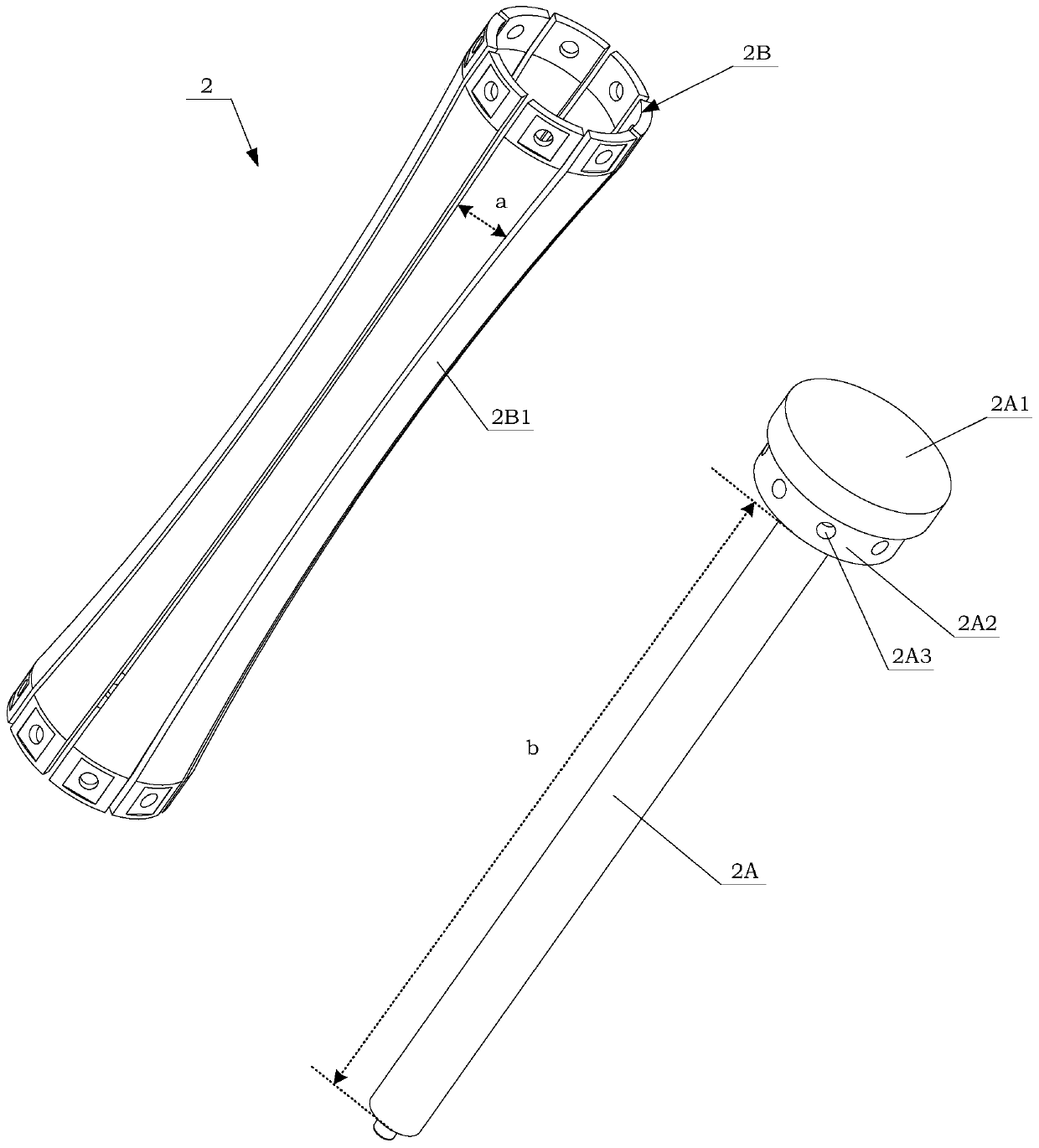

A Core Displacement Experimental System Based on Magnetostrictive Acoustic Transducer

A technology of acoustic wave transducer and magnetostriction, which is applied in the direction of wellbore/well components, measurement, production fluid, etc., to achieve the effect of large recovery and optimized technical means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] (1) Water flooding: Connect the plunger pump to the core, adjust the attitude of the core to be horizontal, inject water to displace the oil layer in the core, and the displacement speed is 3cm 3 / min, the water flooding continues until no more oil is produced, the water flooding recovery reaches the limit, and the water saturation in the core model reaches the maximum value. Record phase time oil production and water production.

[0108] (2) Low-frequency acoustic water flooding: After the water flooding is completed, connect the transducer device to the core through the valve interface, keep the attitude of the core horizontal, open the valve at the interface, and 3 Water is injected into the transducer sealing device at a flow rate of / min. At the same time, the transducer starts to work at a frequency of 104Hz and a power of 300W, and the valve at the outlet end of the core is opened to collect and discharge liquid. When the power of 300W is displaced until the tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com