Auxiliary processing device for food

An auxiliary processing and food technology, applied in food science, baking, dough forming machinery or equipment, etc., can solve the problems of long distance, poor toughness of ramen noodles, bad taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below.

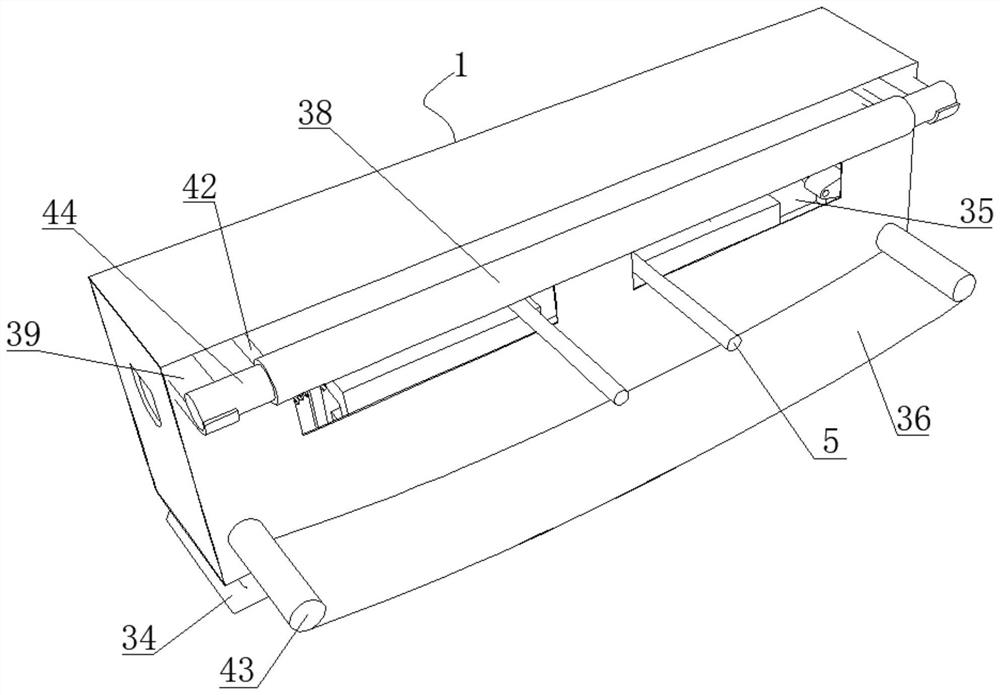

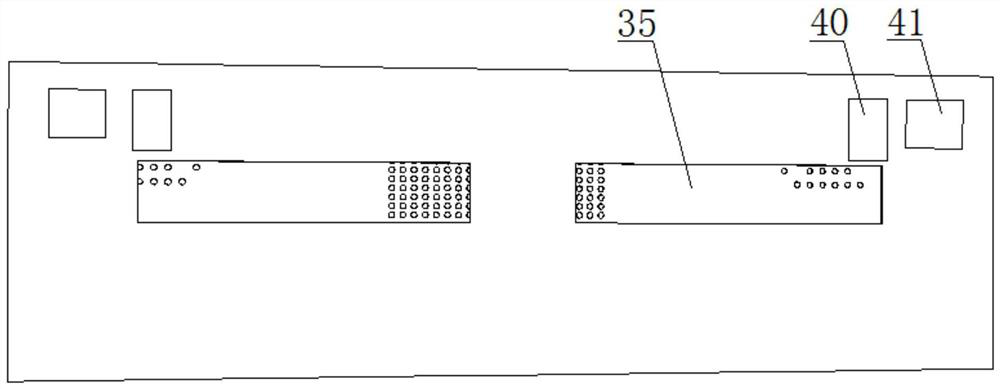

[0025] Such as Figure 1 to Figure 6 As shown, a food auxiliary processing device includes a box-type casing 1, two stretching mechanisms 2 symmetrically arranged inside the box-type casing 1, and a hollow roller 38 arranged outside the box-type casing 1 ; The left and right sides of the middle part of the front panel of the box-type housing 1 are symmetrically opened with two strip-shaped through holes A35 extending laterally, and a supporting plate 36 is fixedly connected below the two strip-shaped through holes A35;

[0026] Two through-holes A41 are symmetrically opened on the left and right ends of the upper front panel of the box-type housing 1, and two vertically extending strip-shaped through-holes B40 are opened on the inside of the two through-holes A;

[0027] The stretching mechanism 2 includes an inner support plate 3, an outer support plate 4, a transverse reciprocating drive mechanism, a noodle str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com