Mold moving and jacking-out system of large injection mold and intermittent production method of large injection molding machine

A technology of injection mold and ejection system, which is applied in the field of large-scale injection mold shifting and ejection system, which can solve the problems of inability to realize continuous production, small products, structural stability, and positioning accuracy that cannot meet the production needs of large molds and products. Achieve the effect of uninterrupted operation, high positioning accuracy and reduced standby time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

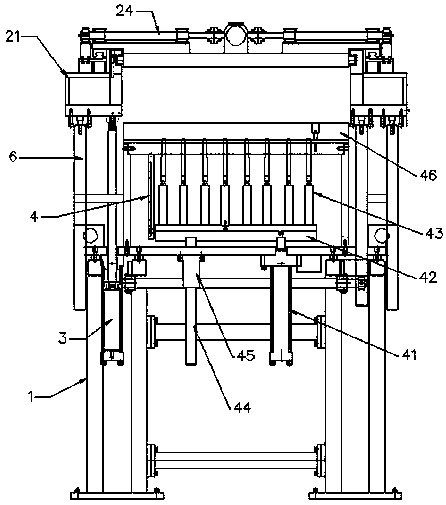

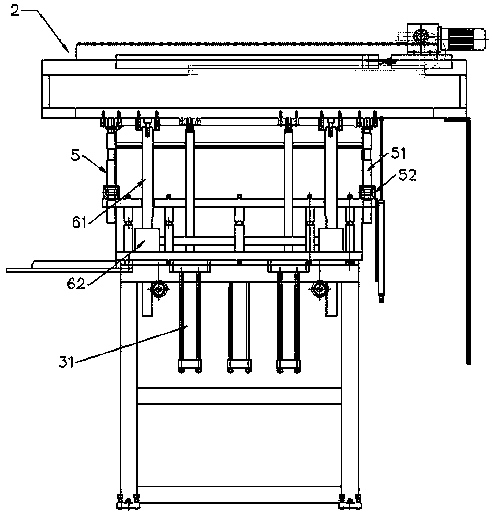

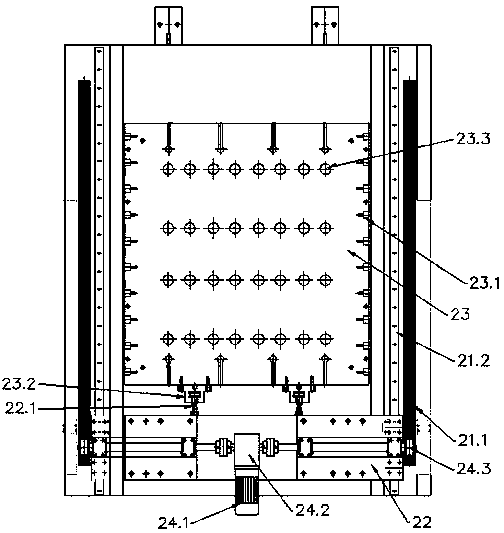

[0033] The following pairing is attached Figures 1 to 7 The embodiments of the present invention will be described in detail.

[0034] The large-scale injection mold shifting and ejecting system is characterized in that it includes a bracket 1, a horizontal mold shifting mechanism 2 that installs the mold and drives the mold to translate, a lifting mechanism 3 that is vertically arranged and installed on the bracket 1, and is installed on the bracket 1 for The ejection mechanism 4 that ejects the product in the mold, the horizontal mold moving mechanism 2 is located directly above the ejection mechanism 4, supported by the lifting mechanism 3, and the horizontal mold moving mechanism 2, the lifting mechanism 3 and the ejection mechanism 4 pass through The control system coordinates and controls in a unified manner. The horizontal mold-moving mechanism 2 includes two horizontally aligned and separated translation guide tables 21, a mold puller 22 arranged horizontally and inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com