Additive capable of regulating coating gloss and preparation method thereof

A kind of additive preparation and additive technology, applied in the direction of coating, etc., can solve the problems of color deviation of the construction coating film, increase the thickness of the paint film, waste pigment toning, etc., to reduce floating color and flowering, increase permeability, and improve adsorption performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

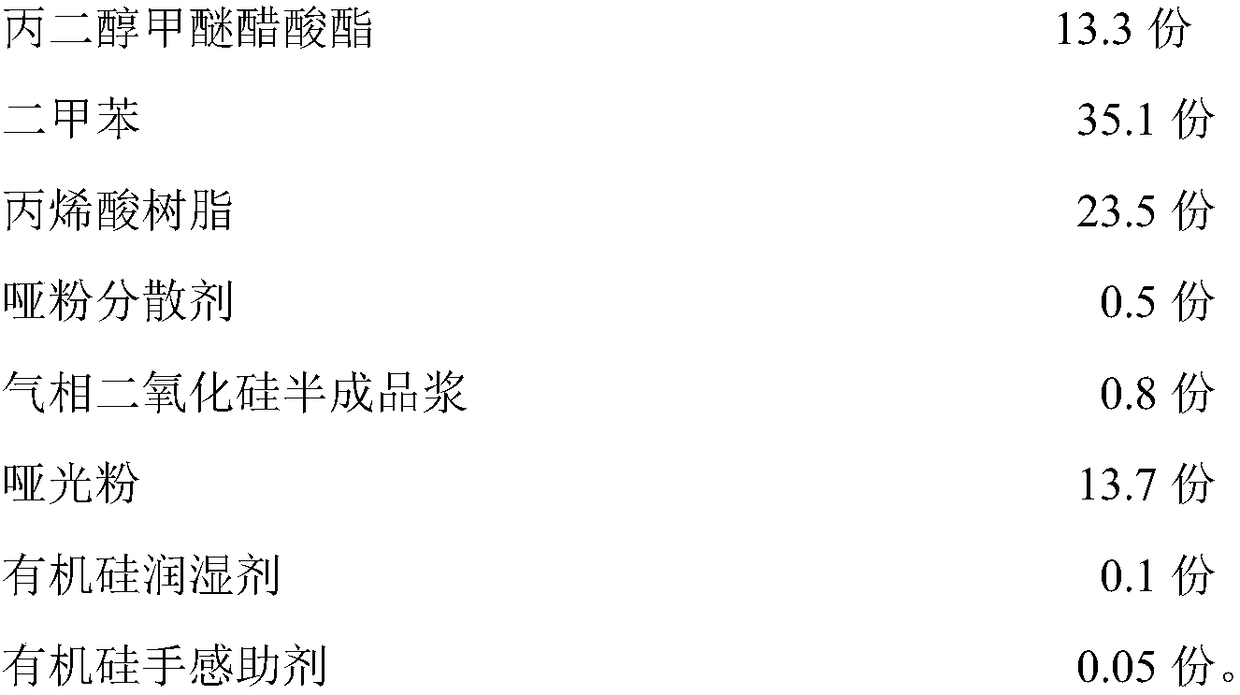

[0036] Preparation of additives that can control the gloss of paint

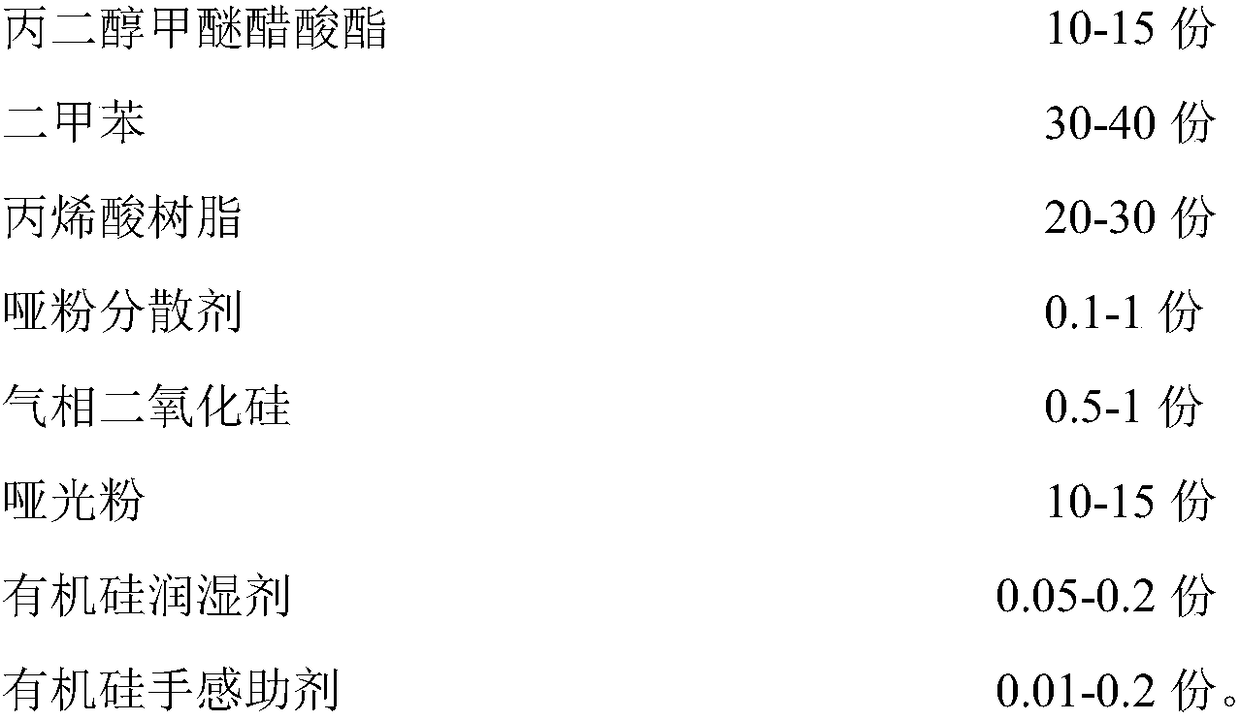

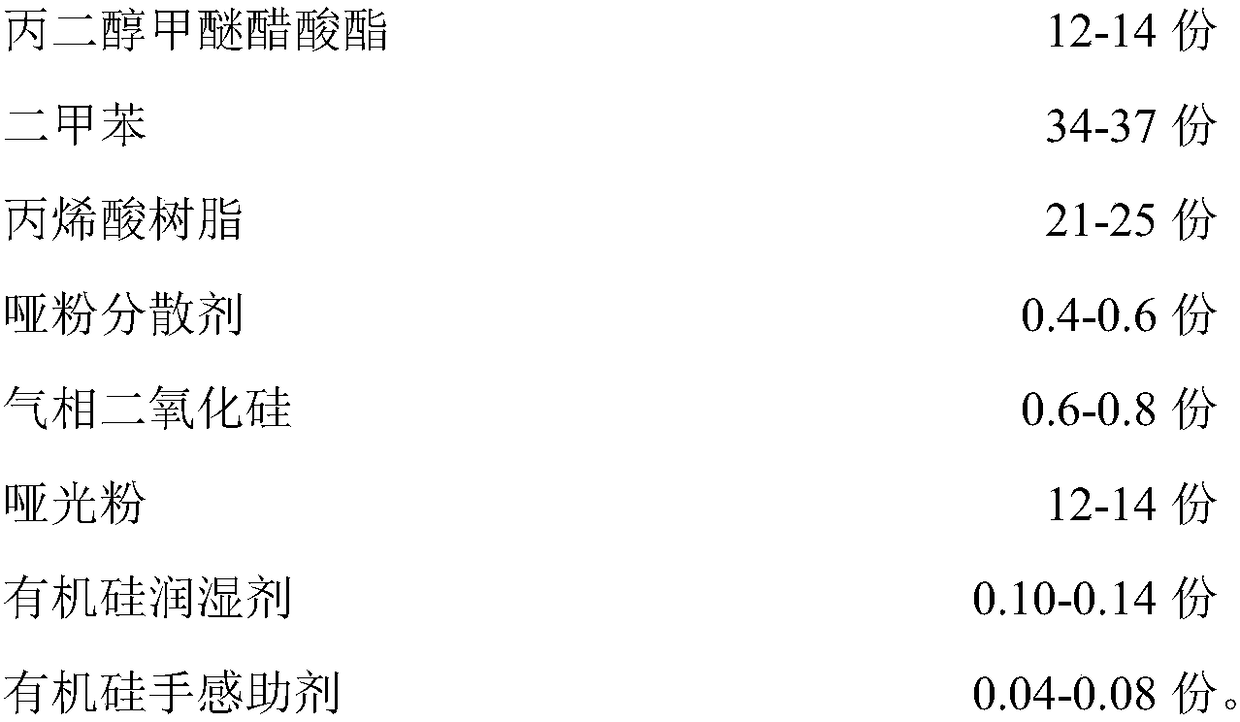

[0037] The formula of additive is as shown in table 1, and its preparation process is as follows:

[0038] (1)) Drop into 30wt% propylene glycol methyl ether acetate, 15wt% xylene, 20wt% matte powder dispersant, all fumed silica and 20wt% acrylic resin successively in the container according to the formula quantity, mix well, stir speed 600-900 rev / min, after stirring for 20-40 minutes, grind the mixture. In order to improve production efficiency, first grind the fineness of fumed silica to a fineness of ≤15 μm to obtain fumed silica semi-finished slurry;

[0039] (2) drop propylene glycol methyl ether acetate, xylene, acrylic resin and mat powder dispersant into the container according to the formula amount, stir evenly, and the stirring speed is 600-900 rpm to obtain the mixture A;

[0040] (3) Put fumed silica semi-finished slurry into mixture A, stir evenly, and the stirring speed is 600-900 rpm to obta...

Embodiment 2

[0055] Table 4 is the feeding formula for changing the content of each substance under the condition that the types of substances in the formula are kept unchanged in Example 1, and the additives are prepared according to the preparation process of Example 1.

[0056] The properties of the additives prepared by formula 6-9 are shown in Table 5. Compared with the properties of Table 2, it can be seen that when the content of each component raw material exceeds the range disclosed in Table 1 in Example 1, the additives are added to the paint, and the obtained paint The performance of the membrane is drastically reduced in all aspects.

[0057] Table 4 Additives of different formulations

[0058]

[0059] The paint film performance testing data that the additive that table 5 formula 6-9 obtains is used in conjunction with paint and obtains

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com