A kind of cloth printing and dyeing processing equipment

A technology for processing equipment and fabrics, applied in the field of textile printing and dyeing, can solve the problems of detecting whether the chromaticity of the fabric meets the standard, the chromaticity of the fabric has a great influence, and it is inconvenient to judge the fabric. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

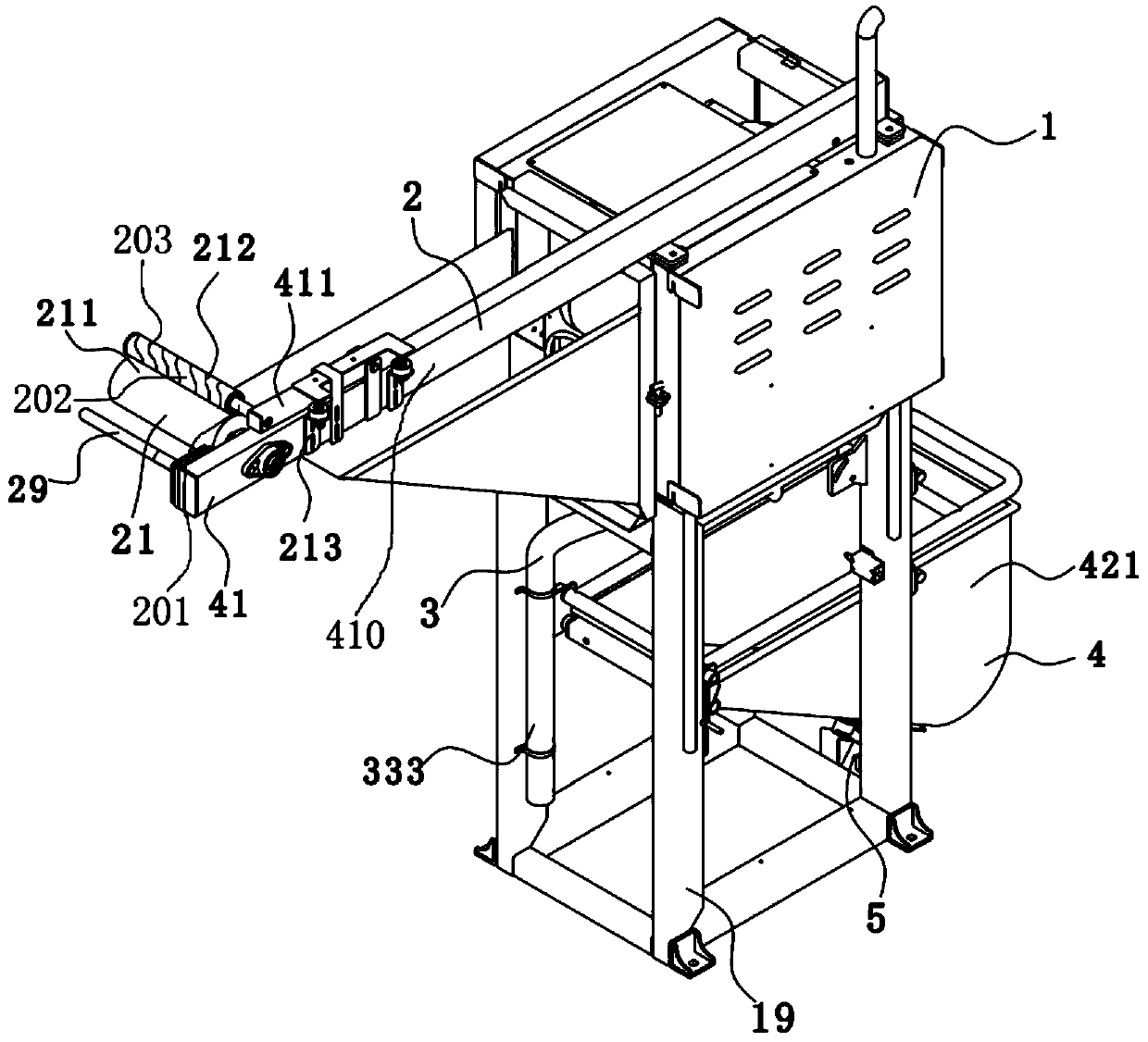

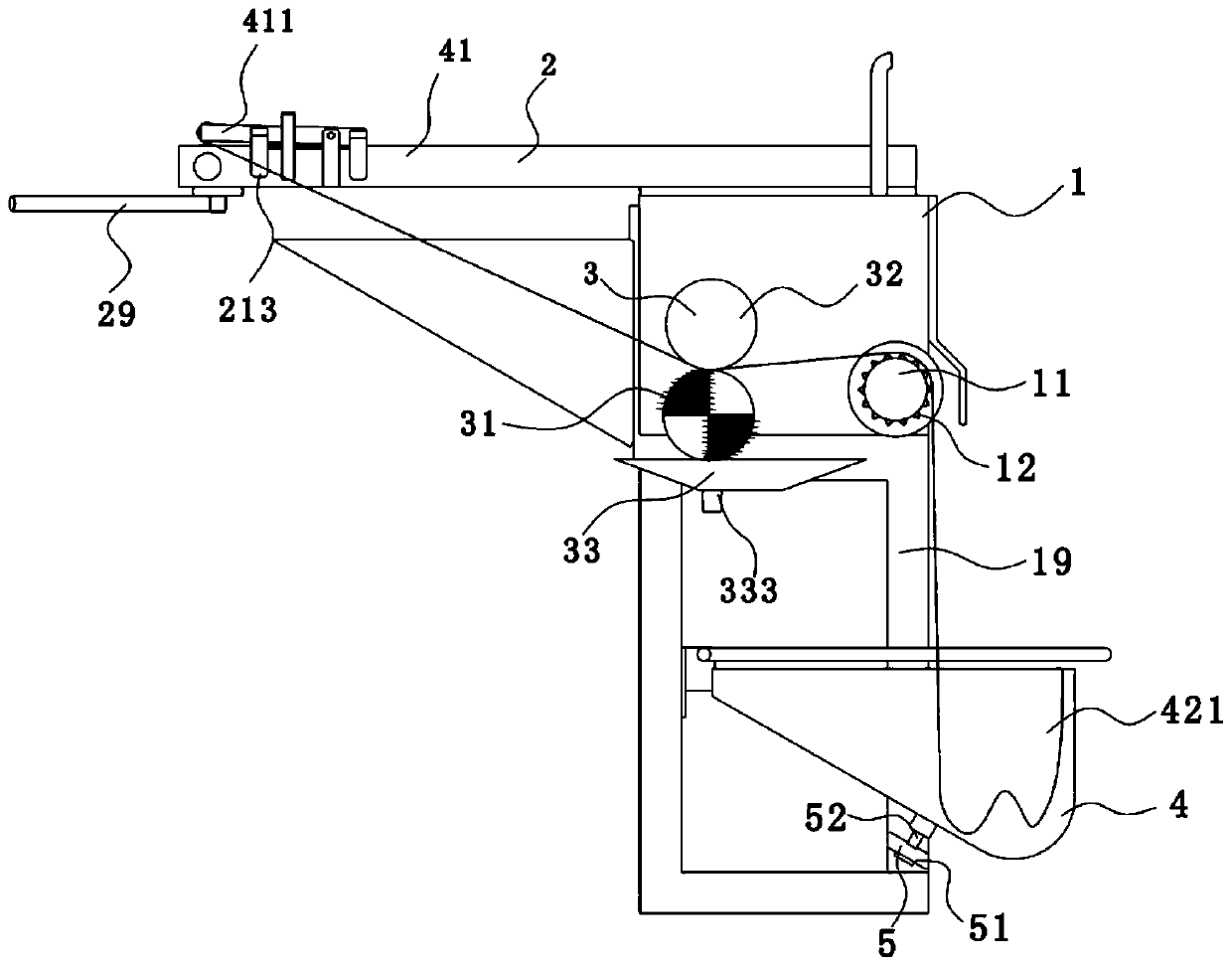

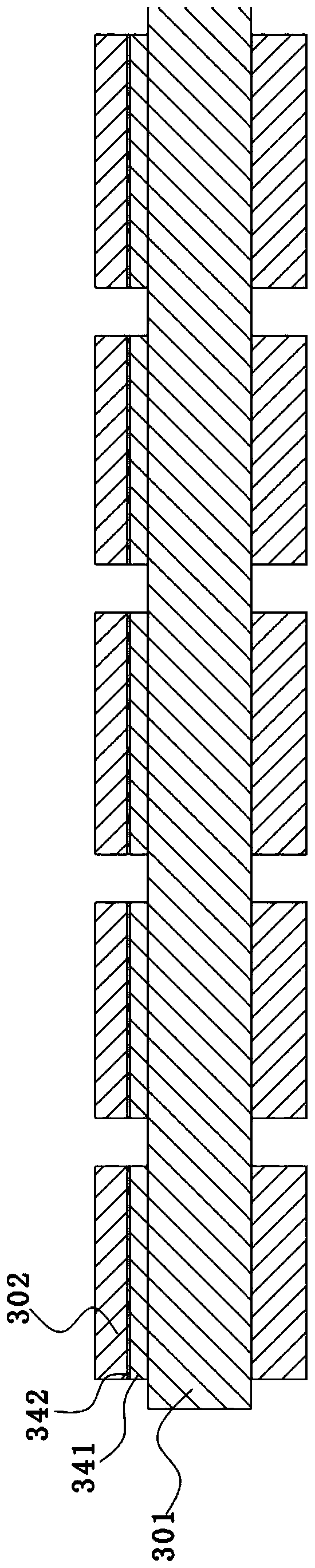

[0018] Such as Figure 1-4 As shown, a cloth printing and dyeing processing equipment includes a support frame 1, a detection mechanism 2, a pressure roller mechanism 3 and a cloth bucket mechanism 4; wherein the support frame 1 is a metal frame with four support columns 19; The detection mechanism 2, the pressure roller mechanism 3 and the cloth bucket mechanism 4 are all arranged on the support frame 1; specifically, the detection mechanism 2 includes a cloth support assembly 41, a cloth feeding assembly 21 and a limiter 29; the cloth support The assembly 41 includes a cloth spreader body 410, a movable part 411 and a detection device 213. The cloth spreader body 410 is a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com