Mounting and tensioning device of filtration fabric for electroosmosis sludge high-dryness dewatering machine

A tensioning device and electro-osmosis technology, which is applied in electrochemical sludge treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of easy wrinkling of filter cloth, loose fastening, inconvenient assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] For ease of understanding, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

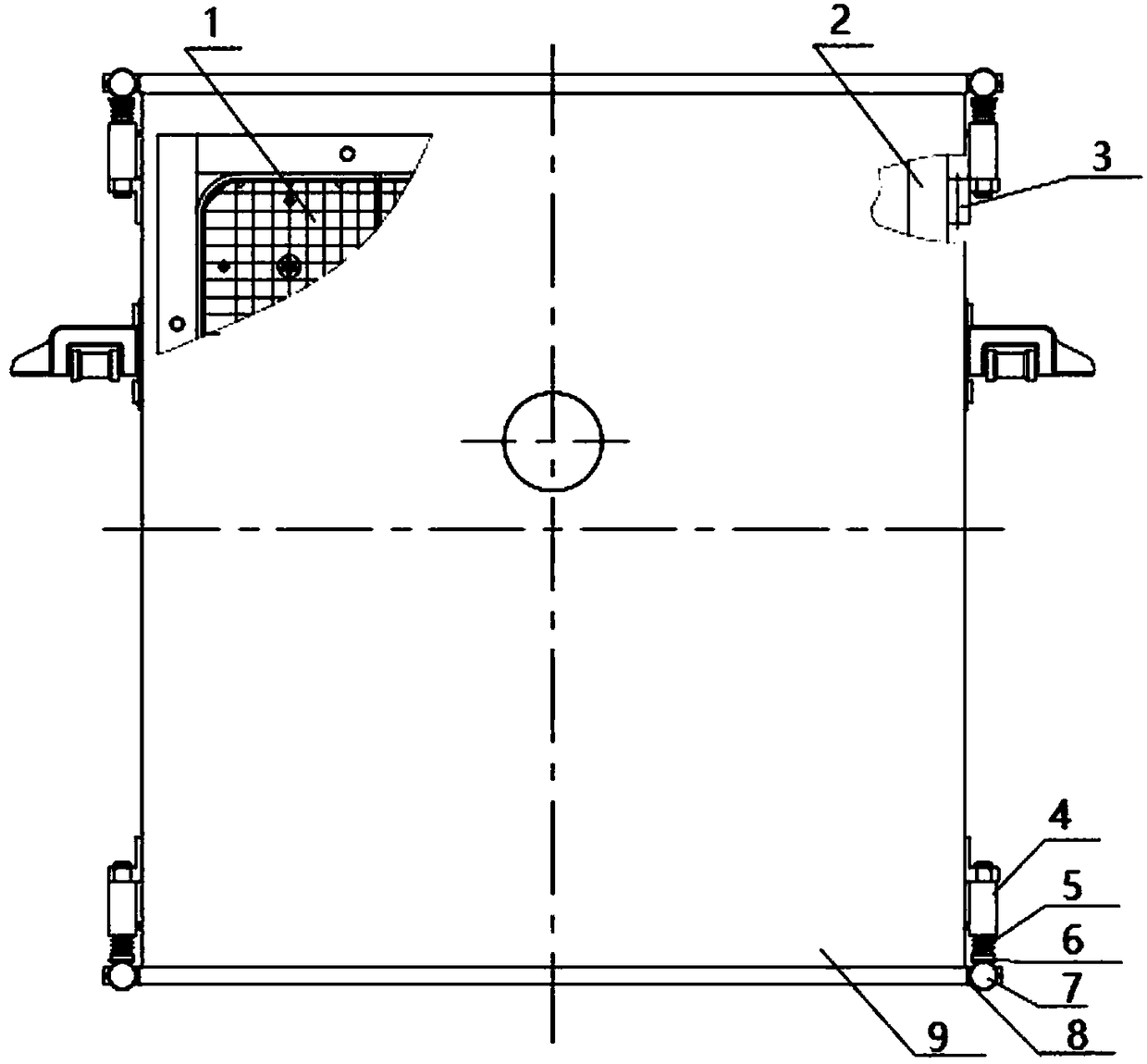

[0021] figure 1 As shown, the dehydration device includes: a filter chamber assembly part 1, a special filter cloth 9 for the dehydrator, and a tensioning device for the filter cloth.

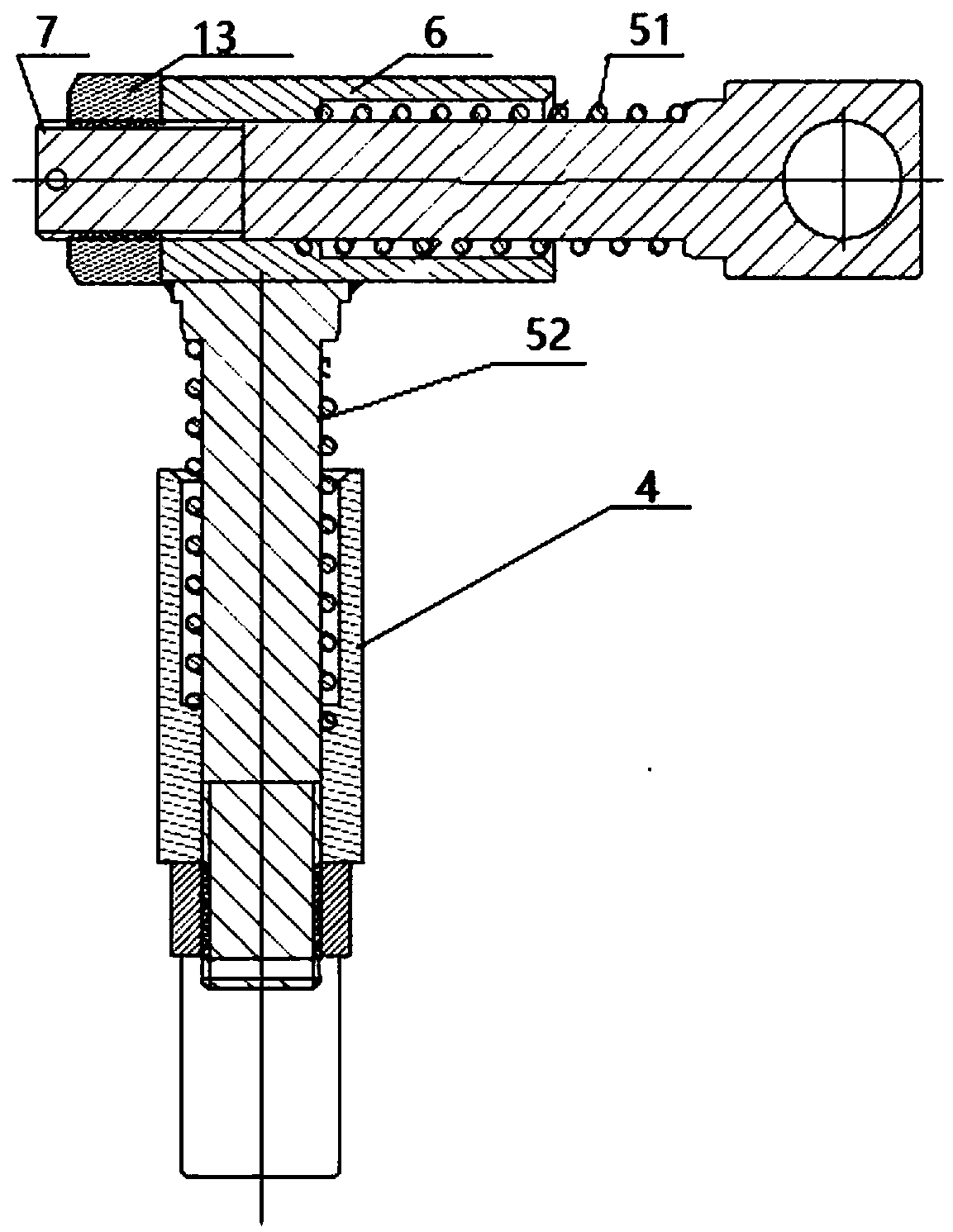

[0022] The installation pin shaft 3 of the filter cloth installation tensioning device is welded and installed on the moving plate 2 of the filter chamber, the filter cloth tensioning device is installed on the installation pin shaft 3, and the filter cloth is hung on the four filter cloth installations through the filter cloth hanging pipe 8 on the tensioner.

[0023] The filter cloth installation tensioning device can be adjusted after installation, so that the special filter cloth 9 is parallel to the surface of the filter chamber, and the distance from the special filter cloth 9 to the filter chamber is subject to the ability to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com