Auto sheet metal dent restorer

A sheet metal and automobile technology, applied in the field of automobile sheet metal repair tools, can solve the problem of over-pulling the sunken sheet metal into a convex hull, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

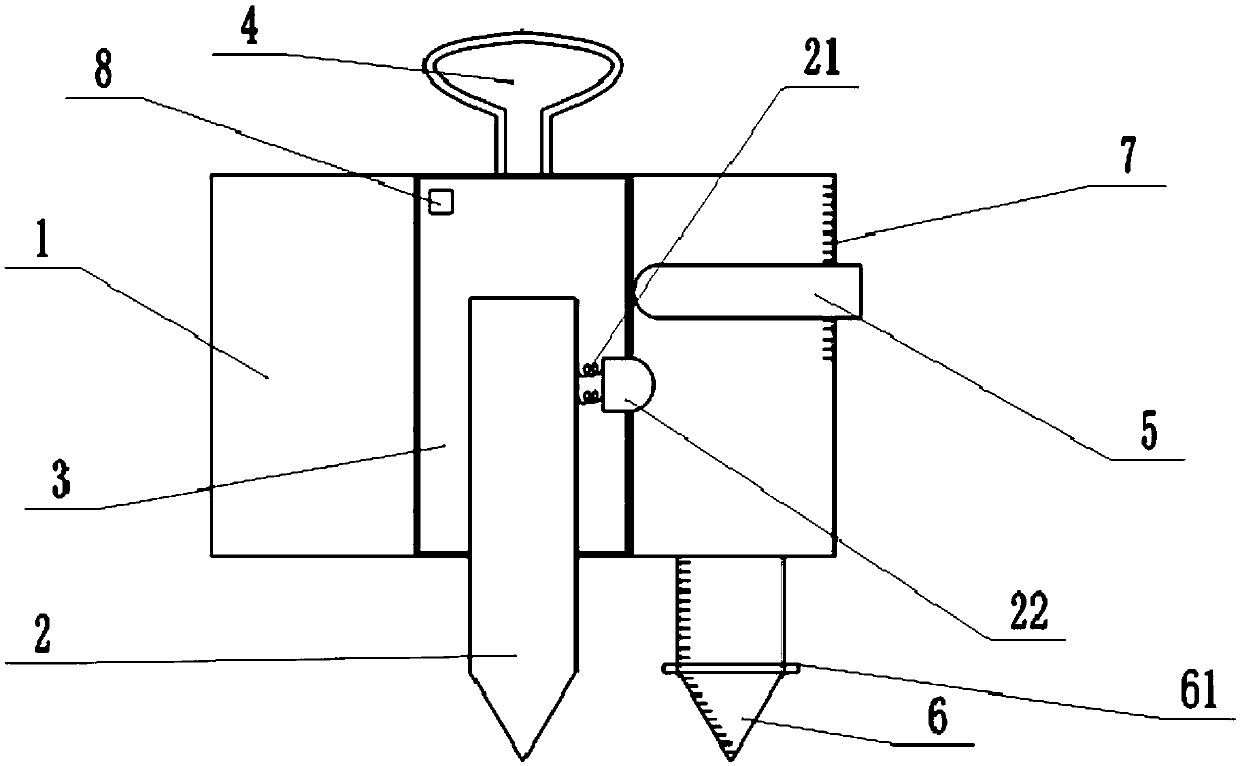

[0014] The reference signs in the drawings of the specification include: chute plate 1, elongated welding needle 2, spring 21, bump 22, cylinder body 3, handle 4, push block 5, detection head 6, reading plate 61, scale line 7 , Key switch 8.

[0015] The embodiment is basically as attached figure 1 Shown: an automobile sheet metal dent restorer, including a chute plate 1, a long welding needle 2, a cylinder 3 and a handle 4, the side of the cylinder 3 is provided with a key switch 8, and the key switch 8 is connected to There is a control cable, the control cable is connected with an electric welding machine, the elongated welding needle 2 is installed on the heating end of the electric welding machine, the elongated welding needle 2 is provided with a welding head, and the cylinder 3 is slidably connected to the sliding On the middle part of the slot plate 1, the elong...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com