Plug disc type steel rope joint for material conveying, application method and steel rope plug disc system for conveying

A plug-disc type and steel cable technology, which is applied in the direction of transmission elements or pulley ropes or cables, textile cables, belts/chains/gears, etc., can solve problems such as joint disconnection and insufficient connection strength, and meet design requirements. Good bearing capacity, simple and convenient connection operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings, but this description does not constitute any limitation to the present invention.

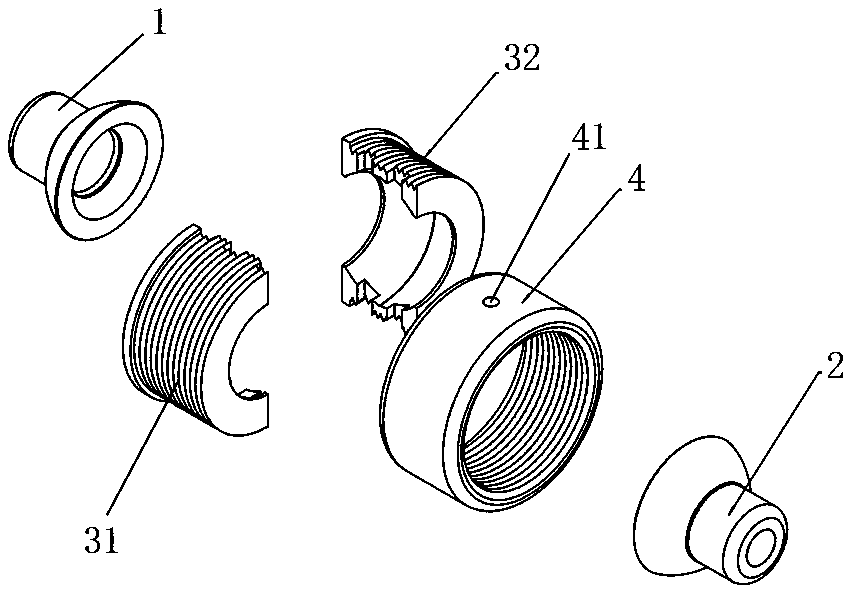

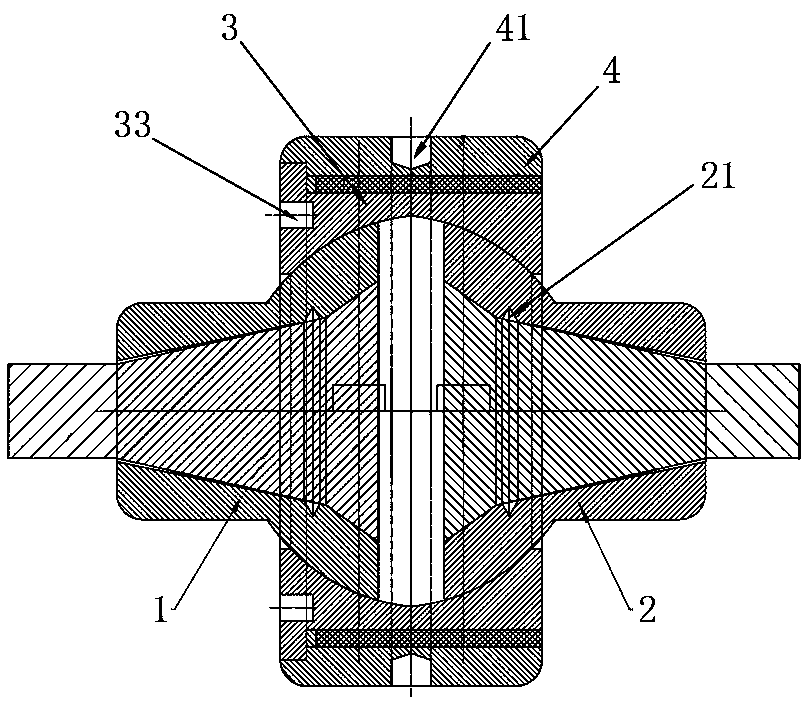

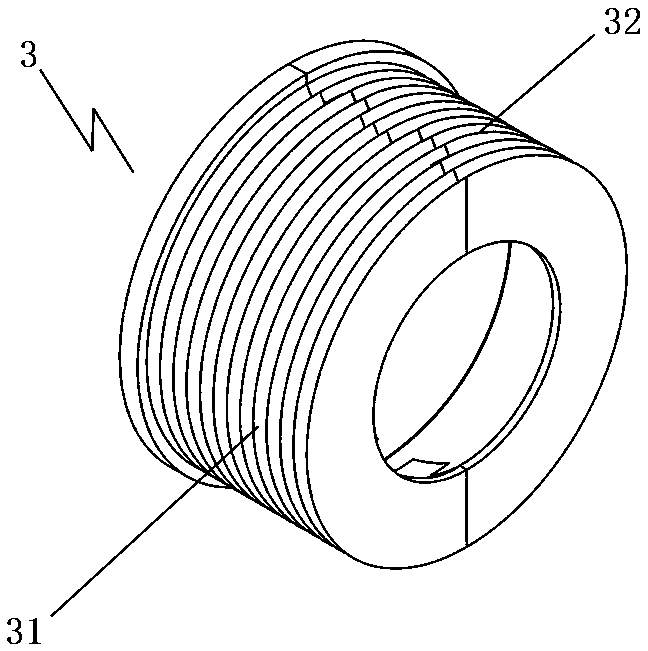

[0038] figure 1 , figure 2 , image 3 As shown, the plug-and-disk cable joint for transportation includes a left connecting part 1 , a right connecting part 2 , an inner ferrule 3 , a first petal body 31 , a second petal body 32 and an outer ferrule 4 .

[0039] Wherein, the left connecting part 1 is an axial member and is provided with a tapered inner cavity for passing through the steel cable. The outer peripheral surface of is a curved surface.

[0040] The right connecting part 2 is an axial part and is provided with a tapered inner cavity for passing through the steel cable. The face is a curved surface.

[0041] When the joint of the present invention is in use, the ends of the steel cables pass from the small end of the tapered inner cavity of the left connecting part and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com