Composite textile finishing agent as well as preparation method and application thereof

A technology of textile finishing and composite materials, applied in textiles and papermaking, fiber treatment, plant fibers, etc., can solve the problems of not being able to guarantee the uniformity of materials, affecting the strength of fibers, and the inapplicability of natural fibers, etc., to achieve simple production and low cost , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

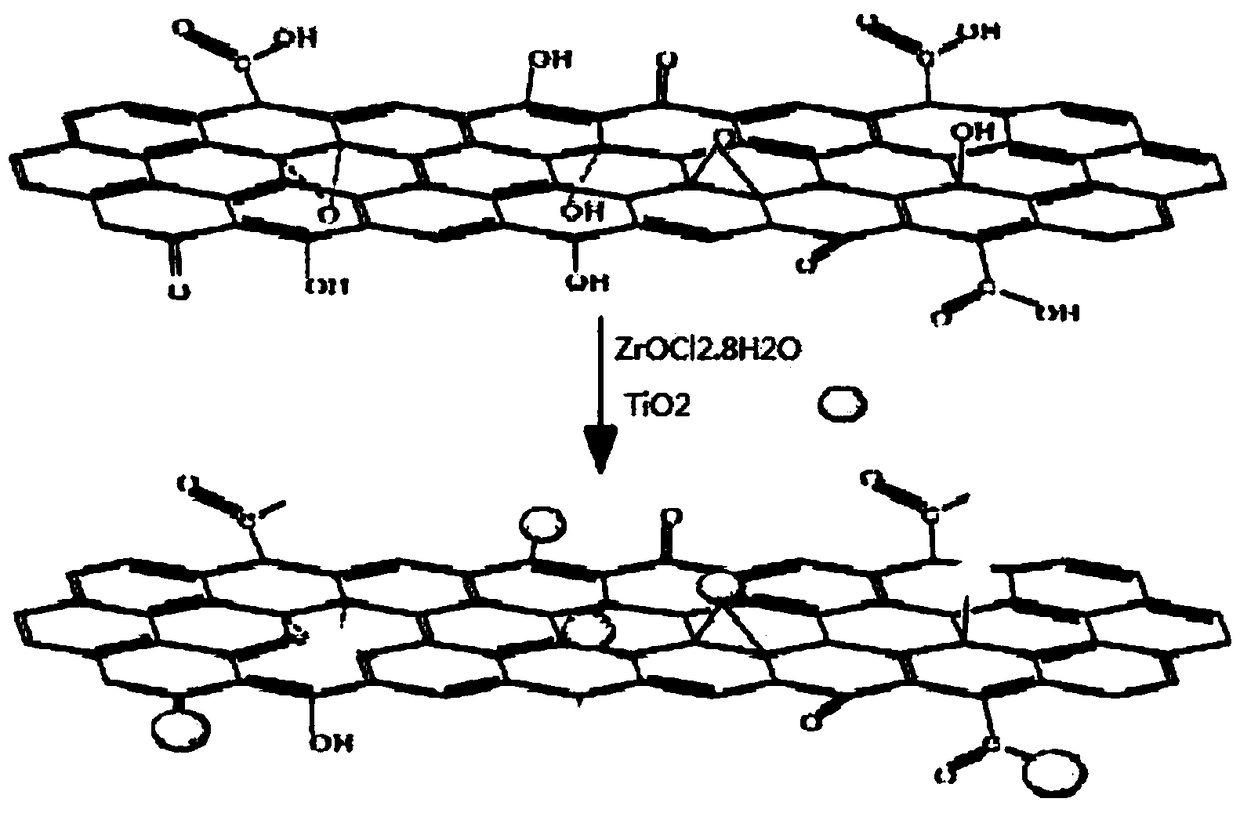

[0037] (1) Using natural graphite powder as raw material, reacting with concentrated sulfuric acid and potassium permanganate, adopting Hummers oxidation method, after filtration, centrifugal washing and vacuum drying, the graphene oxide nanosheets with a thickness of about 15nm are prepared.

[0038] (2) Take 0.2 g of the graphene oxide nanosheets prepared in step (1), add it into water, and ultrasonicate for 1 hour with a power of 180 W to prepare a graphene oxide suspension.

[0039] (3) Add 0.4 g of zirconium oxychloride to the graphene oxide suspension prepared in step (2), and process it by ultrasonic treatment for 0.5 h with a power of 450 W, then add 0.4 g of titanium dioxide nanopowder, and stir for 1 h. The obtained mixed solution was subjected to high-temperature hydrothermal reaction, the reaction time was 8 hours, the reaction temperature was 120° C., centrifuged and dried to obtain a graphene oxide / titanium dioxide / zirconia composite material.

[0040] (4) Add th...

Embodiment 2

[0046] (1) Using natural graphite powder as raw material, reacting with concentrated sulfuric acid and potassium permanganate, adopting Hummers oxidation method, after filtration, centrifugal washing and vacuum drying, the graphene oxide nanosheets with a thickness of about 15nm are prepared.

[0047] (2) Take 0.4 g of graphene oxide nanosheets prepared in step (1), add them into water, and ultrasonicate for 1 hour with a power of 180 W to prepare a graphene oxide suspension.

[0048] (3) 0.3 g of zirconium oxychloride is added in the graphene oxide suspension prepared in step (2), and treated by ultrasonic treatment, the ultrasonic time is 0.5 h, and the power is 450 W, then 0.3 g of titanium dioxide nanopowder is added, stirred for 1 h, The obtained mixed solution was subjected to high-temperature hydrothermal reaction, the reaction time was 8 hours, the reaction temperature was 120° C., centrifuged and dried to obtain a graphene oxide / titanium dioxide / zirconia composite mate...

Embodiment 3-5

[0053] The influence test of embodiment 3-5 component content on the far-infrared emissivity of material

[0054] In order to confirm the effect of the proportion of each component in the material on the far-infrared emissivity of cotton fabrics, and to seek the optimal proportion, we made composite materials with different proportions of graphene oxide content, and the weight ratio is graphene oxide / titanium dioxide / Zirconium oxychloride 6:2:2 (embodiment 3), 8:1:1 (embodiment 4), 10:0:0 (embodiment 5), respectively replace the weight ratio of three kinds of materials feeding and implement as mentioned above The method of Example 1 or 2 was carried out, whereby Examples 3-5 were obtained. The result is as Figure 4 shown. Among them, for the blank group, it is a blank control test of untreated pure cotton double-sided knitted fabric, and its far-infrared emission rate is 86.7%, which is basically consistent with that reported in the literature. When graphene oxide / titania...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com