Bearing lubricating device

A bearing lubrication and sliding hole technology, which is applied to bearing elements, shafts and bearings, and devices that apply liquid to surfaces, etc., can solve problems such as uneven lubrication and improve the effect of oiling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is further described in detail through specific implementation methods:

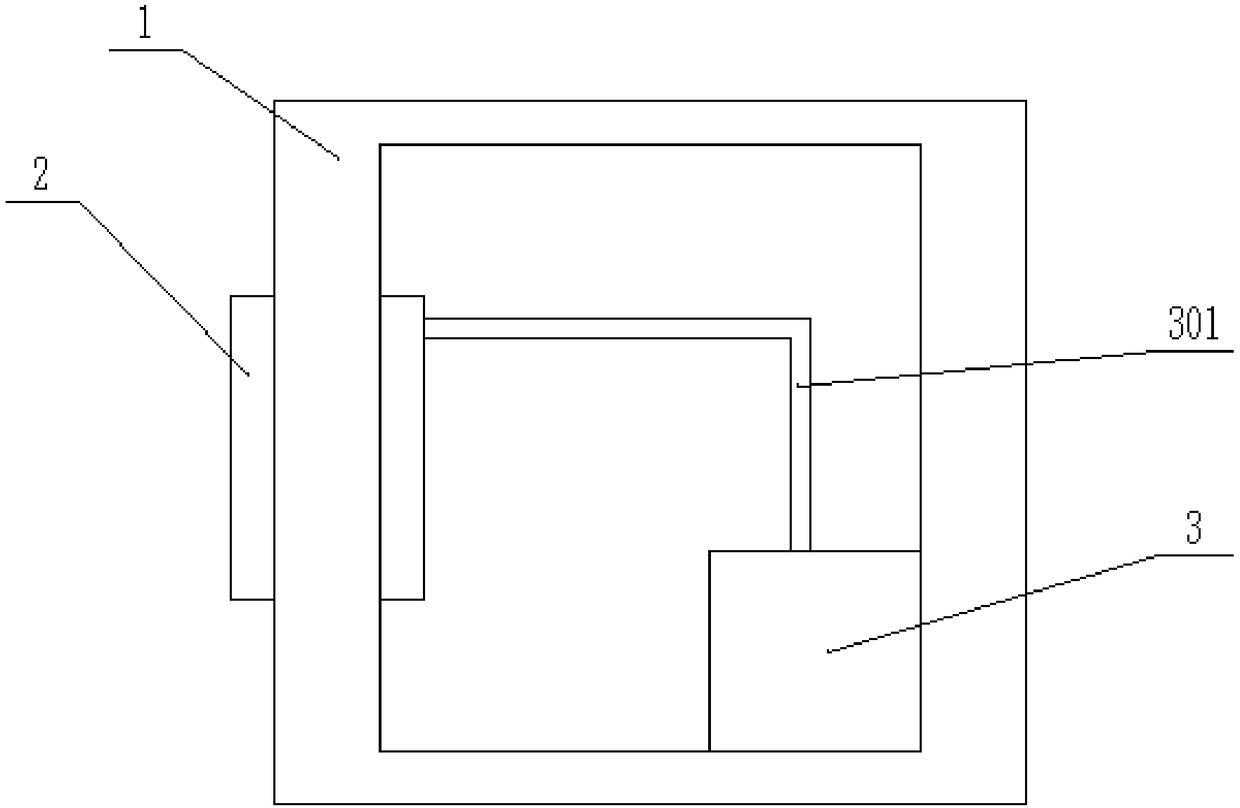

[0017] The reference signs in the drawings of the description include: frame 1, support base 2, first diversion hole 201, fuel tank 3, oil inlet pipe 301, electromagnet 4, oiling rod 5, second diversion hole 501, communication hole 502, oil outlet hole 503, block 504, magnet 505, extension spring 6, mobile platform 7, rotary platform 8, positioning shaft 9, runner 10, rotating shaft 11, motor 12.

[0018] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 Shown:

[0019] The bearing lubricating device includes a frame 1, a lubricating part and a rotating part. A slide rail is horizontally arranged on the frame 1. The lubricating part includes an oil tank 3, a support seat 2 and two oiling units symmetrically arranged up and down on the horizontal axis of the support seat 2. , the support seat 2 is in the shape of "匚", the support seat 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com