Novel heat-insulating energy-saving aluminum alloy fire-resistant window

An aluminum alloy, energy-saving technology, used in windows/doors, fire doors, door/window accessories, etc., can solve the problems of general thermal insulation effect, inability to meet energy saving and emission reduction, poor thermal insulation performance of fire windows, etc. Good heat insulation effect, good radiation protection, non-flammable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

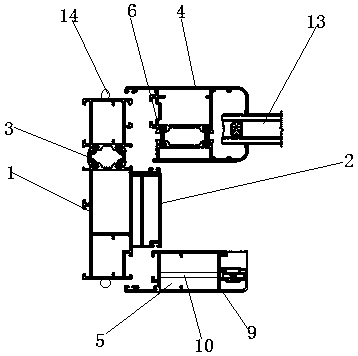

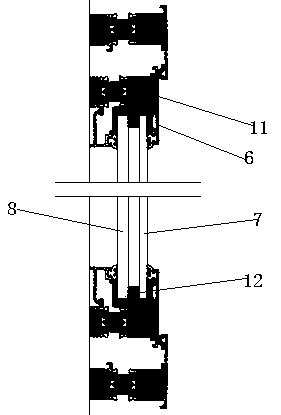

[0015] Such as figure 1 and figure 2 As shown, the novel heat-insulating and energy-saving aluminum alloy fire-resistant window of the present invention includes a bridge-broken window frame 1; the middle part of the bridge-broken window frame 1 is integrally formed with an inner and outer fan partition frame 2; the bridge-broken window frame The inner side of 1 is fixedly connected by heat insulation strip 3; the inner and outer sides of the broken bridge window frame 1 are respectively equipped with an outer fan 4 and an inner fan 5; Frame 6: Sponge silicon fireproof energy-saving glass 7 and inner LOW-E glass 8 are installed on the outside of the broken bridge fan frame 6; a hollow layer is arranged between the sponge silicon fireproof energy-saving glass 7 and inner LOW-E glass 8; The inner fan 5 includes an aluminum alloy inner frame 9; the aluminum alloy inner frame 9 is provided with tempered glass 10; the inner sides of the broken bridge window frame 1 and the broken...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com