A device for combining warp printing and sizing

A warp and printing technology, used in printing, printing presses, rotary printing presses, etc., can solve the problems of quality decline and printing effect, reduce energy consumption, improve warp printing effect and color fastness, and have rich layering of fabrics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

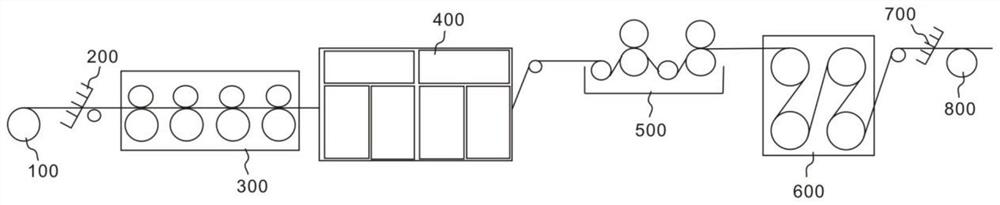

[0044] Such as figure 1 Shown is the overall schematic diagram of the equipment. In this embodiment, in order to realize the warp yarn printing before the sizing process, the simultaneous production of warp yarn printing and sizing is realized, the printing effect and color fastness are improved, and the coloring effect is good. Therefore, the main processes in the weaving process flow include winding process, warping process, printing process, color fixing process and sizing process, and the corresponding process equipment includes unwinding device 100, front expansion reed 200, printing device 300, Baking device 400, sizing device 500, drying device 700, splitting reed 700 and winding device 800, wherein the unwinding device 100 is used for winding the original warp yarn to carry out beam warping; the printing device 300 is arranged on the unwinding device Winding the rear end of the device 100, and the warp yarn output of the unwinding device 100 adjusts the width of the or...

Embodiment 2

[0047] Based on the process equipment in the first embodiment, that is, a device for combining warp yarn printing and sizing, a method for sizing warp yarns for printing is also provided in this embodiment based on the device, and the method includes the following steps,

[0048] S1: After the original warp yarn is output by the unwinding device 100, the width of the warp yarn layer is adjusted through the front telescopic reed 200 to match the parameters of the printing device 300;

[0049] S2: Input the adjusted original warp yarns into the cylinder of the printing device 300 to perform printing operation on the original warp yarns to produce printed warp yarns;

[0050] S3: the printed warp yarn is transferred to the baking device 400 for color fixation, which can improve the printing effect and color fastness;

[0051] S4: The warp yarn after the color fixing operation is input into the sizing device 500 for sizing the warp yarn, and then input into the drying device 700 t...

Embodiment 3

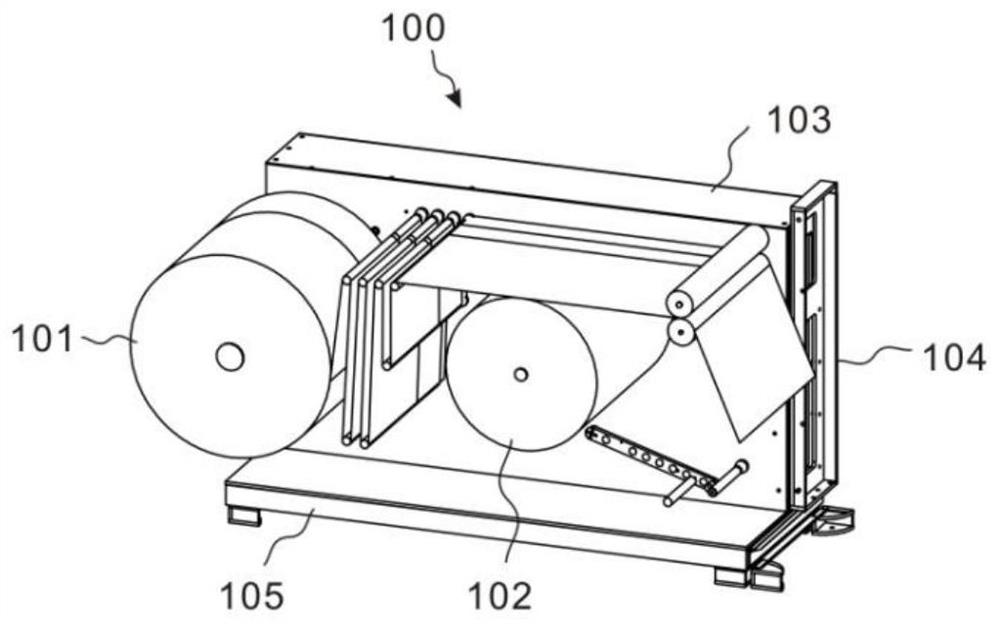

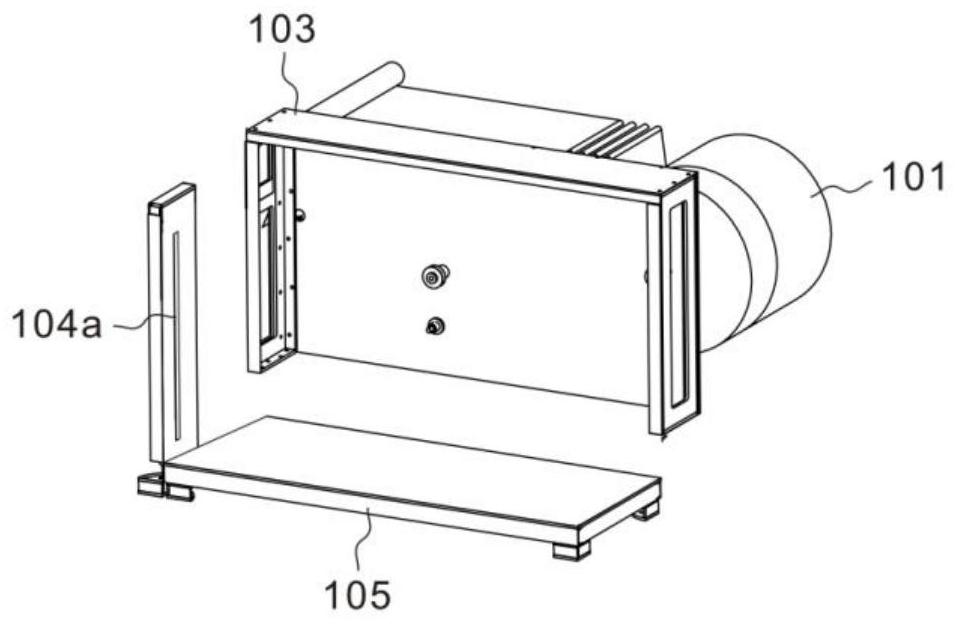

[0086] refer to Figure 2-4 Shown is an unwinding device 100 provided in this embodiment. In this embodiment, in order to realize the lifting between the unwinding device 100 and the subsequent process, so as to adjust the tightness of the warp yarn when the unwinding device 100 is output, it is simple In other words, the height of the equipment in the subsequent process is constant, but by changing the height of the unwinding device 100, the distance between the unwinding device 100 and the subsequent process can be changed, thereby controlling the tightness of the output warp yarn. The unwinding device 100 also includes a front driving roller 101 , a rear driving roller 102 , a lifting vertical plate 103 , a lifting side plate 104 and a base 105 . Specifically, the front driving roller 101 and the rear driving roller 102 are arranged on one side of the lifting riser 103 for warp delivery, and the edge side of the lifting riser 103 and one side end of the lifting side plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com