Toughening compound additive of polypropylene resin and preparation method of polypropylene anti-impact resin

A technology of polypropylene resin and compound additives, which is applied in the field of synthetic resins, can solve the problems of high difficulty, reduced impact strength, and low impact resistance of high-fluidity polypropylene, and achieve strong adaptability, maintain flexural modulus, and improve The effect of impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 50g benzoate and 35g lithium phosphate are put into the solution that is made up of butanone 300ml and ethanol 200ml and handle (stirring and impregnating after 2 hours filter dry, 60 ° of ℃ oven dry 2 hours), then benzoate and Lithium phosphate is taken out to obtain a composite toughening agent.

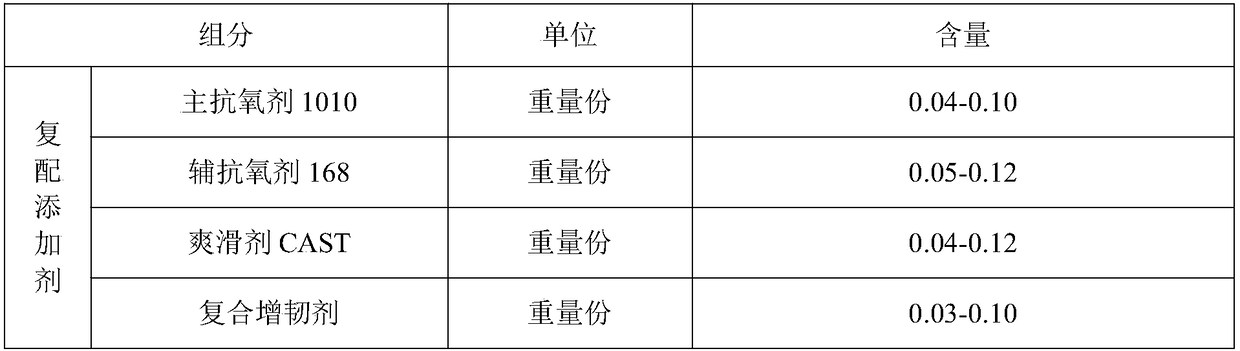

[0037] 120g of primary antioxidant 3-(3,5-bis-tert-butyl-4-hydroxycyclohexyl) propionate, 180g of secondary antioxidant (2,4-bis-tert-butylphenol) phosphite, cool 50 g of slip agent calcium stearate and 85 g of composite toughening agent were uniformly mixed to obtain 435 g of toughening composite additive of polypropylene resin.

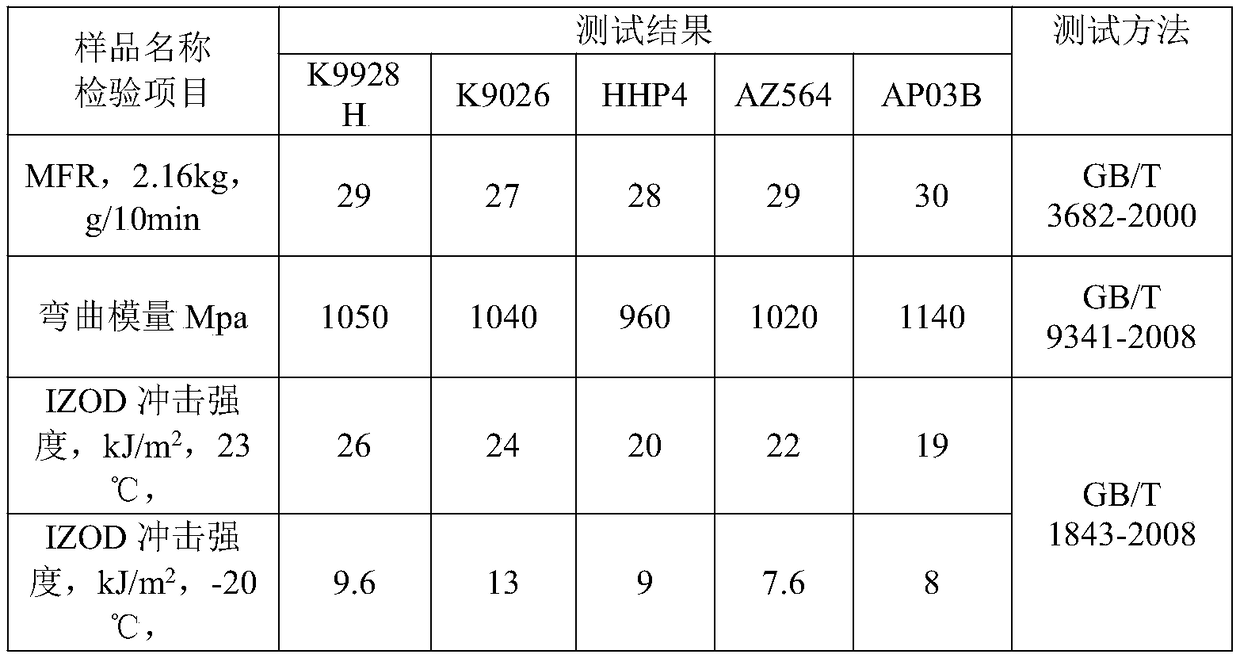

[0038] With the polypropylene carrier resin K9928H of 3000g, polypropylene carrier resin K9026, polypropylene carrier resin HHP4, polypropylene carrier resin AZ564 and polypropylene carrier resin AP03B respectively with the toughening composite additive of 20g by high mixer at normal temperature (without heating ) are mixed evenly, and then granu...

Embodiment 2

[0043] The difference from Example 1 is that the addition of the toughening compound additive is replaced by 20g to 15g, the impact performance is greatly improved, and the flexural modulus is smaller. The results are shown in Table 3 (15g addition):

[0044] table 3

[0045]

Embodiment 3

[0047] The difference from Example 1 is that the addition of the toughening compound additive is replaced by 20g to 30g, the impact performance is greatly improved, and the flexural modulus is smaller. The results are shown in Table 4 (30g addition):

[0048] Table 4

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com