Drying and crushing device for cultivated excrement

A technology of drying and crushing manure, which is applied in the field of livestock breeding, can solve the problems of inability to crush manure, reduce fertilizer efficiency, and heavy environmental odor, and achieve the effects of easy packaging and storage, strong practicability, and long-lasting fertilizer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

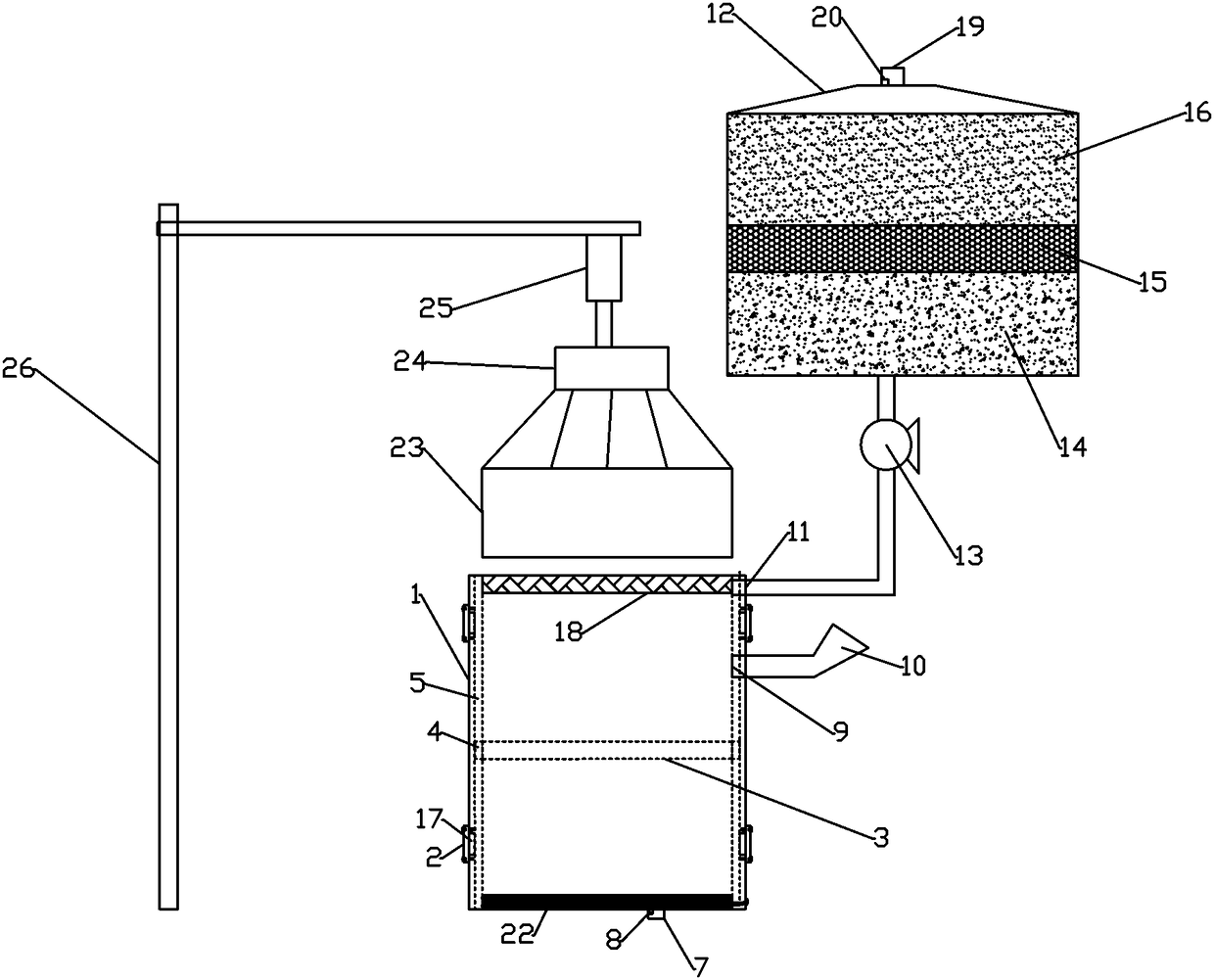

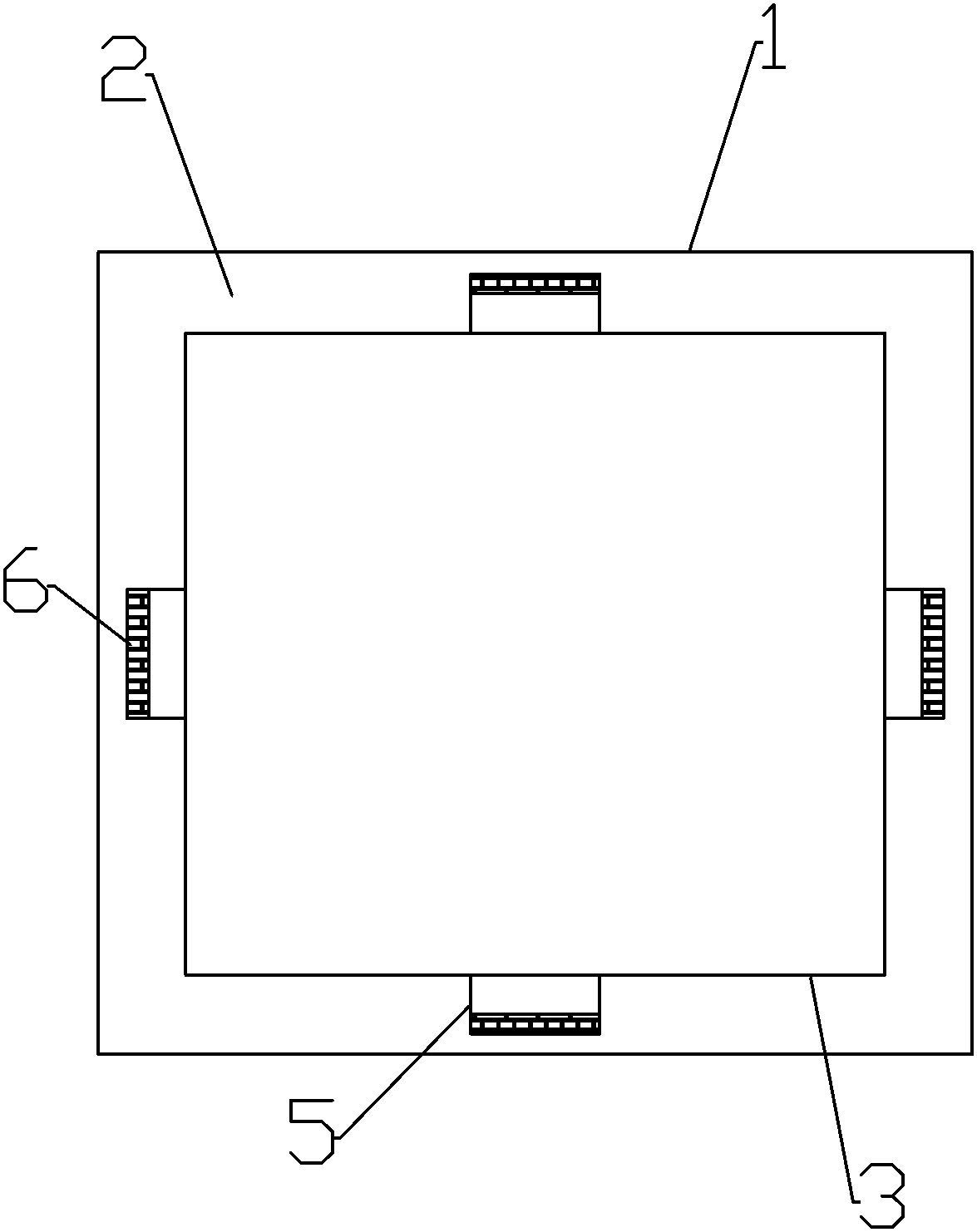

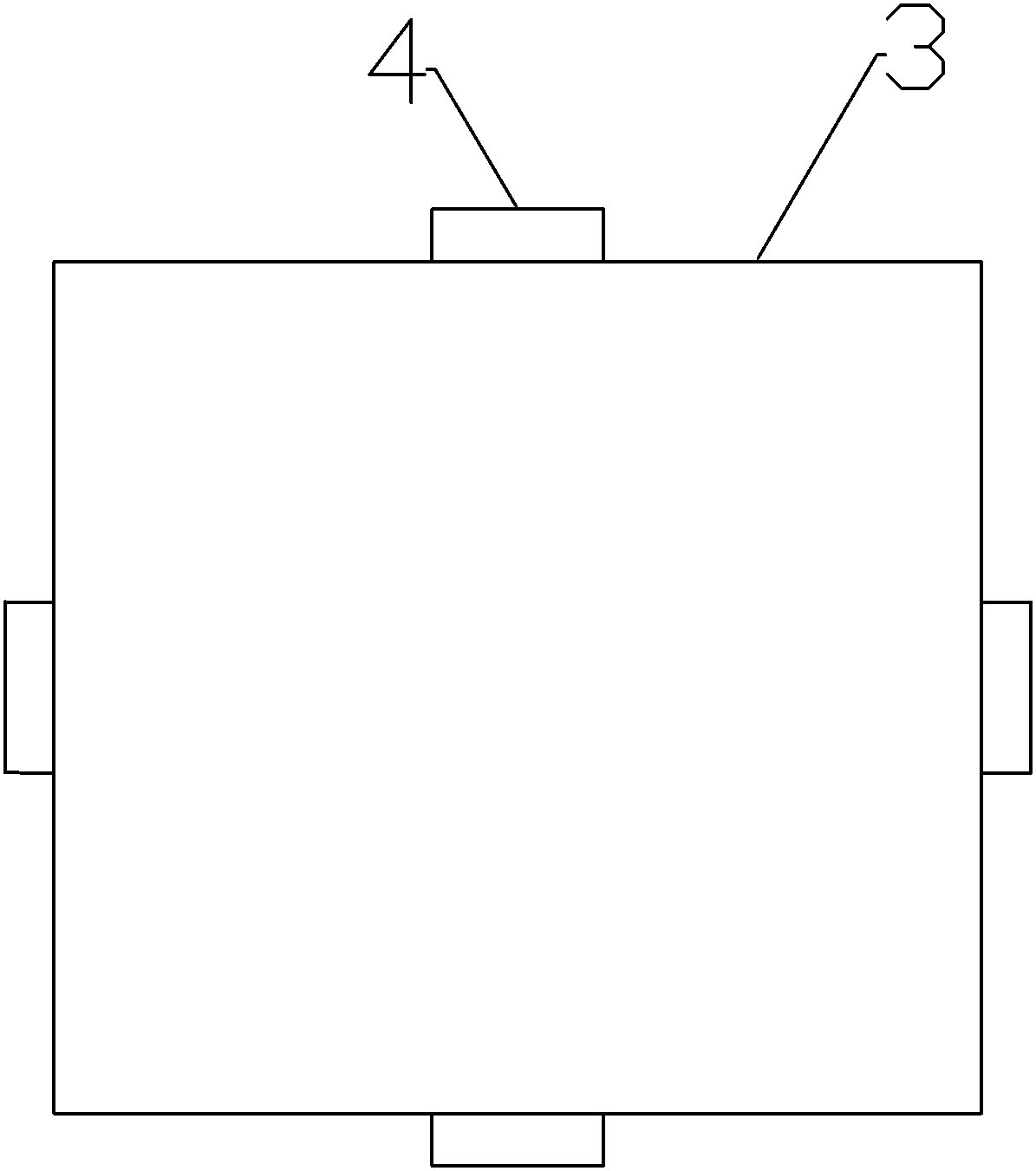

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] A kind of farming manure drying and pulverizing device, such as Figure 1-5 As shown, including the housing 1, the inner wall of the housing 1 is uniformly provided with a slideway 5, the slideway 5 is provided with a through hole 6, the outer side of the housing is provided with a fixing seat 2, and the inner surface of the fixing seat 2 is provided with a through hole 6 The matching copper sliding plate 17, the copper sliding plate 17 reduces the friction force when the heat conduction partition 3 slides in the slideway 5, and at the same time, the copper sliding plate 17 is installed from the outside of the housing 1, which is convenient for smoother and maintenance. The body 1 is fixedly connected, and the inside of the shell 1 is provided with a heat-conducting partition 3, which is arranged horizontally so that the interior of the shell 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com