Gear machining device

A processing device and gear technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems affecting the normal drilling of drill bits, and achieve the effects of saving resources, improving cleaning effect, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further detailed explanation through specific implementation mode below:

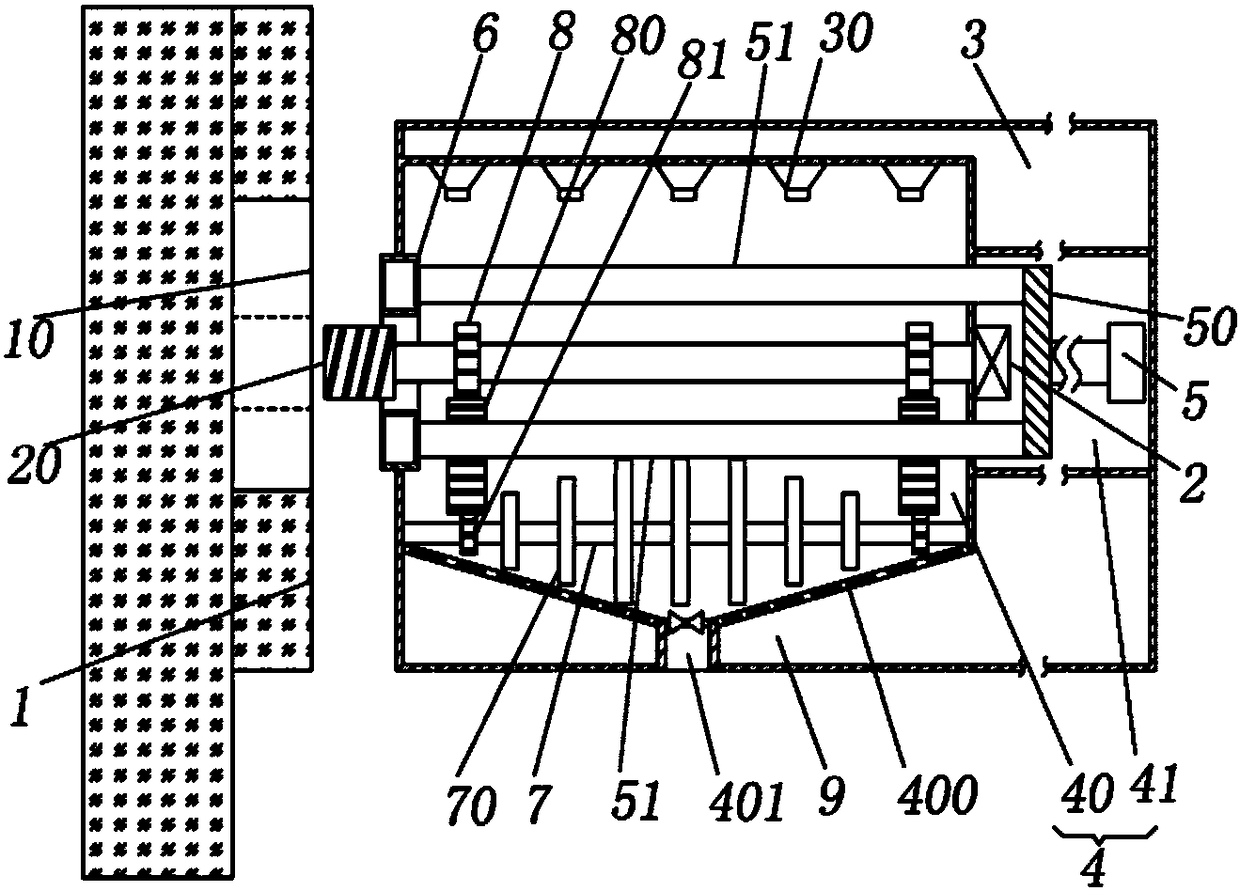

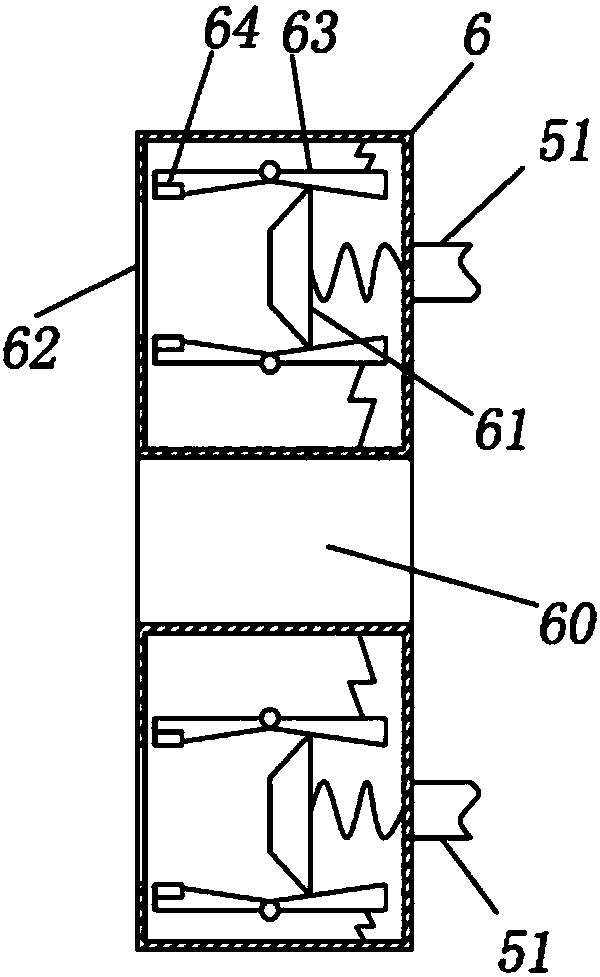

[0018] The reference signs in the drawings of the description include: three-jaw chuck 1, gear 10, motor 2, drill bit 20, cleaning liquid tank 3, cleaning nozzle 30, operation box 4, processing box 40, liquid leakage plate 400, chip discharge port 401, power box 41, hydraulic cylinder 5, fixed plate 50, sliding rod 51, electromagnet plate 6, through hole 60, electromagnet 61, suction port 62, special-shaped block 63, electromagnet sheet 64, rotating rod 7, crushing blade 70, driving gear 8, transmission gear 80, driven gear 81, waste water tank 9.

[0019] The embodiment is basically as figure 1 Shown: gear processing device, comprises motor 2 and drill bit 20, the left end of output shaft of motor 2 is fixedly connected with drill bit 20, also comprises cabinet, traction mechanism and crushing mechanism.

[0020] The chassis includes a cleaning liquid tank 3, a work tank 4 and a waste water ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com