Shoe with coated welt

A wrapping and welt technology, which is applied to shoe uppers, footwear, boot legs, etc., can solve the problems of difficult application, difficult appearance design, and difficulty in using commercially available welt products, and achieves the effect of increasing the sense of design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

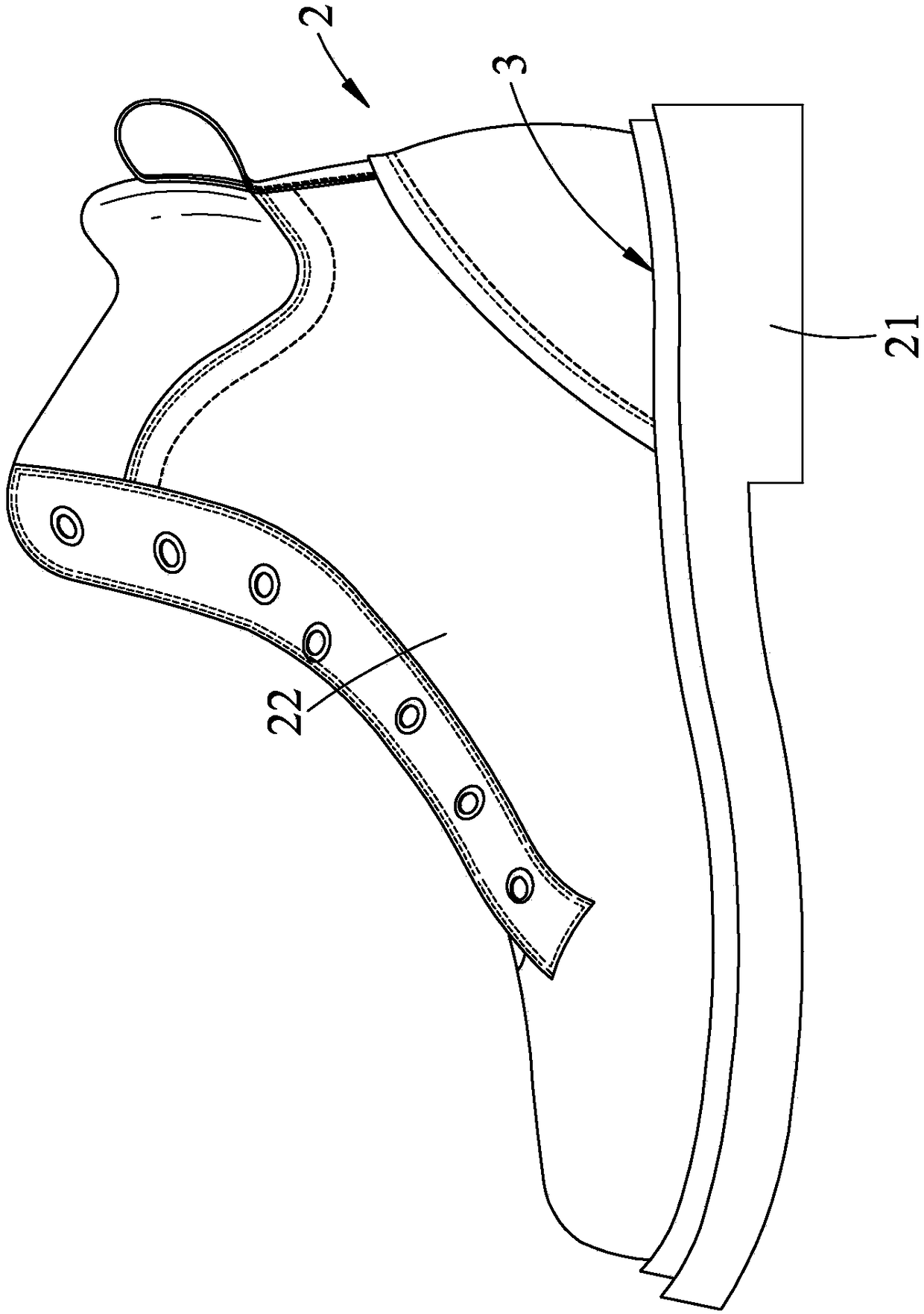

[0034] refer to image 3 , Figure 4 , is a first embodiment of the shoe 2 with a covered welt of the present invention, the shoe 2 includes a sole 21, a vamp 22 disposed on the sole 21, a vamp 22 disposed on the sole 21 and the vamp 22 between the midsole 23, and a welt 3 that is arranged on the top surface of the sole 21 and surrounds the bottom peripheral side of the vamp 22. In this embodiment, the welt 3 is complete and closed around the top surface of the sole 21, but it is not limited thereto. In other variations of this embodiment, the welt 3 can also be partly or partially The non-enclosed mode is arranged on the top surface peripheral side of the sole 21 .

[0035] refer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com