Method for producing natural stone flexible materials

A technology of flexible materials and production methods, applied in covering/lining, construction, building construction, etc., can solve the problems of low labor productivity, inability to use modern technology for mass production, and high technical requirements, and achieve the effect of large space and possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with embodiment the method of the present invention is described in further detail. It should be noted that the protection scope of the present invention shall include but not be limited to the technical content disclosed in this embodiment.

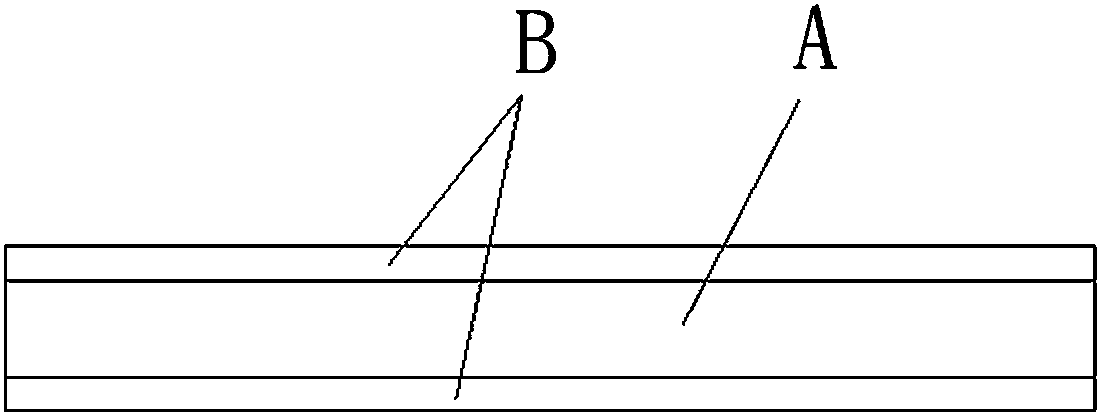

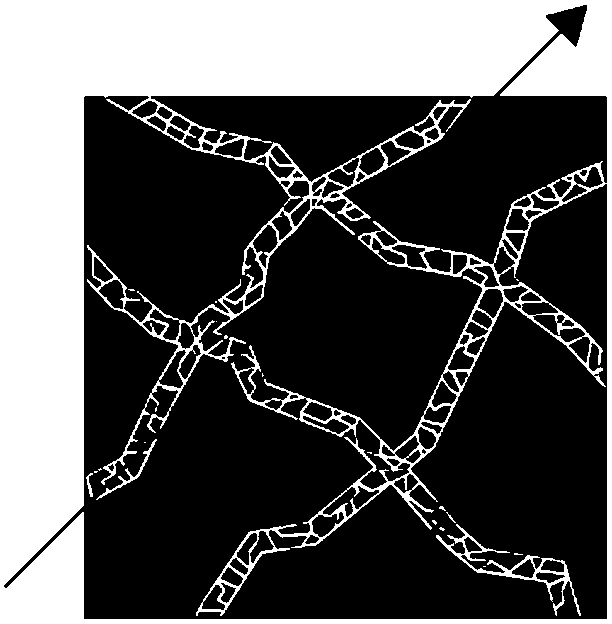

[0035] In the production method of the natural stone flexible material of the present invention, a polymer material layer B is coated on both sides of the natural stone plate layer A, at least one of the two polymer material layers B is transparent to show the natural texture of the stone Pattern; composite material coated with layers of polymeric material treated to form curved surfaces.

[0036] Specific steps are as follows:

[0037] 1) Preparation of natural stone slabs, cutting the marble into sheets or slices with a thickness of 0.3-20 mm;

[0038] 2) Coat the front and back of the natural stone slab B with polymer materials, such as modified epoxy resin, TPR, TPE or silicone rubber and other elastic m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com