Preparation method of polyacrylonitrile-based high-strength high-modulus carbon fibers

A high-modulus carbon fiber, polyacrylonitrile-based technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of simultaneous change, increase, and inability to match the related models of T series carbon fibers, and achieves lower processing temperature and higher tensile strength. The effect of stretching efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

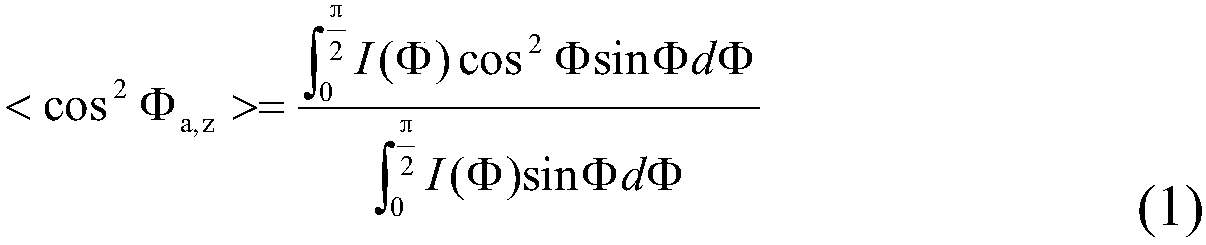

Image

Examples

Embodiment 1

[0032] (1) Pre-oxidation of PAN precursor

[0033] The 1K low-denier laboratory wet-process self-made PAN precursor was pre-oxidized in an air atmosphere using a gradient temperature rise method. The pre-oxidation start temperature was 210°C, the pre-oxidation end temperature was 255°C, and the pre-oxidation time was 45 minutes.

[0034] (2) Low temperature carbonization

[0035] Put the obtained pre-oxidized fiber into a low-temperature carbonization furnace for low-temperature carbonization treatment, using nitrogen as a protective gas, and the oxygen content in nitrogen is 1.0ppm. The low-temperature carbonization temperature is 700°C, and the low-carbon carbonization time is 3 minutes.

[0036] (3) High temperature carbonization

[0037] Put the obtained low-temperature carbonized fiber into a high-temperature carbonization furnace for high-temperature carbonization treatment, using high-purity nitrogen as a protective gas, and the oxygen content in nitrogen is 1.0ppm. Th...

Embodiment 2

[0042] (1) Pre-oxidation of PAN precursor

[0043] The Weihai extension 6K wet-process PAN precursor was pre-oxidized in an air atmosphere using a gradient heating method. The pre-oxidation start temperature was 200°C, the pre-oxidation termination temperature was 260°C, and the pre-oxidation time was 45 minutes.

[0044] (2) Low temperature carbonization

[0045] The obtained pre-oxidized fiber enters a low-temperature carbonization furnace for low-temperature carbonization treatment, using nitrogen as a protective gas, and the oxygen content in the nitrogen is 1.0 ppm. The low-temperature carbonization temperature is 750°C, and the low-carbon carbonization time is 3 minutes.

[0046] (3) High temperature carbonization

[0047] The fibers enter the high-temperature carbonization furnace after low-temperature carbonization, and high-purity nitrogen is used as the protective gas, and the oxygen content in nitrogen is 1.0ppm. The carbonization temperature is 1600°C, the carbo...

Embodiment 3

[0051] (1) Pre-oxidation of PAN precursor, (2) Low temperature carbonization

[0052] Same as Example 2

[0053] (3) High temperature carbonization

[0054] The obtained low-temperature carbonized fiber enters a high-temperature carbonization furnace for high-temperature carbonization, using high-purity nitrogen as a protective gas, and the oxygen content in the nitrogen is 1.0 ppm. The high-temperature carbonization temperature is 1650° C., the residence time is 2 minutes, and a relative stretching ratio of 96.8% is applied to both ends of the fiber during high-temperature carbonization treatment. The orientation angle of carbon crystallites in the obtained high-temperature carbonized fiber is 17.03°.

[0055] (4) High temperature graphitization

[0056] The obtained high-temperature carbonized fiber enters a graphitization furnace for high-temperature graphitization treatment, and nitrogen gas is used as a protective gas, and the oxygen content in the nitrogen gas is 1.0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com