Concrete test piece forming die capable of adjusting steel bar position and forming method

A technology for the location of concrete specimens and steel bars, which is applied to molds, ceramic molding machines, mold fixing devices, etc., and can solve problems such as difficult fixing of long side plates and unstable fixing of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] Such as Figure 1-9 As shown, the embodiment of the present invention provides a concrete specimen forming mold capable of adjusting the position of steel bars, including a bottom plate 2, two opposite side plates 1 and two opposite end plates 7, the side plates 1 and the end plate 7 are fixed around the bottom plate 2, so that the side plate 1, the end plate 7 and the bottom plate 2 enclose a cavity with an open top for forming a concrete specimen,

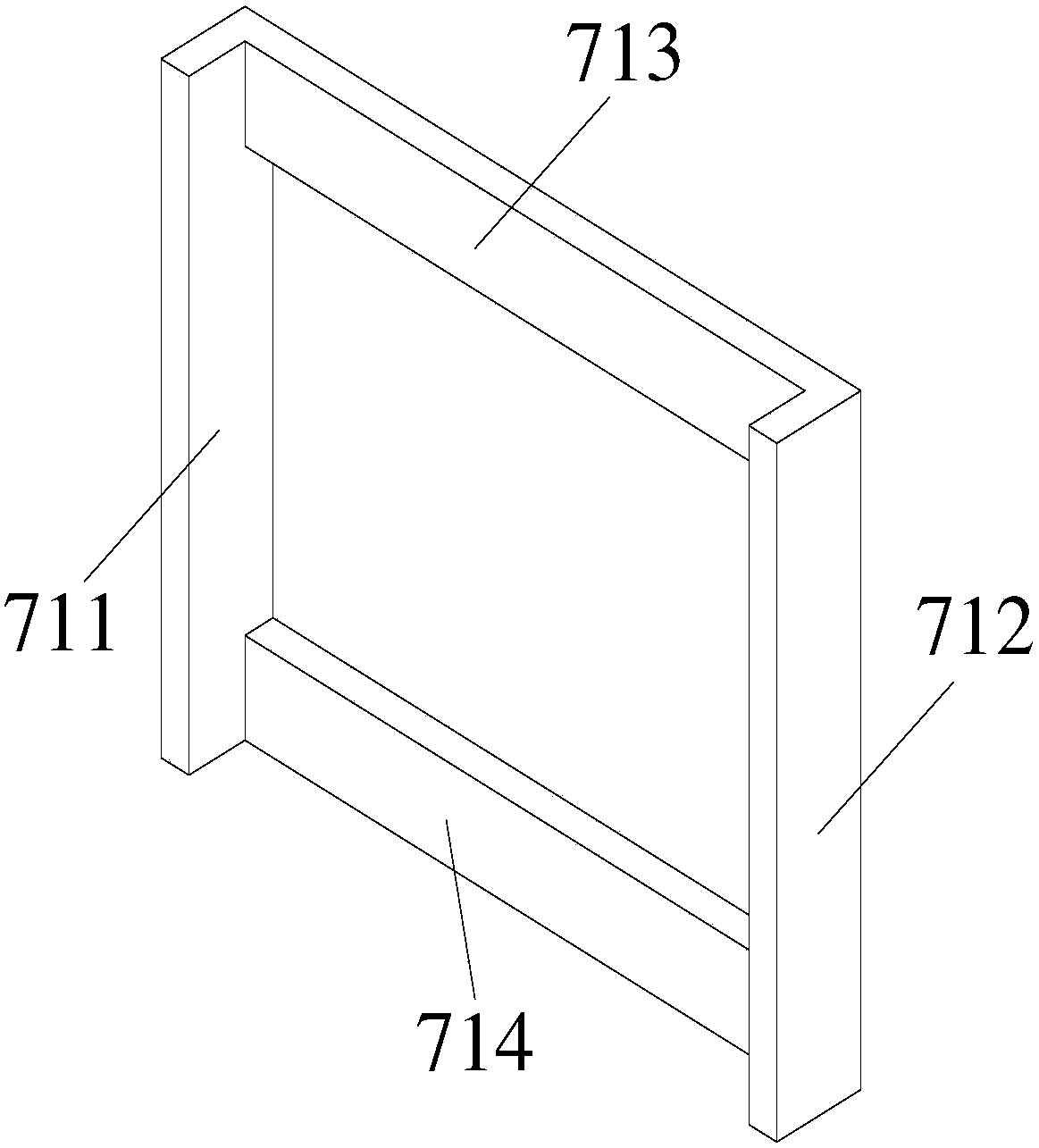

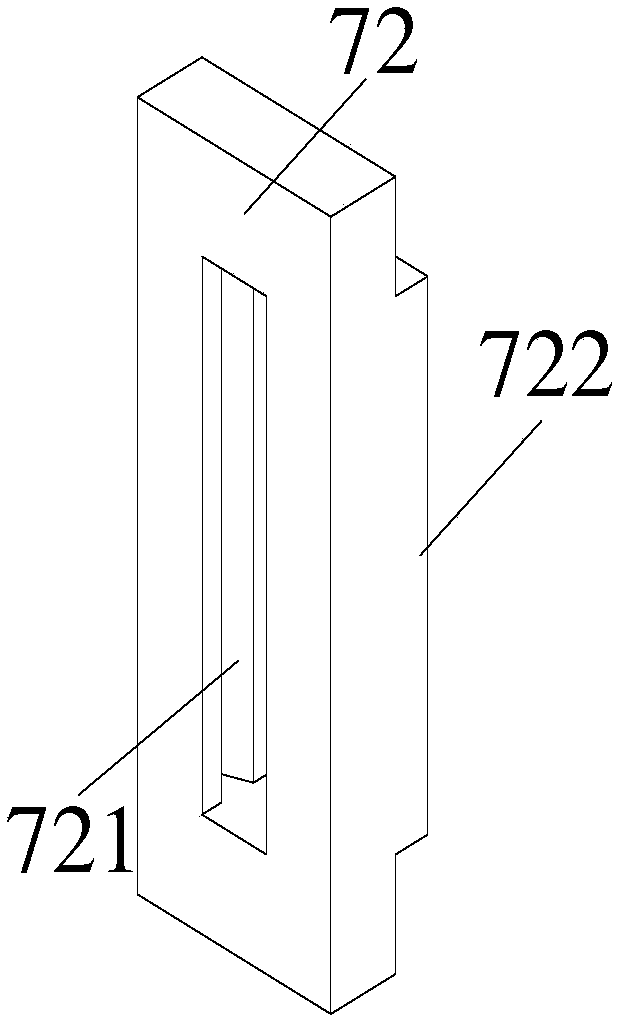

[0084] The end plate 7 includes an end plate support 71 and a T-shaped adjustment area, and the end plate support 71 is composed of an upper frame 713 extending along the X-axis direction, a lower frame 714 and a left frame 711 extending along the Y-axis direction 1. The right frame 712 encloses a structure with a cavity in the middle. The T-shaped adjustment area includes an adjustment area base 81 and an adjustment area boss 82 protruding from one side of the adjustment area base 81. The adjustment area boss 82 insertin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com