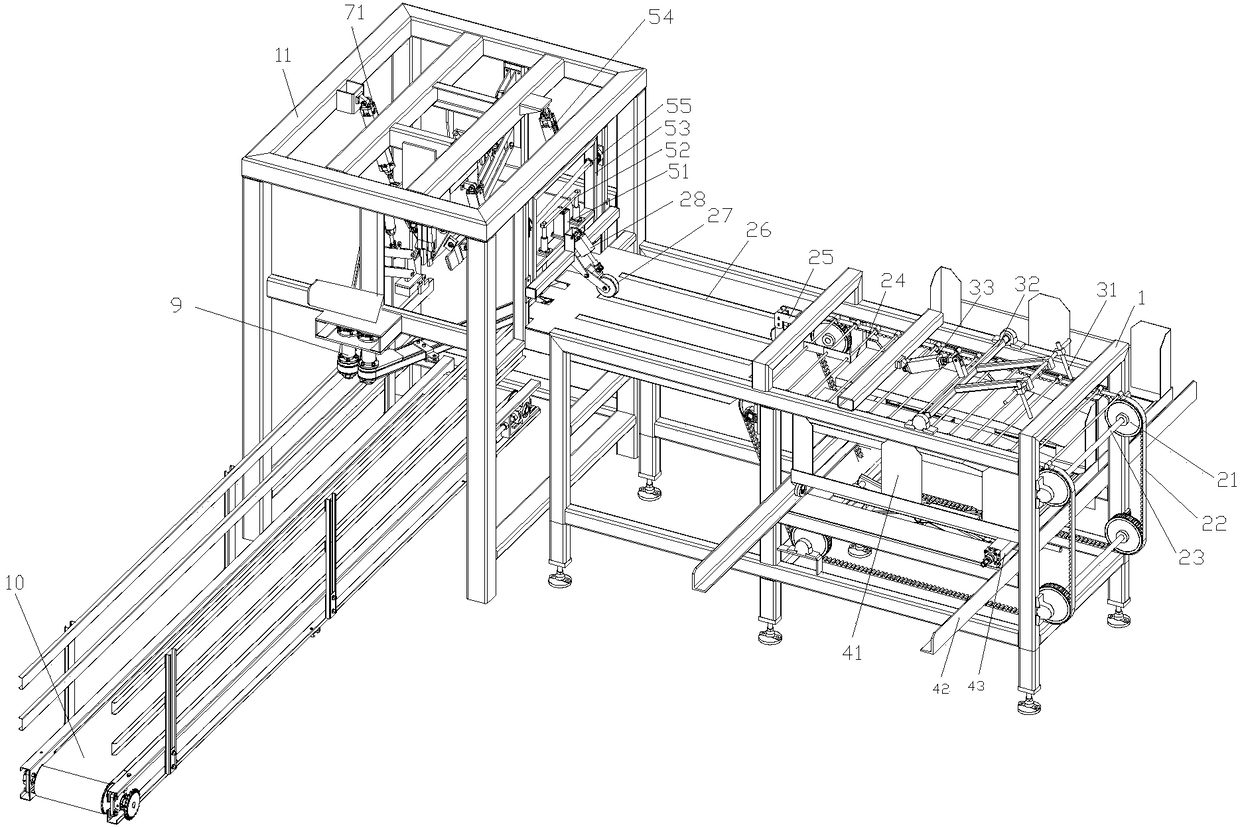

Full-automatic bag feeding packing machine

A fully automatic, bag-packing technology, applied in packaging and other directions, can solve the problems of unsatisfactory bagging effect, lack of bag sorting function, waste of manpower, material and financial resources, etc., to save working time, reduce working steps, and reduce labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

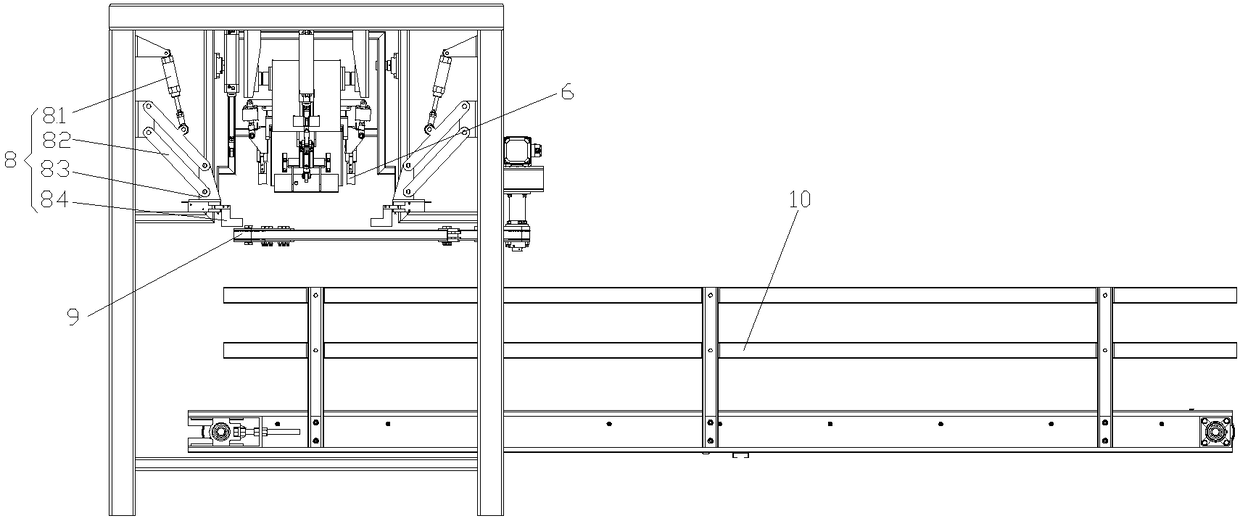

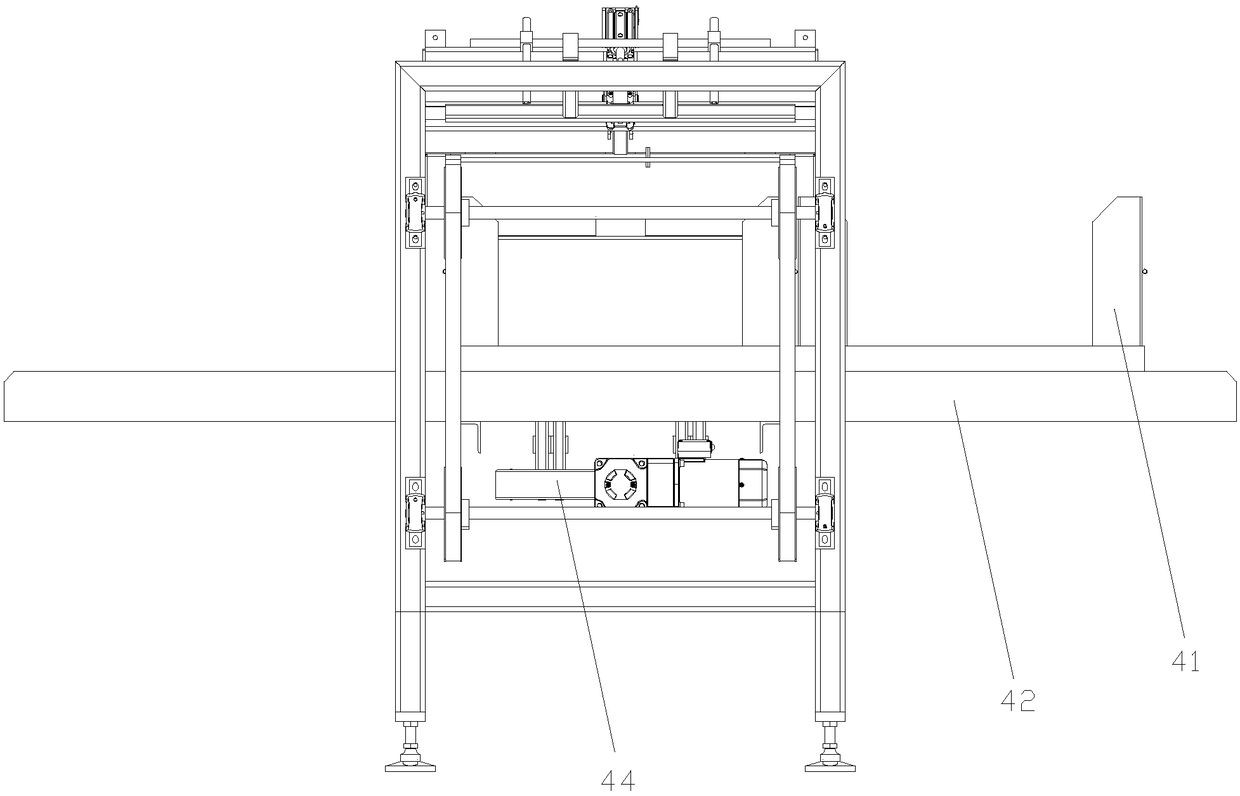

[0025] refer to Figure 1-4 , a fully automatic bagging packaging machine, comprising two frames, a bag storage mechanism, a bag taking mechanism, an empty bag conveying mechanism, a bag opening mechanism, a bag clamping mechanism, a sewing bag conveying mechanism, a sealing device and a guiding device, the described The storage bag mechanism comprises two storage bag warehouses (41), slideway (42), the 3rd cylinder (43), lifting device (44), is fixed mutually between two storage bag warehouses (41), and described sliding Road (42) is fixed on the front end middle part of the first frame, and the storage bag warehouse (41) is slidably arranged on the slideway (42), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com