Fine separation module of oil-gas separator

An oil-gas separator and fine separation technology, which is applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of large pressure difference changes in the oil-gas separator, adjustment, and influence on the oil-gas separation effect of the oil-gas separator, and achieve reduction Changes in pressure difference, the effect of improving the effect of oil and gas separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

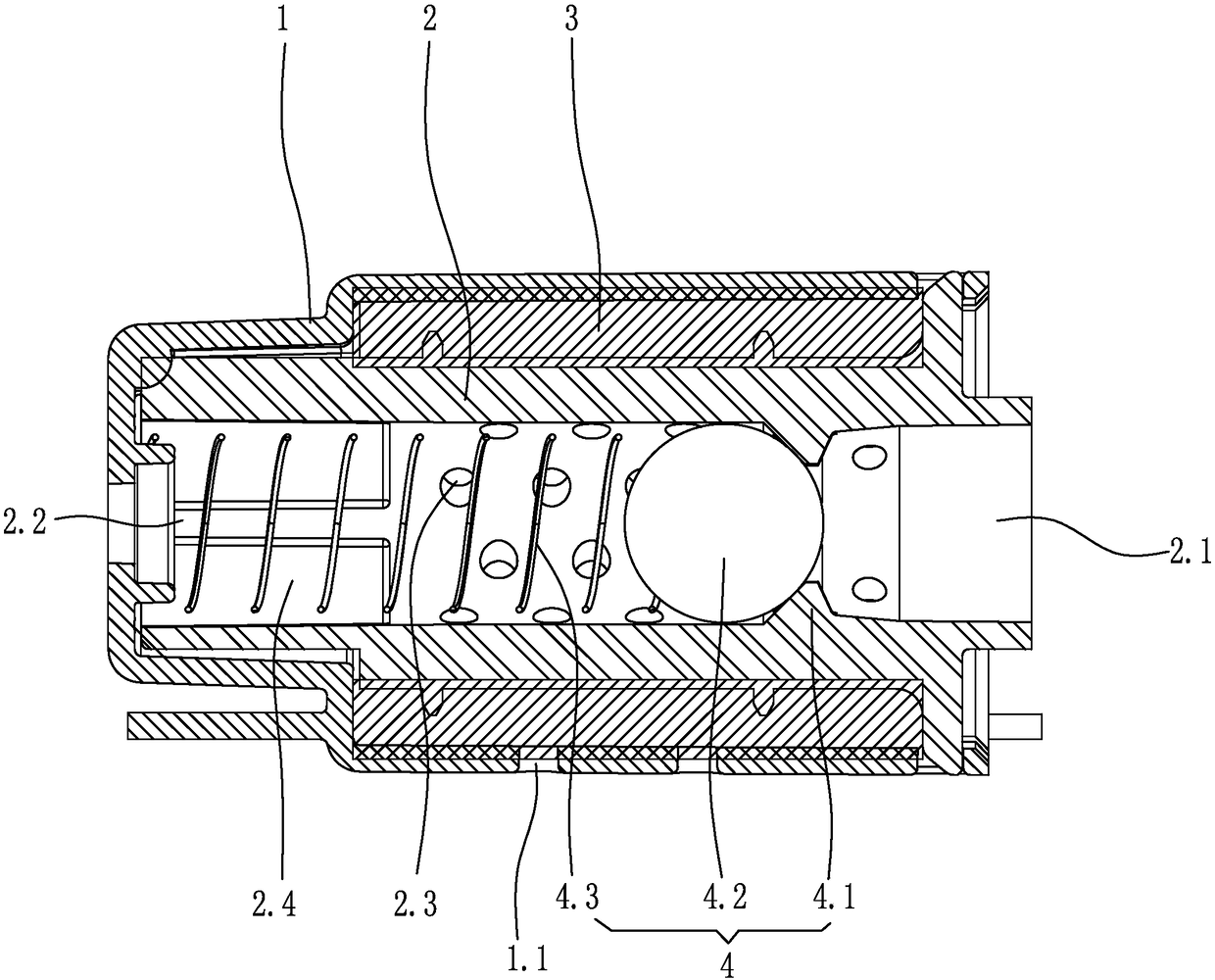

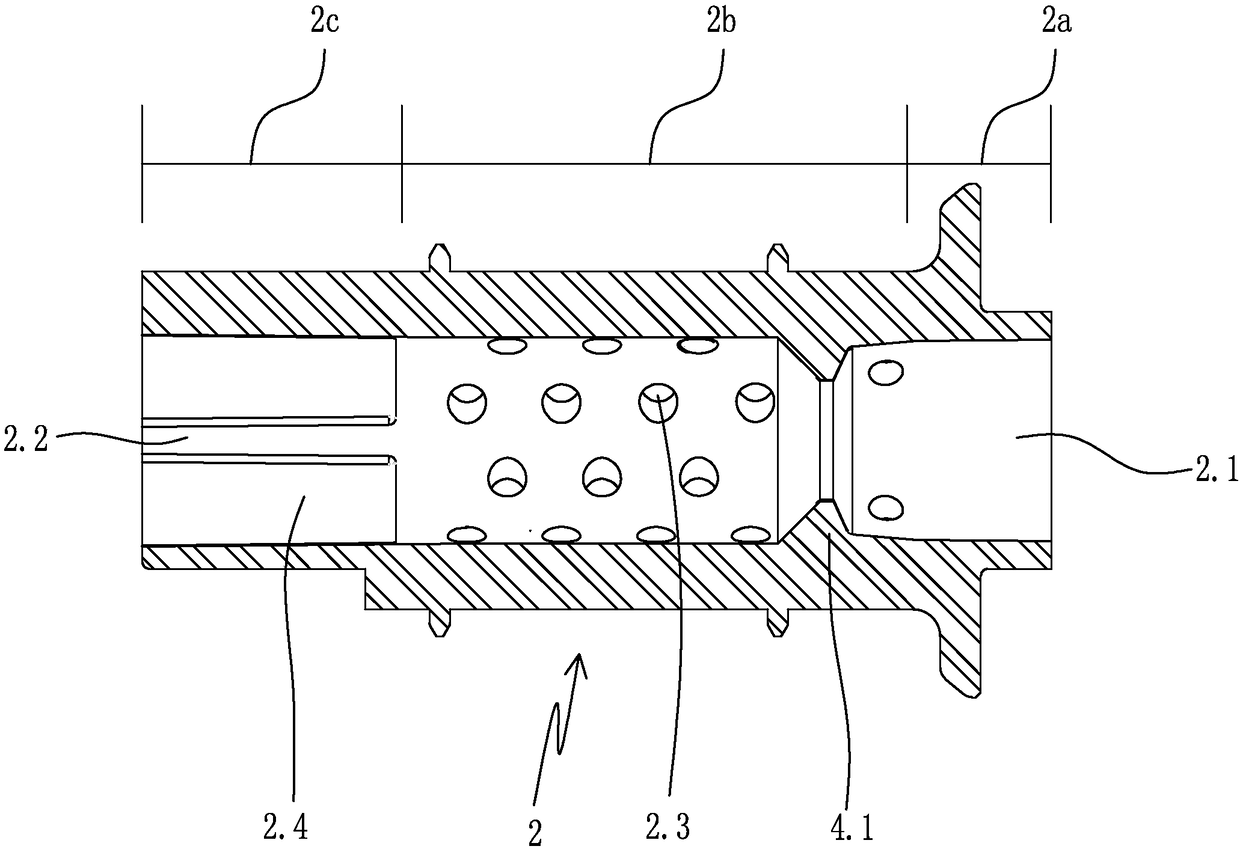

[0027] Such as figure 1 As shown, a fine separation module of an oil-gas separator includes a fine separation shell 1, a fine separation pipeline 2 arranged in the fine separation shell, a fine separation cotton layer 3 positioned between the fine separation shell and the fine separation pipeline, and a fine separation cotton layer arranged in the fine separation shell. The self-adaptive pressure difference adjustment mechanism 4 in the separation pipeline.

[0028] The fine separation shell is a plastic shell. The lower part of the outer surface of the fine separation shell is provided with an oil return hole 1.1. The fine separation pipe is a plastic pipe. The fine separation shell and the fine separation pipeline are connected by a buckle. Several protrusions are arranged on the outer surface of the fine separation pipe.

[0029] The fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com