A gas pipeline pipe wall defect detection device

A gas pipeline and defect detection technology, which is used in measuring devices, fluid tightness testing, and machine/structural component testing. The effect of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

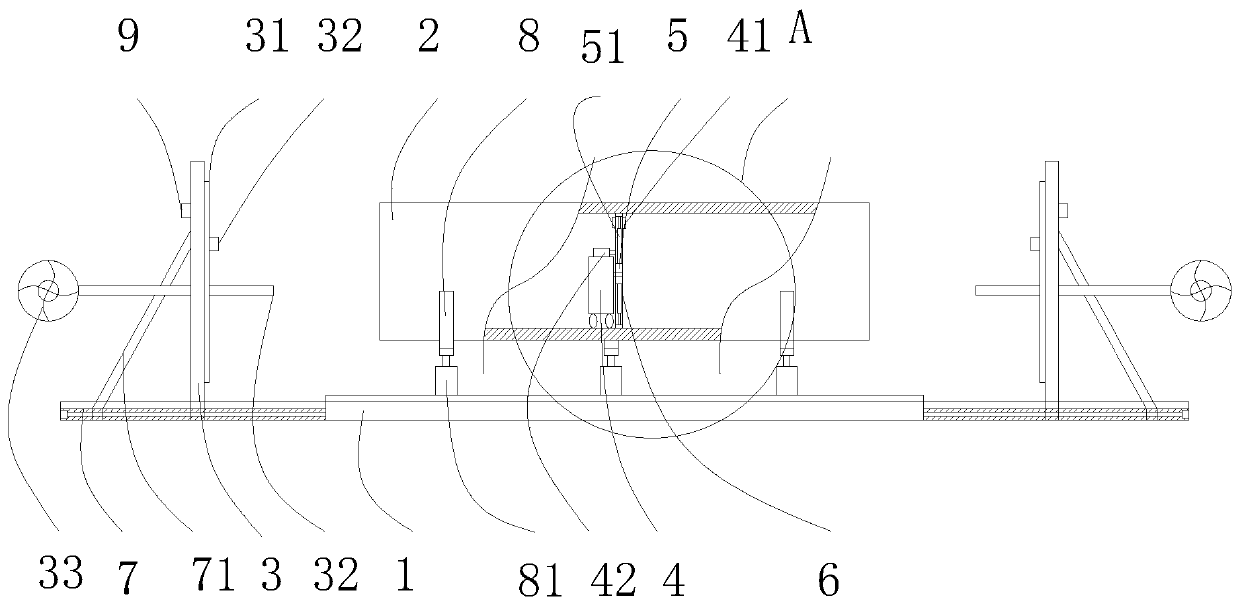

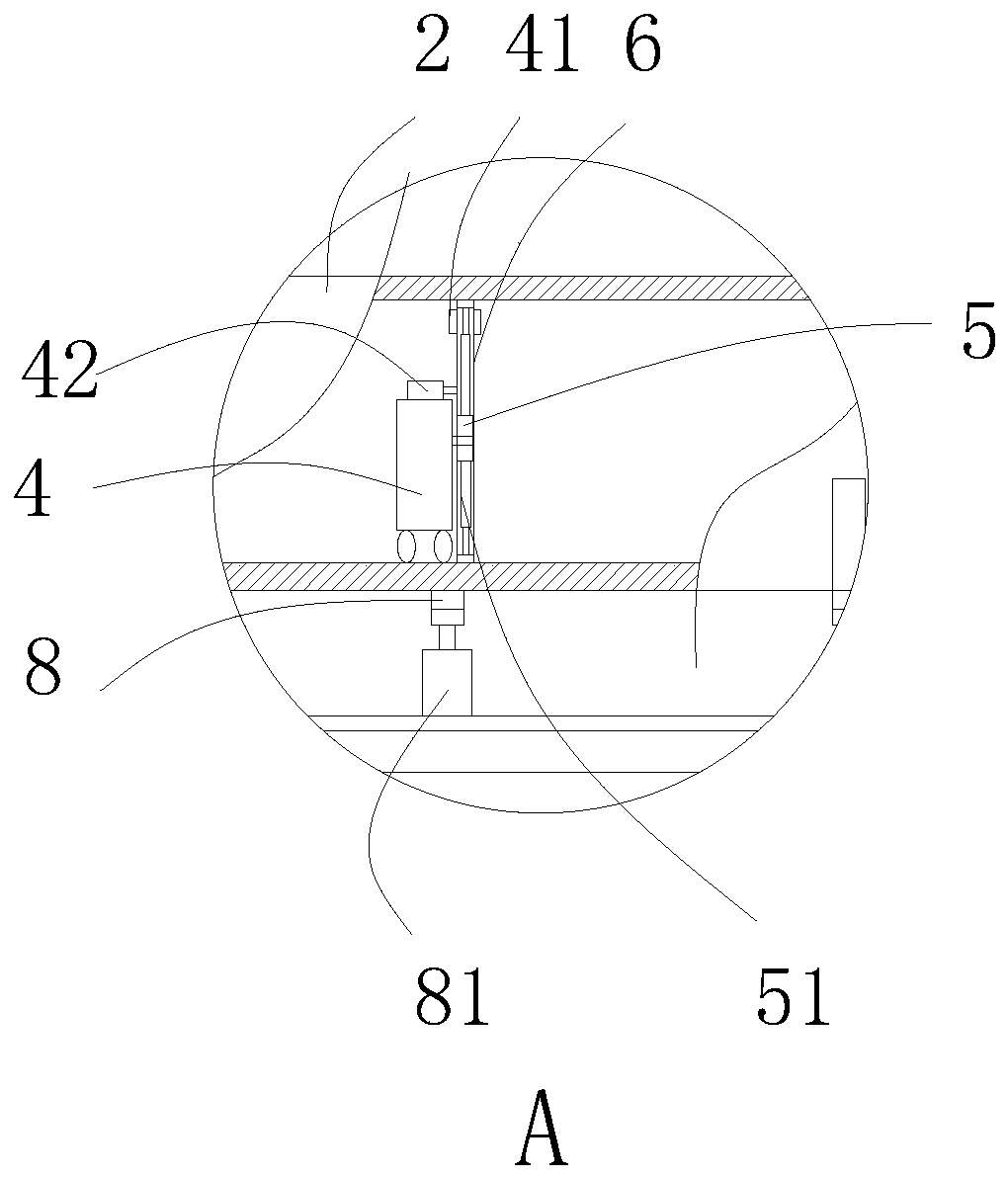

[0029] In specific implementation, such as Figure 1-Figure 2 As shown, a gas pipeline pipe wall defect detection device includes a base 1, and the base 1 is provided with at least two supports for supporting the gas pipeline 2 along its length direction, and the gas pipeline 2 is placed on the support On the seat; the two sides of the length direction of the base 1 are respectively provided with vertical boards 3, and the lower ends of the vertical boards 3 are respectively fixedly installed with moving mechanisms capable of driving them to move in the horizontal direction, and the opposite surfaces of the vertical boards 3 are respectively opposite to each other. A rubber pad 31 protrudes inward; a perforation is provided in the middle of the vertical plate 3, and a first air intake pipe 32 is fixedly installed in the perforation, and the outer end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com