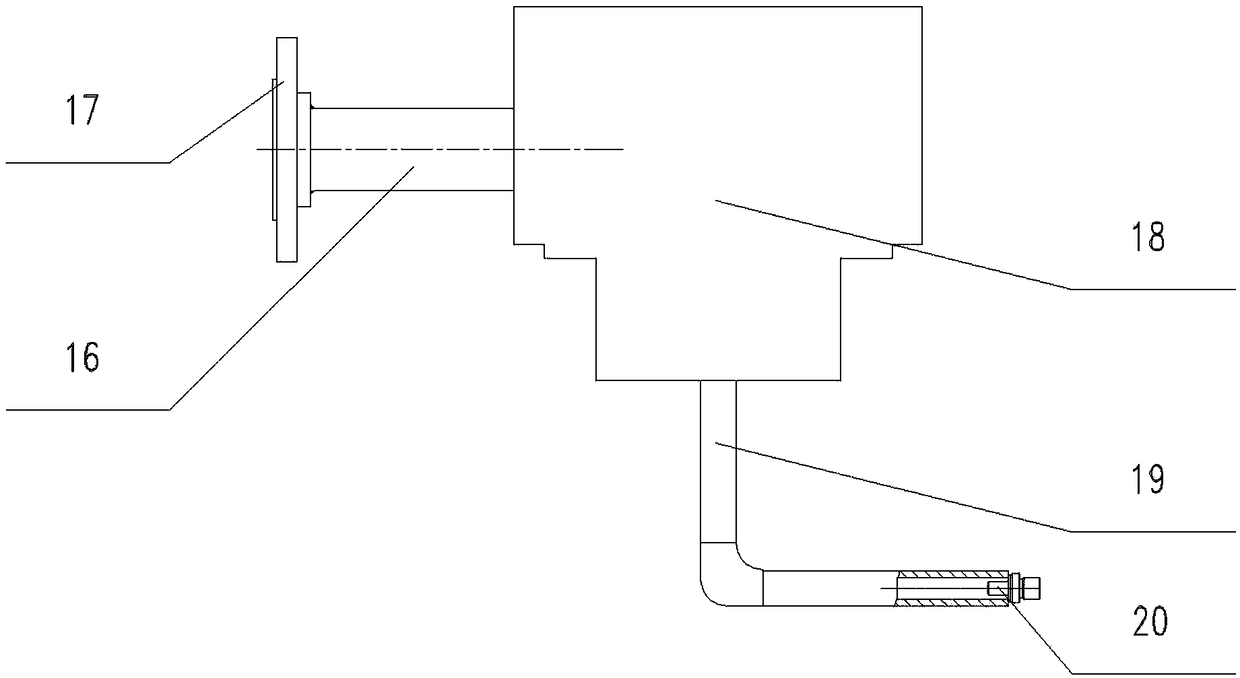

[0038] Fix the experimental device support 1 on the anchor bolts, then place the experimental device cavity 7 on the experimental device support 1, put the sealed test piece in the experimental device cavity 7 under the sealed lower core 15, and then Use the lower sealing core 15 to press the sealing test piece, install the temperature sensor 10 on the thread of the lower sealing core 15 , and make the wire of the temperature sensor 10 pass through the sensor conduit 13 to connect to the control system 5 . Afterwards, the sealing upper core 14 and the sealing lower core 15 are installed together to form a seal. The sealing cover 8 is fixed by screws and the cavity 7 of the experimental device. Complete the assembly of the main body of the experimental device. Install the pressing force loading and adjusting system lever 9 on the sealing cover 8, form a hinge fulcrum through bolt connection, and press the sensor conduit 13, so that the pressing force loading and adjusting syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com