Multi-station automatic workpiece punching method

A multi-station and workpiece technology, applied in the field of stamping, can solve the problems of reducing stamping efficiency and achieve the effect of improving stamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

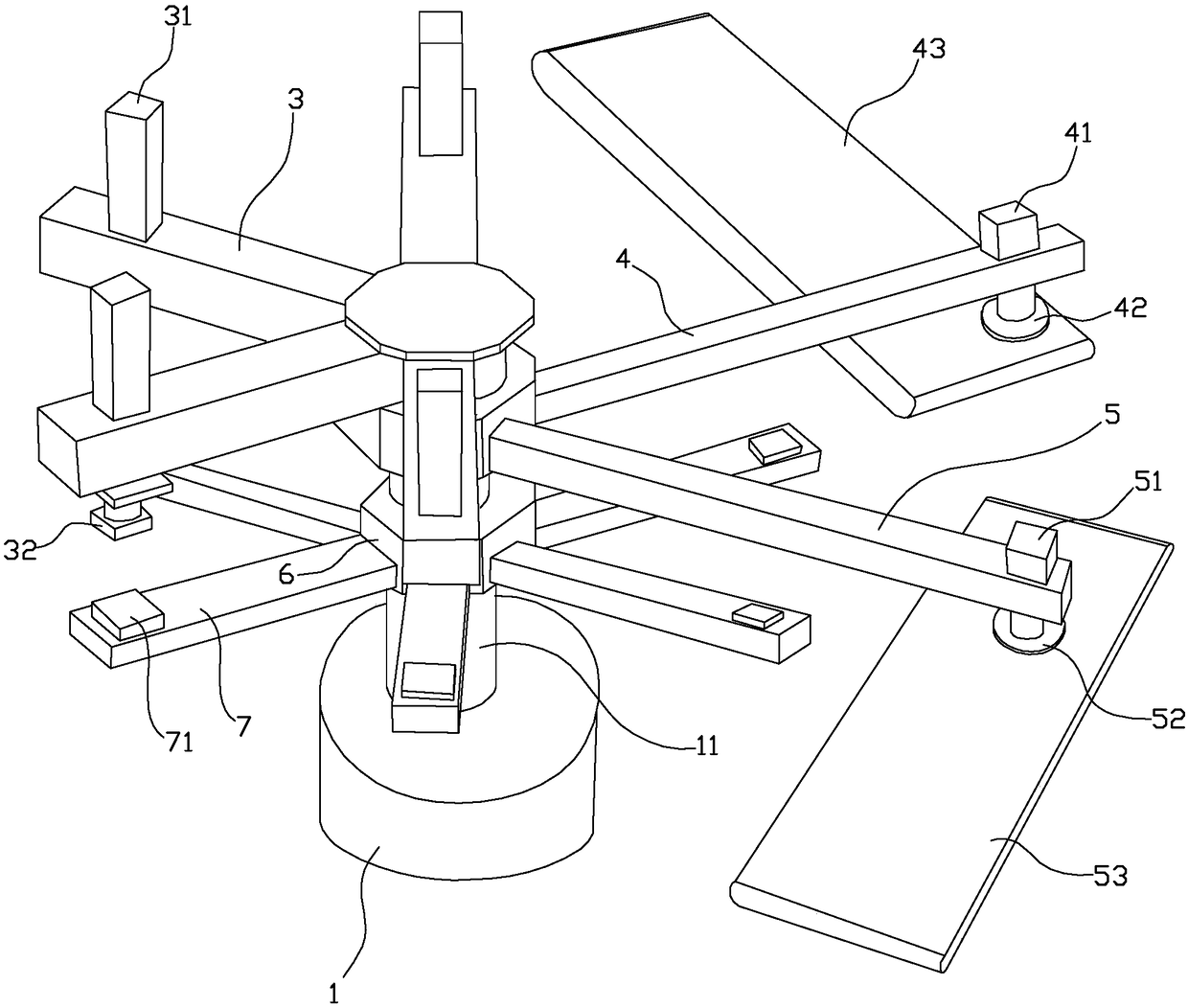

[0017] First, this embodiment describes the multi-station automatic stamping device involved in the multi-station automatic stamping method of the present invention. Such as figure 1 As shown, the multi-station automatic stamping method of the workpiece in this implementation includes a platform 1, a column 11, an upper beam 3, a stamping cylinder 31, an upper die 32, a feeding rod 4, a feeding cylinder 41, a feeding suction cup 42, Discharge rod 5, discharge cylinder 51, discharge suction cup 52, feeding conveyor belt 43, discharge conveyor belt 53, turntable 6, lower beam 6, lower die 61.

[0018] Wherein, there is a column 11 erected on the platform 1, and N upper beams 3 are fixed radially on the top of the column 11, and the outer end of each upper beam 3 is provided with a stamping cylinder 31, and the output end of the stamping cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com