Electric-gas hybrid type piston cylinder structure

A piston-cylinder, hybrid technology, used in electrical components, electromechanical devices, electric components, etc., can solve the problems of narrow application range, single feed form, low production efficiency, etc., and achieve a wide range of applications and various feed forms. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

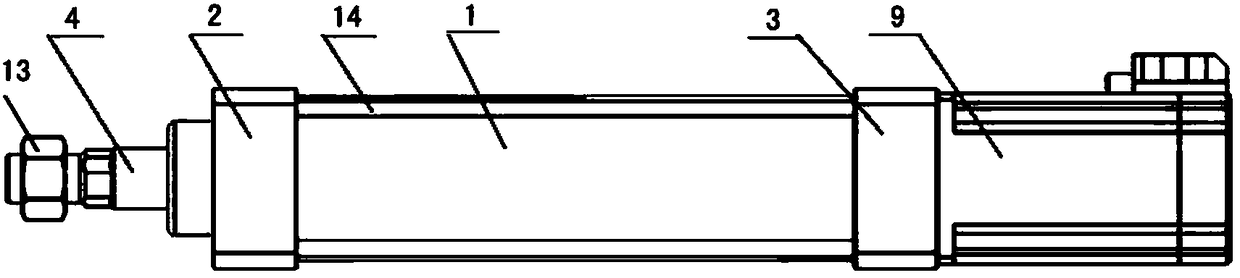

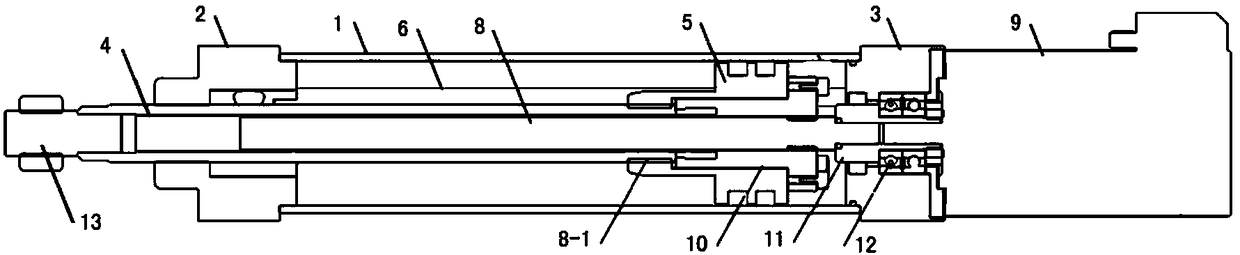

[0018] refer to figure 1 with figure 2 , the specific embodiment 1 comprises a cylinder block 1, a front end cover 2 and a rear end cover 3 are provided at the end of the cylinder block 1, a cylinder rod 4 and a cylinder piston 5 are provided in the inner chamber of the cylinder block 1, the front end cover 2 and the The rear end cover 3 seals the two ends of the cylinder body 1, the rear end of the cylinder rod 4 is fixedly connected with the cylinder piston 5, the front end of the cylinder rod 2 passes through the front end cover 2 and is exposed to form a connecting terminal 13, and the front end cover 2 and the The rear end caps 3 are each provided with an air inlet and outlet port and are connected to the inner cavity of the cylinder body 1 to form a gas piston cylinder structure; the cylinder rod 4 is a hollow rod body, and a ball screw 8 is arranged in the inner cavity of the cylinder rod 4, and at the rear end The outer side of the cover 3 is provided with a motor 9,...

specific Embodiment 2

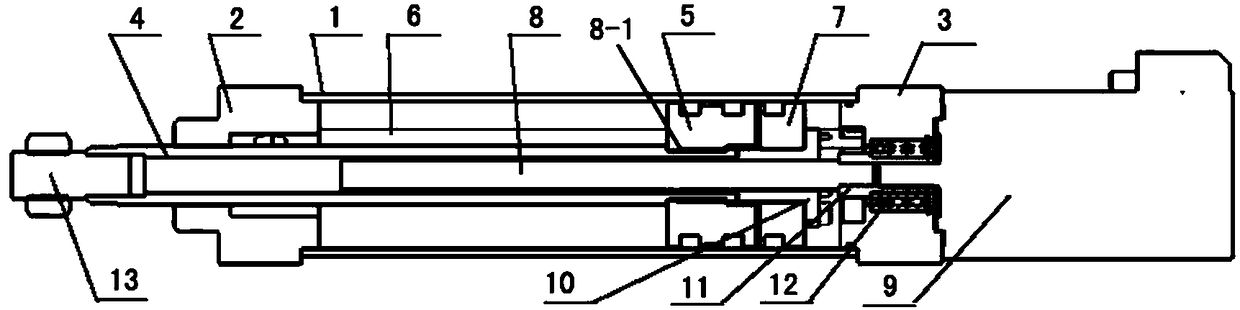

[0027] refer to figure 1 with image 3 , the characteristics of this specific embodiment 2 are: the screw nut 10 is provided with a nut fixed piston 7, an axial vent hole is arranged in the fixed piston 7, and an electric piston cylinder structure is formed through the axial vent hole in the fixed piston 7 . All the other are with specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com