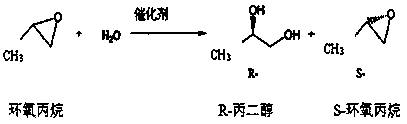

Method for reducing moisture content of byproduct S-epoxy propane in production of R-propylene carbonate

A technology of propylene carbonate and propylene oxide, applied in the direction of organic chemistry, can solve the problems of unfavorable energy saving and emission reduction, high production cost, high energy consumption, etc., and achieve the effects of easy control, low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

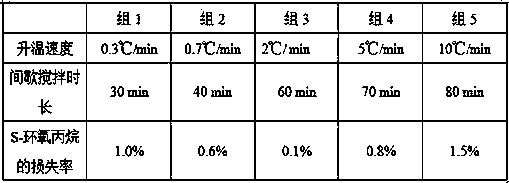

Examples

Embodiment 1

[0025] Embodiment 1 A kind of method that reduces R-propylene carbonate production by-product S-propylene oxide moisture content

[0026] Add 50kg of caustic soda (sodium hydroxide) to a 5000L glass-lined still with agitation, add 3000kg of R-propylene carbonate production by-product S-propylene oxide before treatment, and add at a rate of 200kg / min at one time. Turn on the stirring, the stirring speed is 85r / min, stir for 60 minutes, then distill with 50-65°C circulating hot water, the circulating hot water flow rate is 200kg / min, the heating time is 30-50 minutes, the fraction recovered by cooling is to reduce the moisture content of the by-product S-propylene oxide.

[0027] The moisture content of the by-product S-propylene oxide before treatment: 1.02%, and the moisture content of the by-product S-propylene oxide after treatment: 0.24%, which meets the customer’s S-propylene oxide quality standard.

[0028] The mass ratio of caustic soda: S-propylene oxide is 1.67:100. ...

Embodiment 2

[0030] Embodiment 2 A kind of method that reduces R-propylene carbonate production by-product S-propylene oxide moisture content

[0031] Add 75kg of caustic soda (sodium hydroxide) to a 5000L glass-lined still with agitation, add 3000kg of R-propylene carbonate production by-product S-propylene oxide before treatment, and add at a rate of 200kg / min at one time. Turn on the stirring, the stirring speed is 85r / min, stir for 90 minutes, then distill with 50-65℃ circulating hot water, the circulating hot water flow rate is 200kg / min, the heating time is 30-50 minutes, the fraction recovered by cooling is to reduce the moisture content of the by-product S-propylene oxide.

[0032] The moisture content of the by-product S-propylene oxide before treatment: 1.52%, and the moisture content of the by-product S-propylene oxide after treatment: 0.34%, which meets the customer’s S-propylene oxide quality standard.

[0033] The mass ratio of caustic soda: S-propylene oxide is 2.50:100.

...

Embodiment 3

[0035] Embodiment 3 A kind of method that reduces R-propylene carbonate production by-product S-propylene oxide moisture content

[0036] Add 21kg of caustic soda (sodium hydroxide) to a 5000L glass-lined still with agitation, add 3000kg of R-propylene carbonate production by-product S-propylene oxide before treatment, and add at a rate of 200kg / min at one time. Turn on the stirring, the stirring speed is 85r / min, stir for 30 minutes, then distill with 50-65°C circulating hot water, the circulating hot water flow rate is 200kg / min, the heating time is 30-50 minutes, the fraction recovered by cooling is to reduce the moisture content of the by-product S-propylene oxide.

[0037] The moisture content of the by-product S-propylene oxide before treatment: 0.61%, and the moisture content of the by-product S-propylene oxide after treatment: 0.29%, which meets the customer’s S-propylene oxide quality standard.

[0038] The mass ratio of caustic soda: S-propylene oxide is 0.70:100. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com