Integral dropper vibration fatigue tester

A vibration fatigue and testing machine technology, applied in the field of testing machines, can solve problems such as bow scraping accidents, pantograph-net failures, and threats to driving safety, and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

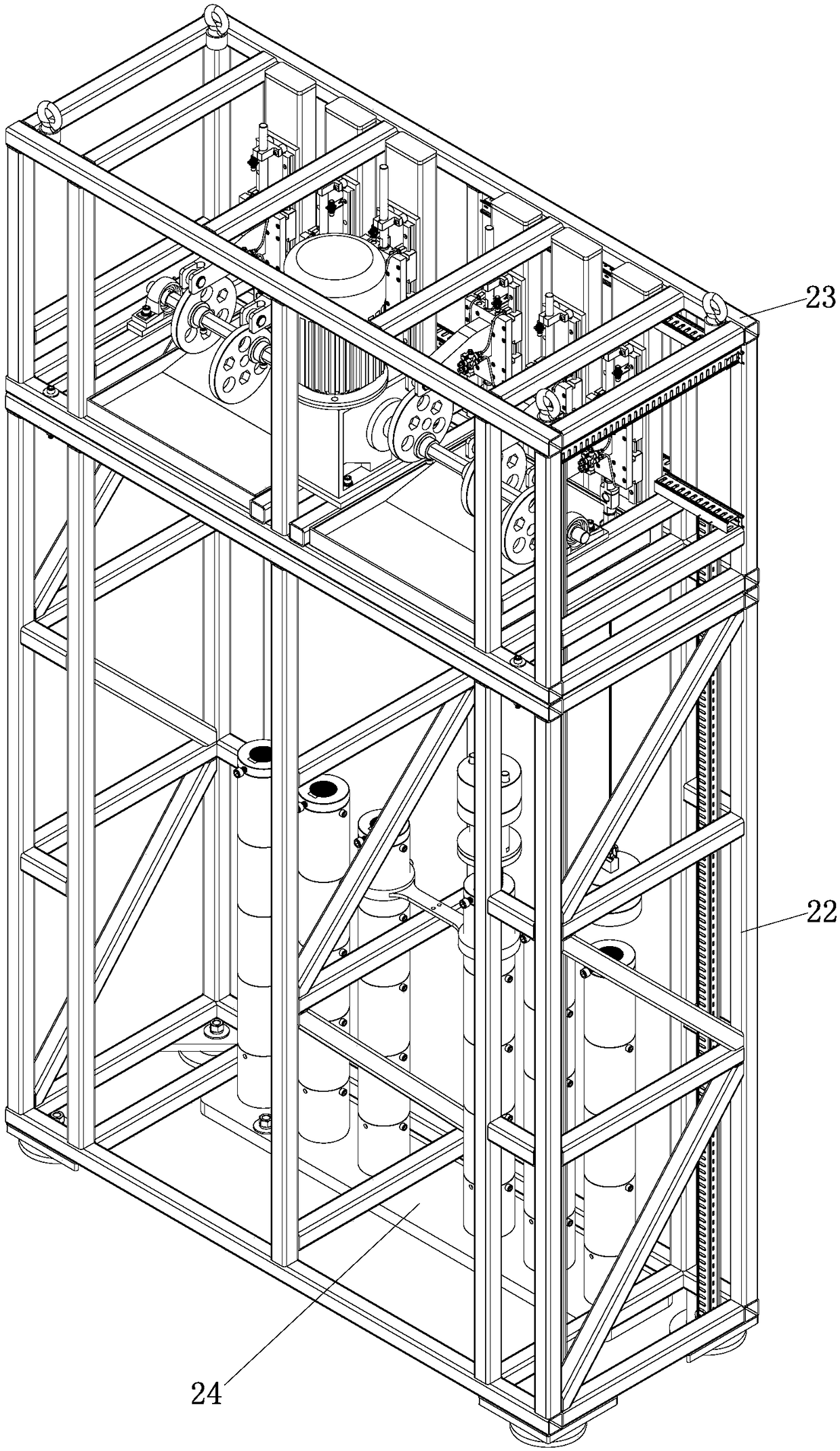

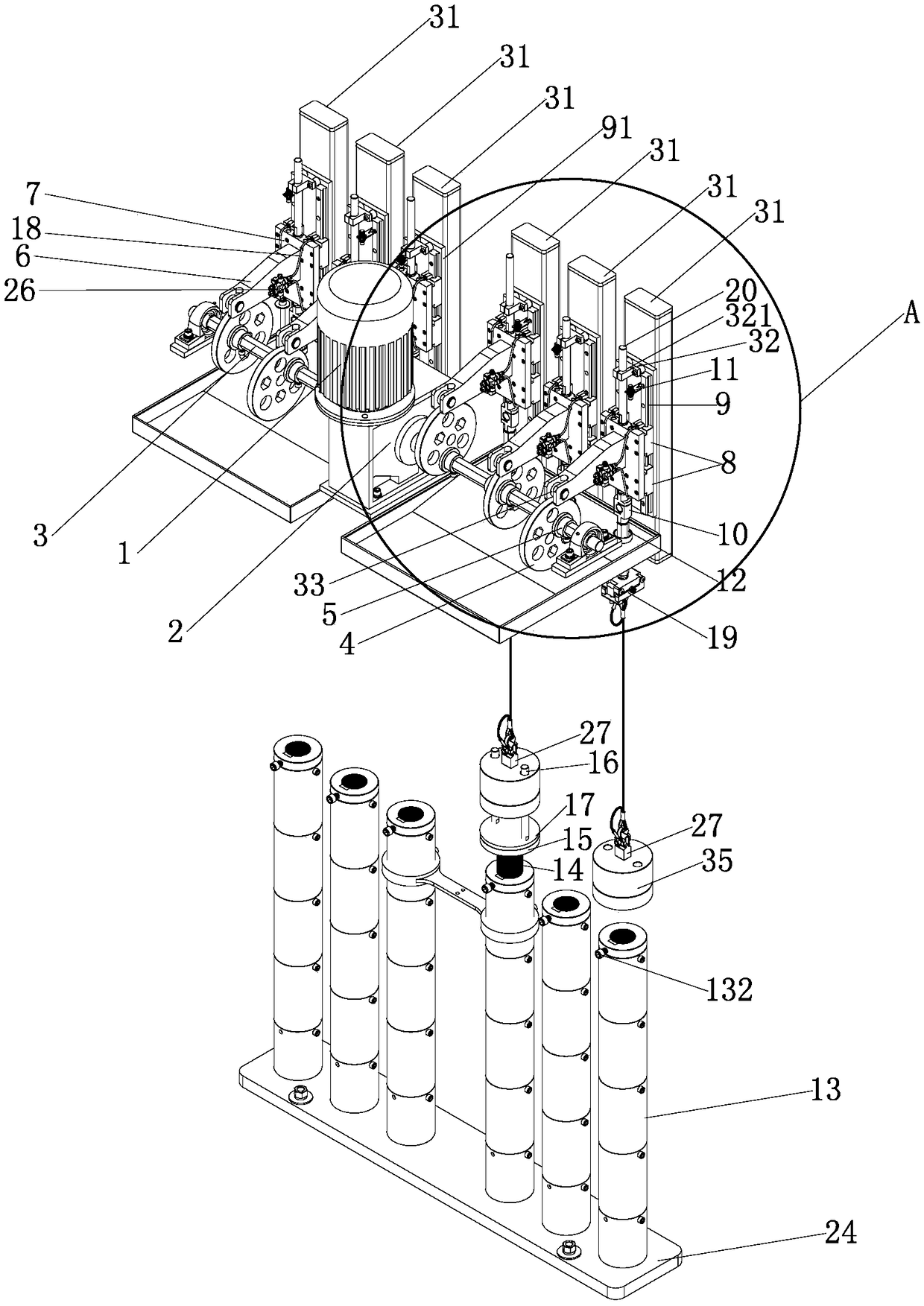

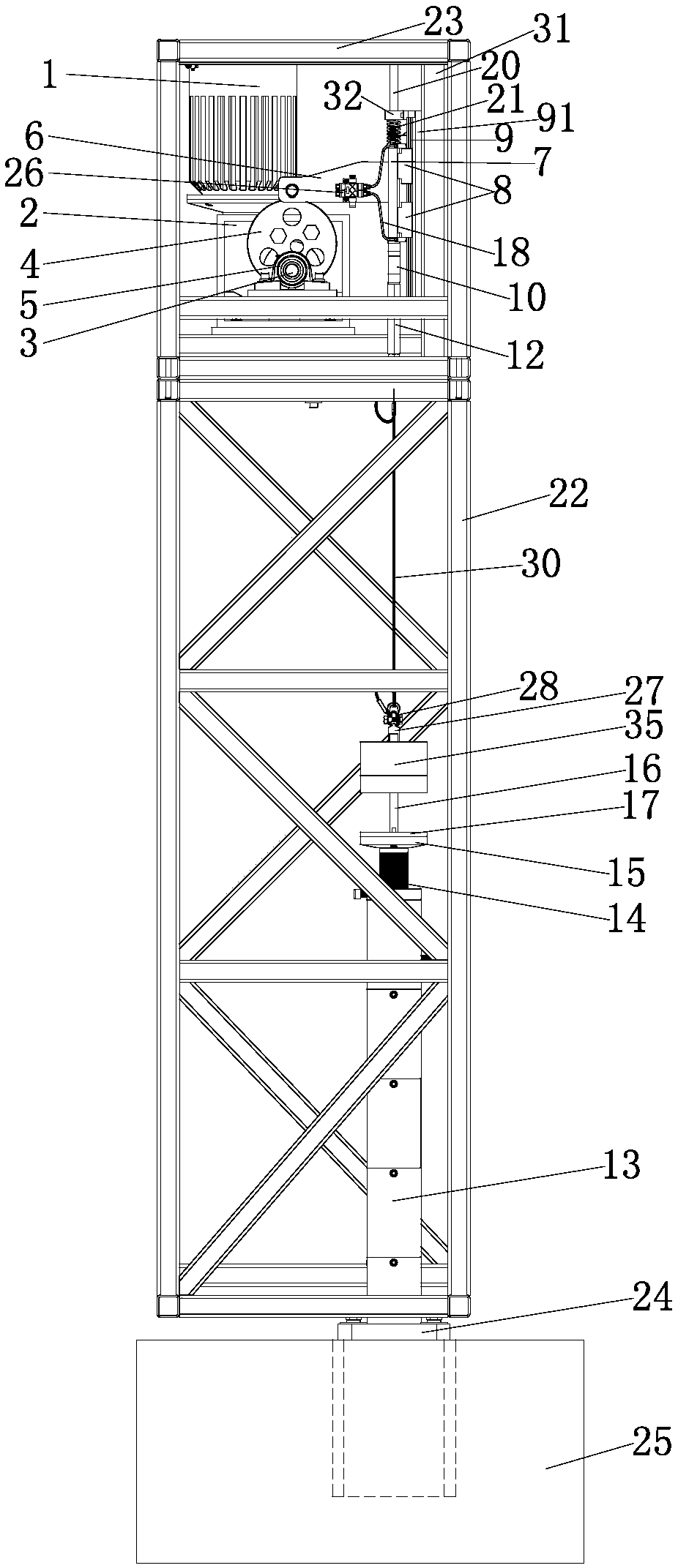

[0030] combine Figure 1 to Figure 4 As shown, the overall hanging string vibration fatigue testing machine of the present invention comprises a frame and a main frame positioned at the frame. The frame includes a main frame 22 and a drag frame 23 fixed on the top of the main frame 22. The main frame includes a mounting base plate 24, a fixed A driving device on the drag frame 23, and six parallel test devices with the same structure.

[0031] combine figure 1 and figure 2 As shown, the driving device includes a variable frequency motor 1 and a reducer 2 . Each test device includes an eccentric wheel 4, an eccentric wheel fixing flange 5, a movement mode conversion mechanism and a length adjustment device. The output shaft of the reducer 2, that is, the transmission main shaft 3 is a hexagonal transmission main shaft. Three hexagonal holes matching the transmission main shaft 3 are respectively opened on the eccentric wheel 4 at 35mm, 60mm, and 75mm from the center of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com