Linear fruit paper bag

A paper bag and glyph technology, which is applied in the field of fruit paper bags and fruit bagging, can solve the problems of lack of specifications, different specifications, unfavorable fruit bagging operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

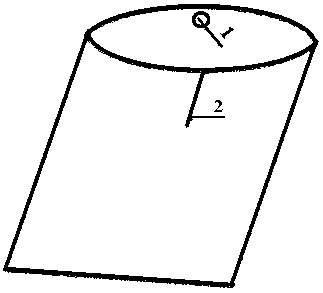

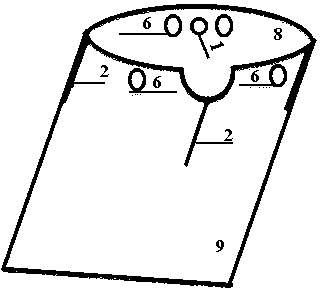

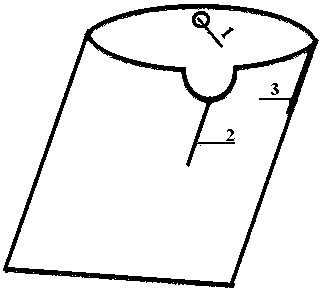

[0027] see Figure 1-10 , a one-shaped fruit paper bag, the upper end of the paper bag is an open end, the height of the back 8 of the paper bag coincides with the height of the front 9, at least one complete positioning hole or groove 1 is provided on the back or the upper end of the front and rear sides of the paper bag, and the center position of the upper end of the front of the paper bag is downward Opening line 2 is set, and the bottom surface is in-line or oval, and the side is in-line paper bag. The positioning hole 1 or the positioning groove 1 is mainly to solve the problem of uniform paper bag specifications. Due to the processing technology and precision problems, the actual size of the paper bags is not the same for paper bags of the same specification, which brings many problems to the operation of the automatic bagging equipment. This problem can be solved if the positioning hole is provided, and the difference in the actual size of the paper bag can be avoided ...

Embodiment 2

[0031] see Figure 9-10 , a kind of inline fruit paper bag, the upper end of the back of the paper bag is provided with at least one opening hole 6 or bag opening groove 6, its position is not higher than the positioning hole and the bottom of the bag opening hole or groove is not higher than the upper edge position of the front of the paper bag. The setting of bag opening hole or groove 6 can solve the opening problem of the paper bag, and provides multiple options for the opening method of the paper bag. The setting of opening bag hole or groove 6 quantity depends on the requirement of automatic bagging equipment, can be one, also can be multiple. You can choose to open the bag through the hole slot, or you can choose to insert the opening from the mouth of the paper bag, etc.

Embodiment 3

[0033] see Figure 2-10 , a kind of inline fruit paper bag, the opening line 2 is arranged downward at the center position of the upper end at the back of the paper bag. The opening line 2 is set downwards at the upper end position of one side or both sides of the paper bag. The function of setting the opening line at the back or on both sides of the paper bag is mainly designed for some short-stalked fruits. Due to the short stem of short-stalked fruits, it is difficult to expose the stem to the paper bag when bagging. When necessary, the paper bag can be sealed on the leaves or fruit branches, and the method of setting the opening line can be very convenient. a little. The upper end of the front or the front and rear sides of the paper bag is provided with a notch, and the lower end of the notch is provided with an opening line downward, and the symmetry axis of the notch coincides with the opening line. Also be this purpose, in order to load after fruit, more convenient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com