An automatic stamping method for realizing multi-station continuous stamping of workpieces

A multi-station, workpiece technology, applied in the stamping field, can solve problems such as reducing stamping efficiency, and achieve the effect of continuous stamping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

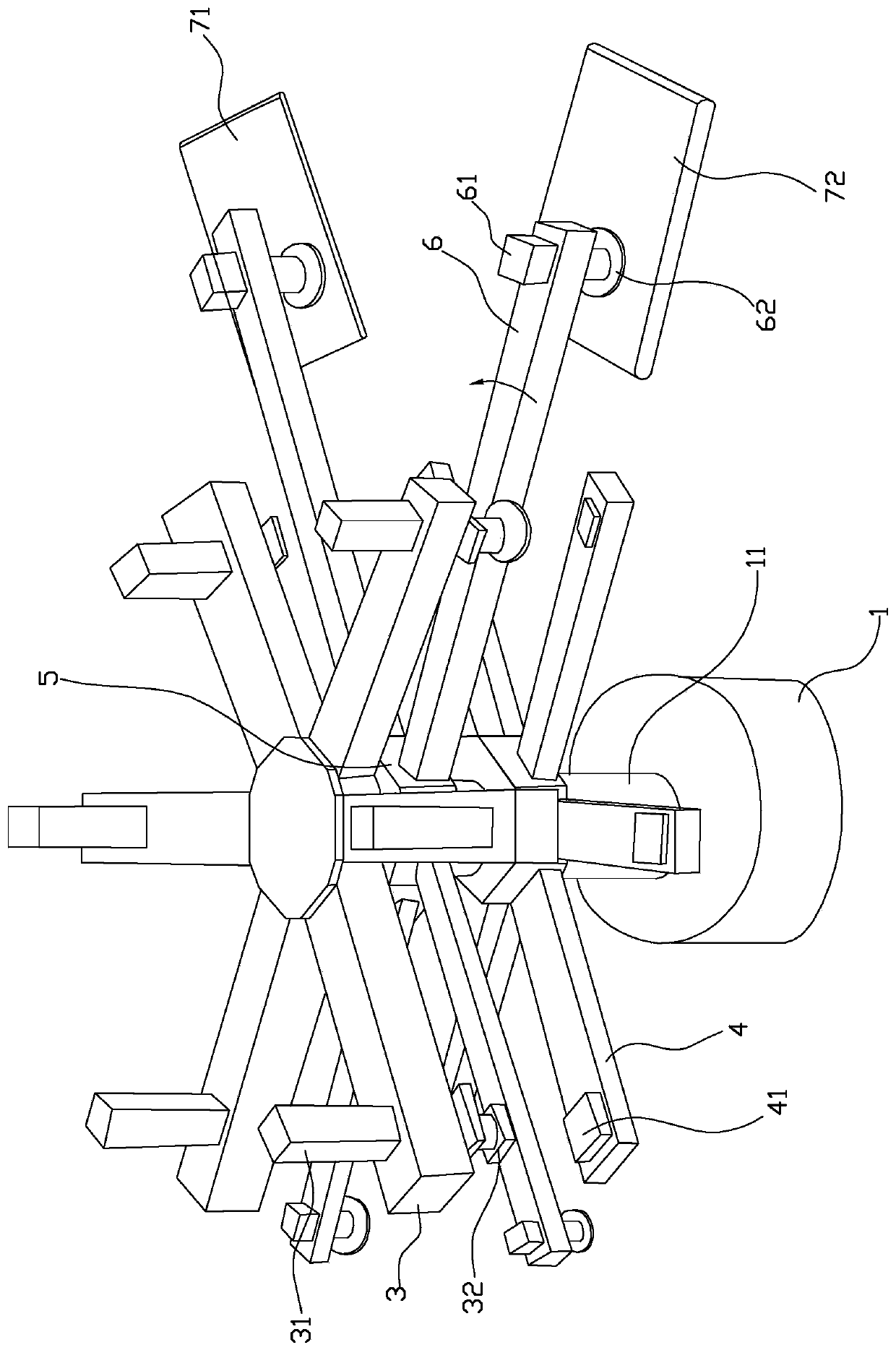

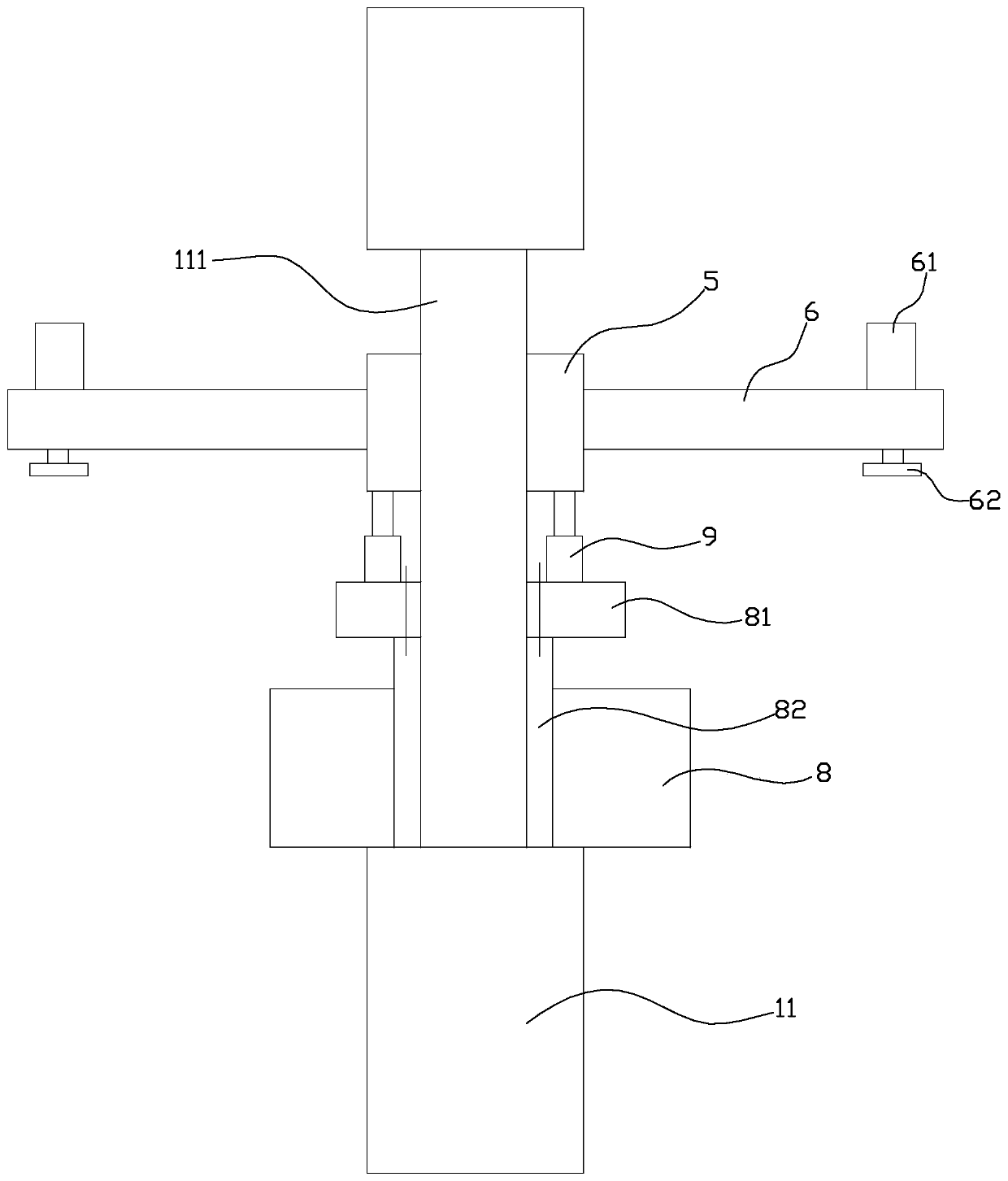

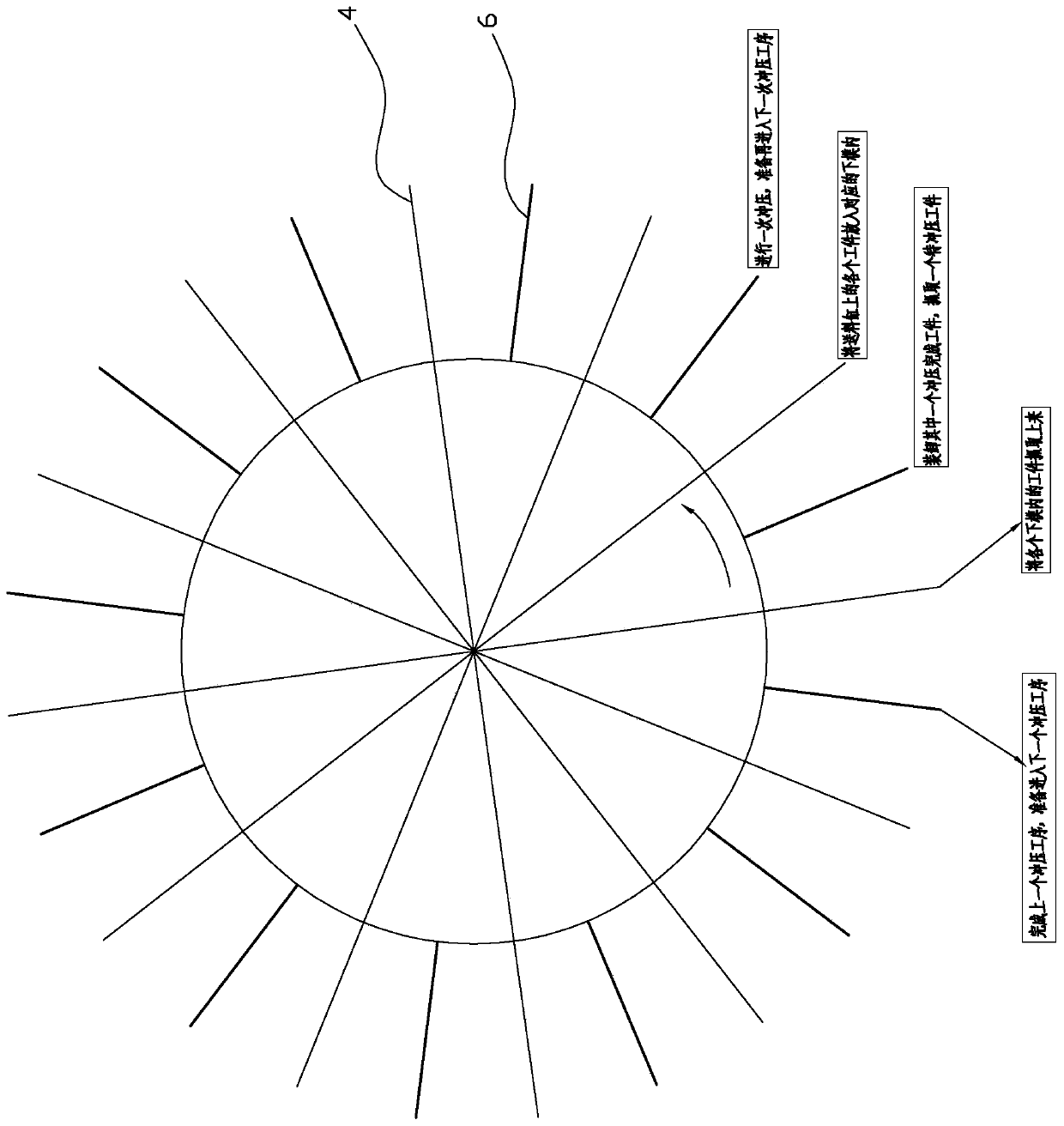

[0022] First, the automatic stamping device for realizing multi-station continuous stamping of workpieces involved in the present invention will be described. like figure 1 , 2 As shown, the automatic stamping device for realizing multi-station continuous stamping of the workpiece in this implementation includes a platform 1, a column 11, an upper beam 3, a stamping cylinder 31, an upper mold 32, a support rod 6, a feeding cylinder 61, a suction cup 62, an upper Material conveyor belt 71, discharge conveyor belt 72, turntable 5, lower beam 4, lower die 41, hollow motor 8, lifting cylinder 9, fixed plate 81.

[0023] Wherein, a column 11 is erected on the platform 1, and the top of the column 11 is radially fixed with N evenly distributed upper beams 3, N≥2, and the outer end of each upper beam 3 is provided with a stamping cylinder 31, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com