A Multi-Cylinder Synchronous Control Method

A control method and controller technology, which is applied in the field of forging and pressing manufacturing, can solve problems such as difficulty in realization, difficulty in meeting precision requirements of control methods, complexity, etc., and achieve the effect of simple control structure, obvious practical application value, and easy debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

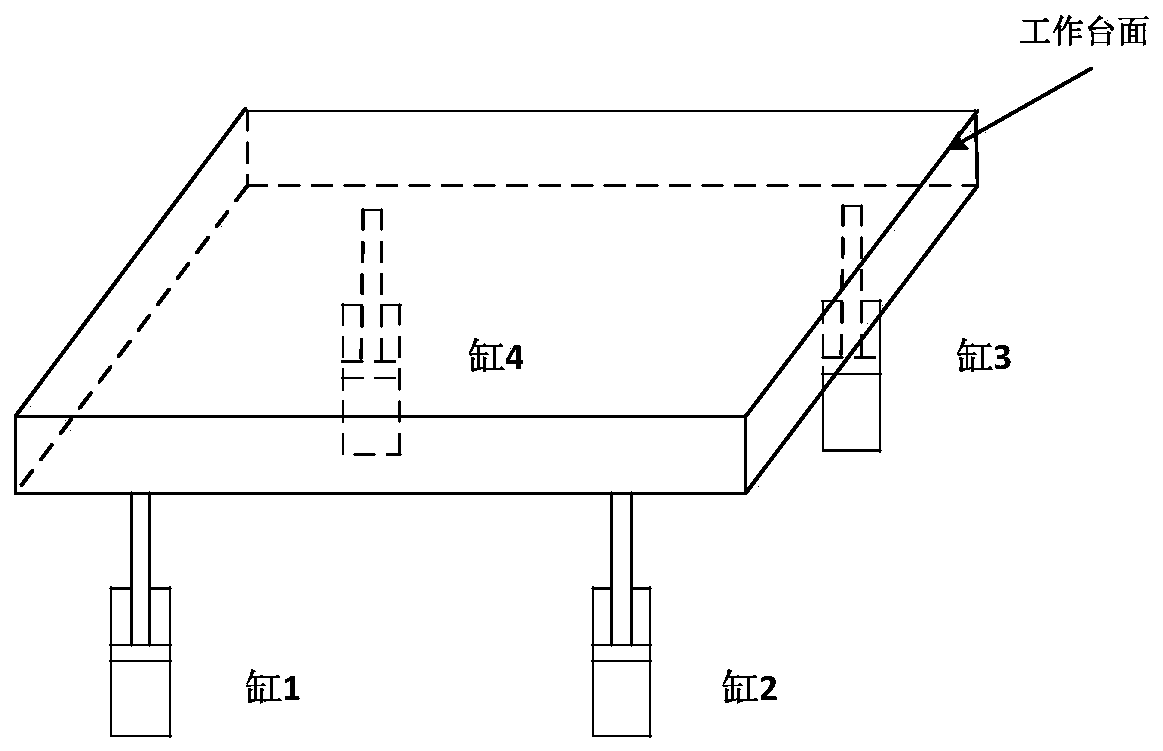

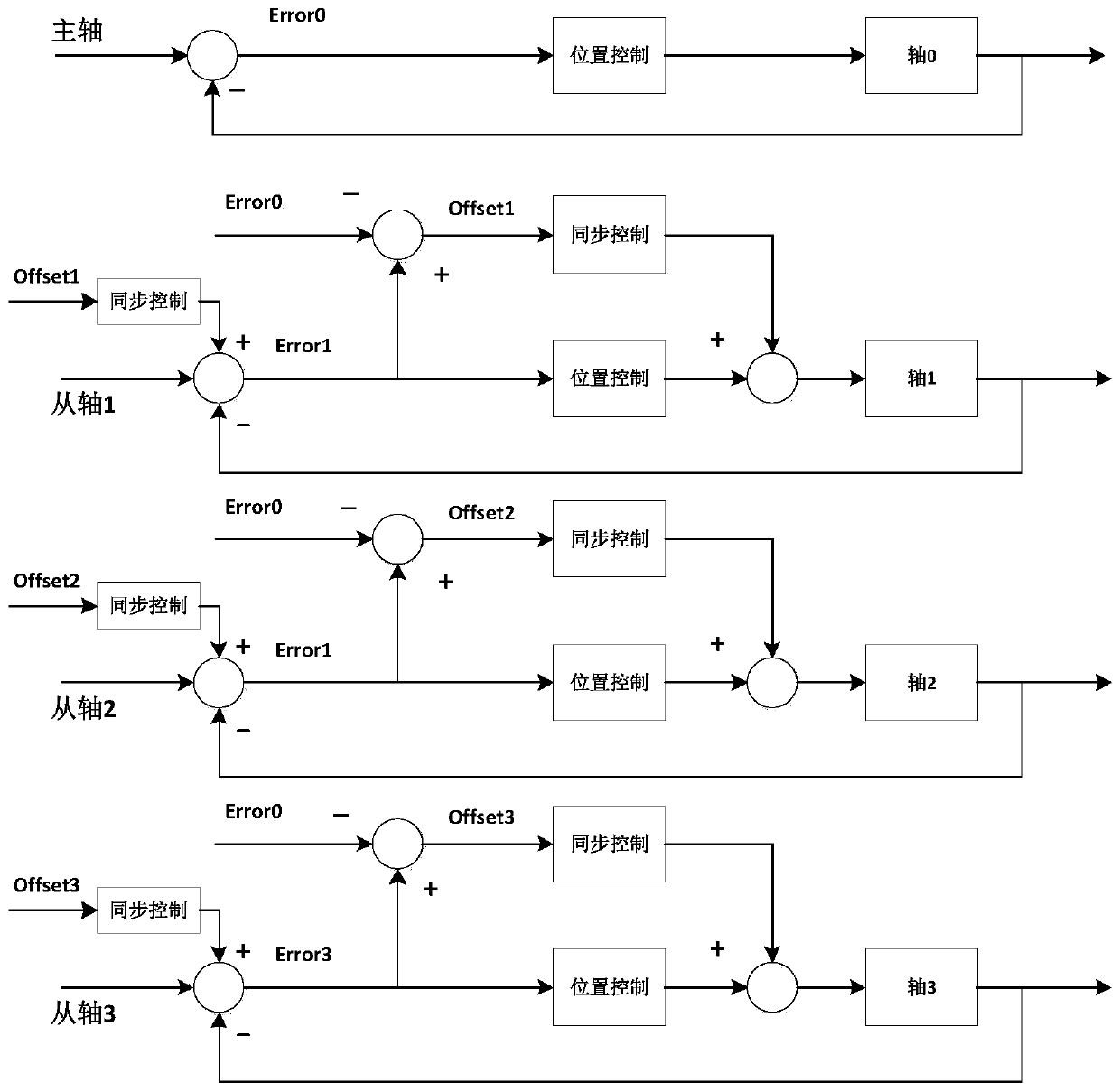

[0024] The present invention proposes a master-slave synchronization control method with self-adjustment of the main shaft, which is used in a multi-cylinder synchronization system, where the shaft is a hydraulic cylinder. The present invention optimizes the traditional master-slave synchronization control and avoids the disadvantages of the slave shaft lagging behind the main shaft. The optimal tracking axis is selected in real time as the current master axis, and the master axis's synchronous adjustment of each slave axis ensures excellent synchronization performance without affecting the tracking performance of each axis. The invention has a simple control structure, is easy to debug, and has obvious engineering application value.

[0025] The specific implementation steps of the present invention are as follows:

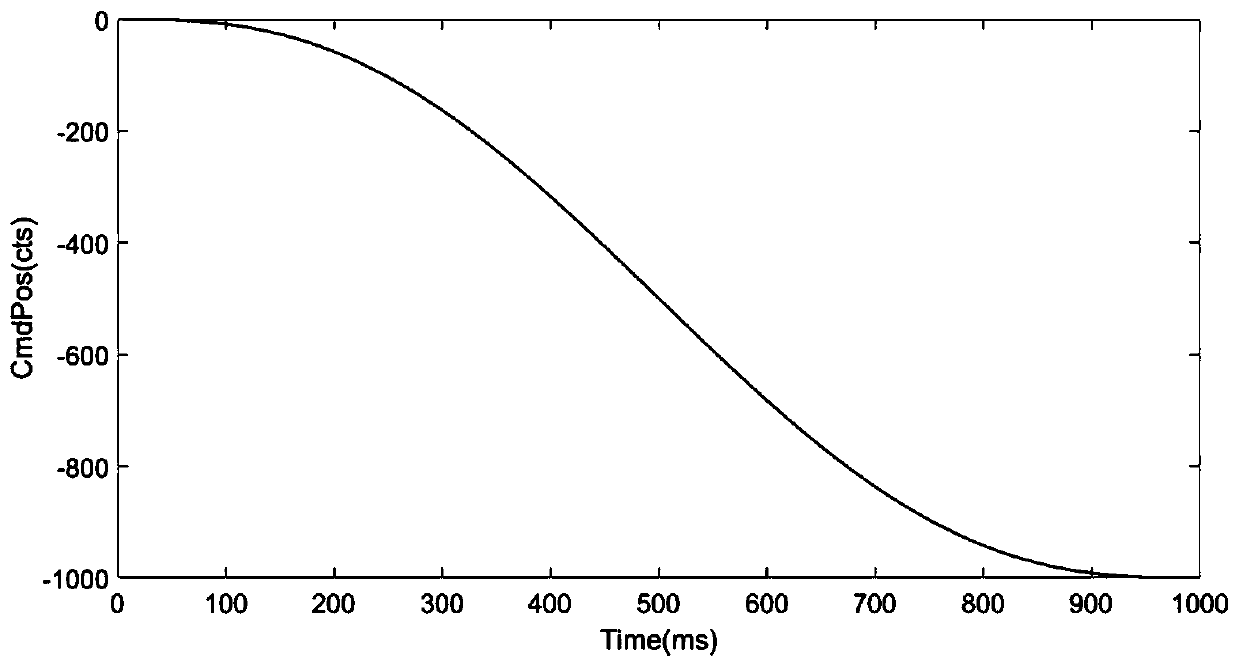

[0026] a) According to the process requirements, plan the curve of each axis and generate the position command CmdPos(i), where i is the axis number of each axis;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com