Wing leading edge structure, forming mold and preparation method thereof for micro-miniature unmanned aerial vehicle

A micro-wing technology, applied in the field of drones, can solve the problems of increasing workload, thickening, increasing structural weight and production and processing workload, so as to reduce the weight of thickening and reduce the workload of grinding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

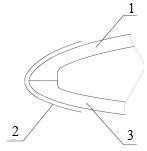

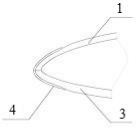

[0023] The leading edge structure of the airfoil is composed of the upper wall panel 1 of the wing surface, the lower wall panel 3 of the wing surface, and the middle 0.1mm thick aramid fiber cloth 4. There is a layer of 0.125mm thick carbon fiber cloth on the inner surface and outer surface of the upper wall panel 1 and the lower wing panel 3 respectively, and a 2mm thick PMI foam in the middle.

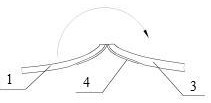

[0024] Manufacturing involves molds such as Figure 4 As shown, the surface of the airfoil and the lower wall plate are integrated together, the upper wall plate is turned 180° along the separation axis of the leading edge of the airfoil, and the leading edge of the upper wall plate is close to the leading edge of the lower wall plate along the separation axis , the mold is a solid structure, and the material is aluminum alloy. When using it, a layer of 0.1mm thick aramid cloth is symmetrically spread on the middle axis of the mold, and then a 0.125mm thick carbon fiber is laid on t...

Embodiment 2

[0026] The leading edge structure of the airfoil is composed of the upper wall plate 1 of the airfoil, the lower wall plate 3 of the airfoil and the middle 0.1mm thick nylon cloth 4. The inner surface and the outer surface of the plate 1 and the lower wall plate 3 of the airfoil each have a layer of 0.125mm thick carbon fiber cloth, and the middle is a 2mm thick PMI foam.

[0027] Manufacturing involves molds such as Figure 4 As shown, the surface of the wing surface and the lower wall plate are integrated together, the upper wall plate is turned 180° along the separation axis of the front edge of the wing, and the front edge of the upper wall plate is close to the front edge of the lower wall plate along the separation axis. The back of the mold is designed In order to reduce the groove structure, the material is steel. When using it, a layer of 0.1mm thick nylon cloth is laid symmetrically on the middle axis of the mold, and then a 0.125mm thick carbon fiber cloth is laid o...

Embodiment 3

[0029] The leading edge structure of the airfoil is composed of the upper wall panel 1 of the wing surface, the lower wall panel 3 of the wing surface, and the middle 0.1mm thick aramid fiber cloth 4. There is a layer of 0.125mm thick glass fiber cloth on the inner surface and outer surface of the upper wall panel 1 and the wing lower wall panel 3 respectively, with a 2mm thick PMI foam in the middle.

[0030] Manufacturing involves molds such as Figure 4 As shown, the surface of the airfoil and the lower wall plate are integrated together, the upper wall plate is turned 180° along the separation axis of the leading edge of the airfoil, and the leading edge of the upper wall plate is close to the leading edge of the lower wall plate along the separation axis , the mold is a solid structure, and the material is aluminum alloy. When using it, a layer of 0.1mm thick aramid cloth is symmetrically laid on the middle axis of the mold, and then a 0.125mm thick glass is laid on the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com